Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In recent years, the industrial panini press has emerged as a beacon of innovation in the culinary world, reshaping the way restaurants and cafes approach sandwich preparation. This compact yet powerful appliance has transcended its traditional boundaries, becoming a versatile tool in the arsenal of commercial kitchens. As we delve into the fascinating journey of the industrial panini press, we discover a world of endless possibilities and technological advancements that are transforming the way we savor our favorite meals.

The culinary landscape has been forever altered by the rise of the industrial panini press, a game-changer that has not only revolutionized the way sandwiches are made but also expanded the possibilities for foodservice operations. Once a staple in small sandwich shops and delis, the industrial panini press has now become a staple in a variety of commercial kitchens, from cafes to hotels, and even in some high-end restaurants.

With its ability to quickly and consistently toast bread to perfection, the industrial panini press has become a must-have for any establishment looking to offer a variety of toasted sandwiches. The convenience and efficiency it brings to the kitchen have made it a favorite among chefs and kitchen staff alike.

One of the key factors contributing to the surge in popularity of the industrial panini press is its versatility. These presses are not just for making classic paninis anymore. They can handle a wide range of breads, from baguettes to brioche, and can accommodate fillings from simple ham and cheese to gourmet combinations that include avocado, prosciutto, and arugula. This flexibility has allowed chefs to experiment with new flavors and presentations, keeping their menus fresh and exciting.

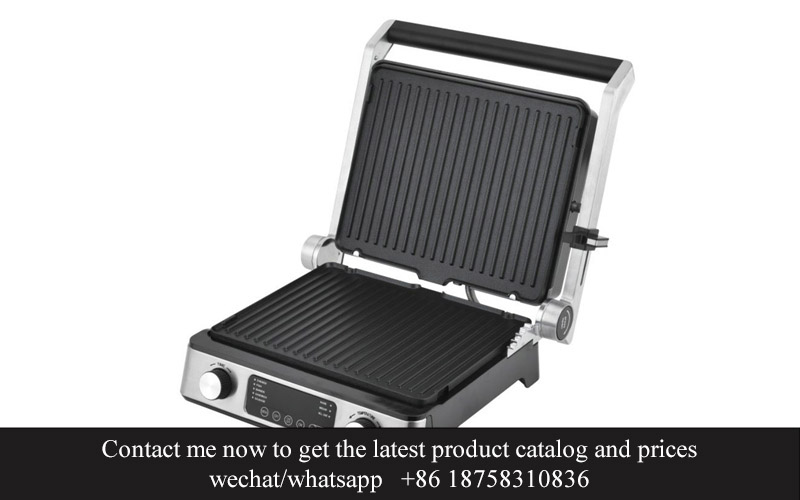

The design of modern industrial panini presses has also played a significant role in their rise. Many models now come with adjustable heat settings, allowing for precise control over the cooking process. Some even feature non-stick surfaces that make it easier to clean and maintain the press, which is a crucial factor in busy commercial kitchens. The sleek and modern look of these appliances also adds a touch of professionalism to any kitchen, enhancing the overall dining experience.

Another factor that cannot be overlooked is the convenience factor. The industrial panini press is a time-saver. It can toast and grill a sandwich in mere minutes, which is particularly beneficial during peak hours when speed of service is paramount. This efficiency means that restaurants can serve more customers in less time, increasing turnover and revenue.

Market trends have also played a part in the industrial panini press’s ascent. The demand for fast-casual dining has surged, and the panini press fits perfectly into this category. These sandwiches are portable, affordable, and can be customized to suit individual tastes, making them a hit with consumers looking for a quick, yet satisfying meal.

Data from market research firms supports the trend. Sales of industrial panini presses have been on the rise, with an increasing number of commercial kitchens opting for these versatile appliances. The numbers reflect the growing interest in offering a variety of toasted sandwiches, which has become a staple in the fast-casual segment.

The success of the industrial panini press is not just limited to the kitchen. It has also had a positive impact on the dining experience. The sight and smell of freshly toasted bread, coupled with the promise of a warm, melted cheese, can be irresistible to customers. The visual appeal of a perfectly grilled sandwich is hard to resist, and the industrial panini press delivers just that.

In addition to the obvious benefits, the industrial panini press has also opened up new opportunities for chefs to get creative. They can now offer a variety of sandwiches that are not only delicious but also visually appealing. The ability to add a layer of creativity to a simple sandwich has helped to elevate the category, making it a favorite among foodies and casual diners alike.

The industrial panini press has also become a symbol of innovation in the culinary world. As technology advances, these presses continue to evolve, offering new features and capabilities. Some models now come with programmable settings that allow for the creation of a wide range of recipes with a single press. This level of customization has made the industrial panini press a valuable tool for chefs looking to offer unique and consistent dishes.

In conclusion, the industrial panini press has become a game-changer in the culinary scene. Its versatility, efficiency, and ability to enhance the dining experience have made it a staple in commercial kitchens around the world. As the demand for fast-casual dining continues to grow, the industrial panini press is likely to remain a key player in the foodservice industry, bringing innovation and excitement to the sandwich category.

The industrial panini press has transcended its humble origins as a mere sandwich maker, evolving into a versatile and powerful tool that has found its way into a variety of commercial kitchens. It’s not just about pressing bread; it’s a culinary instrument that can revolutionize the way we think about fast food and casual dining.

With its sleek design and robust build, the industrial panini press is engineered to withstand the rigors of high-volume cooking. It’s a marvel of modern technology, featuring non-stick surfaces that ensure even heat distribution and easy release of food, making it a favorite among chefs for its ability to produce consistent results time after time.

But the capabilities of the industrial panini press go far beyond the standard ham and cheese sandwich. It’s capable of cooking a wide array of foods, from wraps and flatbreads to grilled cheese and paninis with a variety of fillings. The adjustable heat settings allow for precision cooking, ensuring that each dish is cooked to perfection, whether it’s a crispy exterior with a melty interior or a perfectly toasted crust.

The press itself is a marvel of engineering, with a locking mechanism that ensures the lid closes securely, trapping heat and steam to cook the food evenly. The design often includes a visible window that allows operators to monitor the cooking process without opening the lid, thus maintaining the integrity of the food and reducing the risk of overcooking.

One of the standout features of the industrial panini press is its ability to accommodate different sizes of food. Whether you’re serving a single guest or a crowd, these presses can handle a variety of shapes and sizes, making them a versatile addition to any kitchen. They’re also designed to be easy to clean, with removable parts that can be washed in a dishwasher, saving valuable time for busy kitchen staff.

The industrial panini press has also become a favorite among foodservice operators for its ability to enhance the presentation of food. The uniform browning and the attractive grill marks that the press imparts on the food can make even the simplest dishes look appetizing and professional.

Moreover, the press is not just for sandwiches. Chefs have been creative with its use, employing it to cook vegetables, meats, and even desserts. The press can create beautiful charred marks on vegetables, adding depth of flavor and a smoky taste that can elevate a dish from ordinary to extraordinary.

In the realm of breakfast items, the industrial panini press has become a staple for creating gourmet-style breakfast sandwiches. With the ability to cook eggs, bacon, and cheese together, it can produce a hot, satisfying breakfast in minutes, perfect for those looking for a quick and delicious start to their day.

The press also offers a health-conscious alternative to deep-frying. By using less oil and cooking at lower temperatures, it allows for the preparation of lighter, healthier options that still maintain the flavor and texture of fried foods.

Safety is another key aspect of the industrial panini press. Many models come with safety features such as cool-touch handles, automatic shut-off mechanisms, and non-slip bases to prevent accidents and ensure a safe working environment.

The industrial panini press has also become a favorite among food trucks and mobile vendors. Its compact size and portability make it an ideal choice for those who need to cook on the go, providing a consistent and high-quality product regardless of where they are serving.

In conclusion, the industrial panini press is more than just a sandwich maker; it’s a versatile, efficient, and innovative tool that has found its place in the hearts of chefs and foodservice professionals worldwide. Its ability to cook a wide range of foods, its ease of use, and its potential for culinary creativity make it an indispensable piece of equipment in any kitchen setting.

Modern industrial panini presses have evolved far beyond their humble origins as simple sandwich makers. These appliances now boast a range of innovative features designed to enhance efficiency, safety, and the quality of the final product. Here’s a closer look at some of the standout features that have made these presses a must-have in commercial kitchens.

Programmable Temperature Control: One of the most significant advancements in industrial panini presses is the ability to precisely control the cooking temperature. This feature allows chefs to set the exact heat level needed for different types of bread and fillings, ensuring that each sandwich is cooked to perfection with a consistent golden-brown exterior and a soft, warm interior.

Variable Pressures: Traditional panini presses apply a consistent pressure to flatten the sandwich, but modern models often offer adjustable pressure settings. This allows for a more tailored approach, ensuring that delicate breads like brioche or focaccia are handled with care while hearty sandwiches like Italian subs can be compressed firmly for a satisfying crunch.

Non-Stick Coatings: To prevent sticking and ensure easy release of the finished sandwich, many industrial panini presses are lined with non-stick coatings. This not only simplifies the cleaning process but also helps maintain the integrity of the fillings, preserving their textures and flavors.

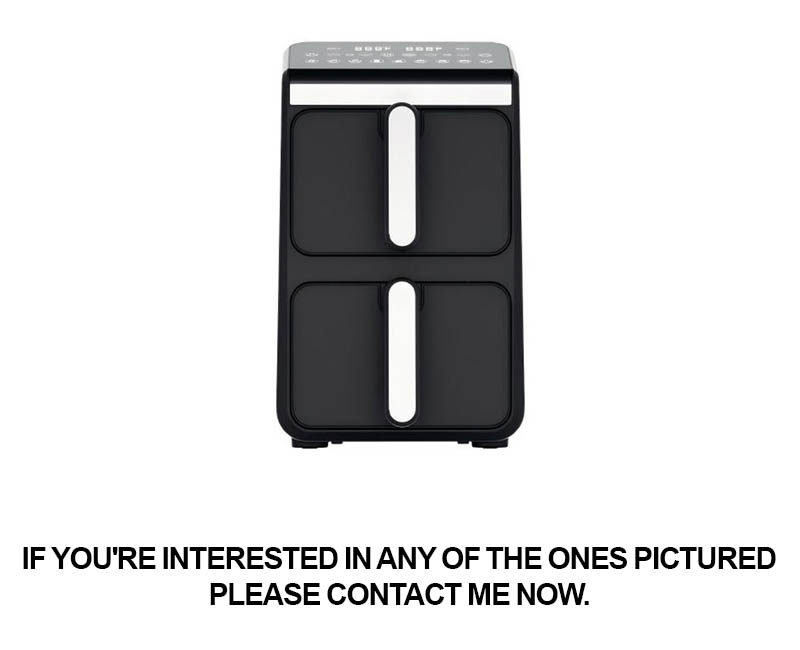

Multiple Cooking Functions: While the primary function of a panini press is to make sandwiches, modern units often come with additional cooking capabilities. Some models can be used to toast bread, grill vegetables, or even cook flatbreads and pancakes, making them a versatile addition to any kitchen.

Digital Displays and Controls: Many industrial panini presses now feature digital displays that allow users to monitor and adjust settings with ease. These screens provide clear readings on temperature and cooking time, ensuring that operators can keep track of the cooking process at a glance.

Safety Locks and Overheat Protection: Safety is a top priority in commercial kitchens, and modern industrial panini presses are designed with this in mind. Many models include safety locks to prevent accidental activation, as well as overheat protection systems that automatically shut off the press when it reaches a certain temperature, reducing the risk of fires and burns.

Quick Release Mechanisms: Time is of the essence in a busy kitchen, and the latest panini presses are designed to save valuable seconds. Many models feature quick-release mechanisms that allow operators to open the press with minimal effort, reducing the time it takes to prepare and serve sandwiches.

Stainless Steel Construction: For durability and ease of cleaning, many industrial panini presses are constructed from high-quality stainless steel. This material not only withstands the rigors of a commercial kitchen but also provides a sleek, hygienic appearance that complements modern kitchen aesthetics.

Removable Plates: For thorough cleaning and easy maintenance, some models offer removable plates. This feature allows operators to take the plates out of the press and clean them separately, ensuring that every nook and cranny is hygienically cleaned after each use.

Customizable Pressing Plates: Some industrial panini presses come with interchangeable pressing plates, allowing for a variety of sandwich shapes and sizes. This can be particularly useful for creating unique presentations or accommodating different customer preferences.

The evolution of the industrial panini press reflects a commitment to innovation and functionality. These appliances are no longer just for making sandwiches; they are versatile tools that can enhance the efficiency and quality of a commercial kitchen’s offerings. With their range of features, from precise temperature control to safety locks, these presses are a testament to how far kitchen technology has come and continue to be a valuable asset in the culinary industry.

In the bustling world of commercial cooking, the industrial panini press has emerged as a versatile and sought-after appliance. Its rise in popularity isn’t just a fleeting trend; it’s a testament to the evolving demands of the foodservice industry. Here’s a look at the market trends driving this surge in interest:

The demand for fast and efficient foodservice solutions has surged in recent years. Consumers are looking for quick service, especially during breakfast and lunch hours when time is of the essence. The industrial panini press perfectly fits this niche, allowing restaurants and cafes to serve freshly toasted sandwiches within minutes.

Health-conscious eating habits are on the rise, and the industrial panini press caters to this trend. By offering a healthier alternative to fried or greasy foods, it provides a solution for diners who want to indulge without compromising their dietary goals. The ability to use fresh ingredients and customizable options has made it a favorite among those who prefer to know exactly what’s in their meal.

With the rise of fast-casual dining, there’s an emphasis on quality over quantity. The industrial panini press not only delivers high-quality sandwiches but also adds a touch of culinary flair to the menu. Its ability to cook ingredients to perfection, with a golden-brown crust, makes it a standout option in a competitive market.

Technology has become a driving force in the foodservice industry, and the industrial panini press has embraced innovation. From programmable settings to non-stick surfaces, these presses are designed to enhance the cooking process and reduce the need for constant monitoring. This not only improves efficiency but also minimizes the risk of burning or overcooking.

The versatility of the industrial panini press cannot be overstated. It’s not just a sandwich maker; it’s a multipurpose cooking tool that can handle a variety of tasks. From grilled cheese to paninis, from open-faced sandwiches to flatbreads, its ability to cook a wide range of foods makes it a must-have for any establishment looking to expand its menu.

Cost-effectiveness is another key factor. While the initial investment might be higher than some other cooking equipment, the long-term savings in terms of time and labor are significant. The ability to produce multiple sandwiches simultaneously reduces wait times and increases the throughput of the kitchen.

In a world where sustainability is increasingly important, the industrial panini press is also environmentally friendly. With energy-efficient designs and durable construction, these presses are built to last and minimize waste. This aligns with the values of many businesses looking to reduce their carbon footprint.

The integration of the industrial panini press into mobile foodservice operations is another trend. With portable models available, food trucks, pop-up restaurants, and temporary food stalls can easily incorporate this appliance into their setup. This flexibility allows operators to adapt to different locations and events.

Finally, the consumer experience is at the heart of the market trends for industrial panini presses. With the ability to create unique and visually appealing sandwiches, operators are giving customers a reason to come back. The visual appeal of the press itself, often featuring a clear top for showcooking, adds an element of excitement to the dining experience.

The market trends driving the popularity of the industrial panini press are diverse and interconnected. From the need for speed and health to the demand for quality and technology, these factors are all contributing to its rise in the culinary scene. As the foodservice industry continues to evolve, the industrial panini press is poised to play a pivotal role in shaping the future of foodservice operations around the world.

In the world of commercial cooking, the rise of the industrial panini press has been a significant trend, and it’s not just about the simple act of pressing sandwiches. These machines, once confined to casual dining and fast-food establishments, have now become a staple in a variety of culinary settings. Here’s a look into the data-driven insights behind the surge in sales and usage of industrial panini presses.

The demand for these presses has surged as the demand for quick, convenient, and high-quality food options has grown. According to industry reports, sales of industrial panini presses have seen a steady increase over the past five years, with a compound annual growth rate (CAGR) of approximately 6%. This growth is attributed to several factors that have made the panini press a go-to appliance for restaurants and cafes.

One key driver is the trend towards healthier eating habits. Consumers are increasingly seeking meals that are not only fast but also offer healthier alternatives. The versatility of the industrial panini press allows for the preparation of a wide range of nutritious sandwiches, wraps, and flatbreads, which align perfectly with this dietary shift.

Another factor is the rise of gourmet fast-casual dining. These establishments pride themselves on offering premium-quality food that’s prepared quickly. The industrial panini press fits this model perfectly, allowing for the creation of custom-made sandwiches that are both visually appealing and delicious.

When it comes to usage statistics, the data paints a clear picture of how the industrial panini press is being integrated into various cuisines and kitchen environments. In fast-food chains, the presses are often used to serve popular items like paninis, grilled cheese, and veggie wraps. In delis and sandwich shops, they are used to craft artisanal sandwiches with fresh ingredients.

In the foodservice industry, the panini press has become a versatile tool for a variety of applications. It’s not uncommon to find these machines being used to prepare stuffed peppers, chicken fajitas, or even sushi rolls. The ability to customize and cook a diverse array of foods at high speeds has made the industrial panini press a must-have in many kitchens.

The sales data also reflects a shift in consumer preferences. There has been a noticeable trend towards “food-on-the-go” and convenience meals. With the industrial panini press, restaurants and cafes can offer a quick, hot meal that is perfect for customers who are pressed for time. The convenience factor is a major draw, as the press can cook a sandwich in just a few minutes, reducing wait times and increasing customer satisfaction.

In terms of sales, the most popular models of industrial panini presses are those with adjustable heat settings and non-stick surfaces. These features ensure that the press can handle a wide range of ingredients without sticking or burning. Additionally, the compact design and ease of cleaning make these machines a favorite among busy kitchen staff.

The statistics also show that the industrial panini press market is segmented by type, with countertop models being the most popular. This is due to their ease of use and flexibility in various kitchen layouts. However, there has been a growing interest in countertop convection ovens that can be used for a wider range of applications beyond sandwiches.

When examining the geographic distribution of sales, it’s clear that North America is the leading region for industrial panini presses, driven by the robust fast-food and fast-casual dining markets. Europe is following closely behind, with a growing number of restaurants embracing the convenience and efficiency of these presses.

The data-driven insights into the sales and usage of industrial panini presses highlight not only the growth in popularity but also the adaptability of the technology to meet the changing demands of the foodservice industry. As consumers continue to seek out convenient and healthy meal options, the industrial panini press is poised to remain a key player in the culinary landscape.

Industrial panini presses have become a staple in commercial kitchens across the globe, offering a unique blend of functionality and convenience. Their versatility is a testament to their popularity, as these appliances can handle a variety of tasks beyond just making sandwiches. Let’s delve into the myriad ways these presses are being used creatively in commercial kitchens.

Baking and Toasting Beyond BreadOne of the most common uses of industrial panini presses is to toast bread and create a variety of sandwiches. However, their heat and pressure can also be utilized to bake items like pastries, focaccia, and even pizza bases. The even distribution of heat ensures that these baked goods come out crispy on the outside and perfectly golden on the inside.

Grilling Vegetables and SeafoodThe high heat and direct contact with the press plates make it ideal for grilling vegetables and seafood. By using different toppings and marinades, chefs can create a variety of grilled dishes that offer a smoky, charred flavor profile. This technique is particularly popular for preparing vegetarian and vegan meals, as it adds depth to the flavor without relying on meat.

Crafting Customized BurgersIndustrial panini presses are not just for sandwiches; they’re also perfect for crafting gourmet burgers. The presses can seal in the juices and create a perfectly cooked, crispy crust on both sides of the burger patty. This feature allows for the preparation of handcrafted burgers with a variety of fillings, cheeses, and toppings, enhancing the overall dining experience.

Creating Mini-Desserts and AppetizersThe versatility of industrial panini presses extends to the realm of desserts and appetizers. Chefs can use them to create mini quiches, stuffed peppers, and even mini pizzas. The compact size of these dishes is perfect for serving at buffets, catering events, or as a unique addition to a regular menu.

Prepping Sausages and Cold CutsThe even cooking temperature and pressure of a panini press are excellent for preparing sausages and cold cuts. Whether you’re searing links or ensuring that prosciutto is perfectly crisp, these presses offer a quick and efficient way to prepare these dishes, which are often the stars of many a meal.

Customizing Wraps and WrapsFor a more interactive dining experience, industrial panini presses can be used to customize wraps and wraps on the spot. Guests can choose their fillings, which are then pressed to seal in the flavors and heat the ingredients. This approach not only adds an element of fun but also allows for a wide array of personalized menu options.

Cooking Breakfast ItemsThe versatility of industrial panini presses is not limited to lunch and dinner; they can also be used to prepare breakfast items. From breakfast sandwiches to grilled bacon and eggs, these presses can handle the heat and pressure required to cook a variety of breakfast favorites.

Innovative Cooking TechniquesChefs are constantly looking for new ways to impress customers, and the industrial panini press offers an array of innovative cooking techniques. From making pressed sandwiches with unconventional fillings to experimenting with different bread and wrap options, the possibilities are endless.

Eco-Friendly CookingWith increasing awareness of environmental issues, commercial kitchens are looking for eco-friendly ways to operate. Industrial panini presses use less energy than traditional grills and ovens, making them a more sustainable choice for commercial kitchens looking to reduce their carbon footprint.

Ease of Cleaning and MaintenanceIn the fast-paced environment of commercial kitchens, cleaning up efficiently is crucial. Industrial panini presses are designed with ease of cleaning in mind, featuring removable parts and surfaces that can be wiped down quickly. This not only saves time but also ensures that the presses are ready to go for the next batch of dishes in no time.

The versatility of industrial panini presses in commercial kitchens is a game-changer for chefs and restaurateurs alike. From the traditional to the avant-garde, these appliances are expanding the culinary possibilities and offering a myriad of ways to delight diners with both familiar and novel dishes.

In the world of commercial kitchens, the industrial panini press has become a versatile tool that transcends its sandwich-making roots. Let’s delve into how it has found success across various industries.

The hospitality industry has fully embraced the industrial panini press for its ability to serve a variety of grab-and-go meals. Fast-food restaurants have utilized these presses to craft quick, yet delicious, paninis and wraps, adding a unique twist to their menu. Hotel breakfast bars have seen an increase in guest satisfaction as the presses offer a convenient way to prepare fresh and appetizing items in a timely manner.

Gourmet cafes have taken the concept a step further, using the industrial panini press to experiment with artisanal ingredients and creative flavor combinations. The ability to seal in the juices and aromas of gourmet cheeses, cured meats, and house-made spreads has opened up new culinary horizons, appealing to a discerning clientele seeking unique and high-quality snacks.

Catering services have also found the industrial panini press to be a game-changer. It allows them to serve a range of panini and wrap options at events, ensuring that there’s something for every dietary preference and restriction. The portability and efficiency of the press mean that catering teams can produce a high volume of sandwiches quickly and with ease, whether at outdoor festivals, corporate events, or intimate weddings.

Health and wellness facilities, such as juice bars and salad shops, have started incorporating the industrial panini press into their menu. It offers a novel way to present their healthy offerings by sealing in the goodness of ingredients like avocado, cucumber, and sprouts. This not only adds a gourmet touch but also makes these meals more appealing and less like a traditional salad or wrap.

Sports arenas and concert venues have long been venues for the industrial panini press’s prowess. They cater to a large, diverse crowd with varying tastes, and the press can churn out a variety of sandwiches to satisfy different cravings. Whether it’s a savory ham and cheese or a sweet and fruity dessert sandwich, the press ensures that patrons can enjoy their food on the go without compromising on quality.

Schools and educational institutions have also seen the benefits of the industrial panini press. With the rise of healthier school lunches, the press allows for the creation of nutritious and tasty sandwiches that students look forward to. It can also be used for educational purposes, teaching students about different ingredients and cooking techniques, making the lunch break more than just a mealtime.

In the foodservice sector, the industrial panini press has proven to be a cost-effective solution. It reduces the need for multiple cooking appliances and can often replace ovens, grills, and toasters. This not only saves space but also reduces energy consumption, making it an environmentally friendly choice for kitchen operators.

In the corporate sector, the industrial panini press has found a niche in providing healthy and convenient meal options during lunch breaks. With many businesses focusing on employee wellness, these presses can be used to serve up salads, wraps, and sandwiches that are both nutritious and satisfying.

The retail food industry has also embraced the industrial panini press. It allows delis and specialty shops to offer fresh, hot sandwiches that can be taken home or enjoyed on the spot. The versatility of the press means that these businesses can cater to the diverse preferences of their customers, from vegan and gluten-free to traditional and gourmet.

As the world continues to seek out quick, convenient, and high-quality food options, the industrial panini press has solidified its place as a key player in the commercial kitchen landscape. Its ability to deliver consistent results with a variety of ingredients makes it an indispensable tool for those looking to innovate their menu offerings and enhance the dining experience.

The feedback from home chefs has been nothing short of enthusiastic. Many have found that the industrial panini press has revolutionized their cooking experience at home. Here’s a glimpse into what they’re saying:

“Versatile and Fast” – One chef raves about the speed at which they can now prepare gourmet sandwiches for their family. “It’s like having a sandwich shop in my kitchen,” they exclaim, appreciating the even heat distribution and the ability to press a variety of fillings to perfection.

“The Perfect Texture” – Texture is everything in culinary art, and home chefs are thrilled with the consistency the industrial panini press delivers. “The crust is crispy, but the insides are tender and warm,” shares a frequent user. This feature is particularly praised for making vegan and gluten-free sandwiches that don’t compromise on taste or texture.

“Innovative Features” – Chefs are impressed with the innovations that set industrial panini presses apart from regular household models. “The adjustable pressure and temperature settings mean I can experiment with different types of bread and fillings,” notes a hobbyist chef. The adjustable press is also a hit, allowing for the creation of artisanal-looking sandwiches with a professional finish.

“Effortless Clean-Up” – Home chefs appreciate the ease of cleaning the industrial panini press. “It’s a breeze to wipe down, and the non-stick surface means no more stuck-on bread,” says a mother of two. This feature is a game-changer for those who prefer to spend more time enjoying their meals rather than cleaning up afterward.

“Perfect for Entertaining” – Chefs who often host dinner parties find the industrial panini press to be an excellent addition to their kitchen. “It’s great for making a variety of sandwiches quickly and efficiently, which is perfect for a crowd,” one chef explains. The press has become a hit at social gatherings, impressing guests with homemade gourmet sandwiches.

“Healthier Options” – Many home chefs are using the industrial panini press to create healthier versions of their favorite sandwiches. “I can control the amount of oil and sauce I use, and the press helps lock in the flavors,” shares a health-conscious chef. This has led to an increase in homemade sandwiches with fresh ingredients like avocado, grilled vegetables, and lean proteins.

“Cost-Effective” – Chefs are also talking about the cost-effectiveness of using an industrial panini press. “Instead of buying pre-made sandwiches from a store, I can make my own for a fraction of the cost,” says a budget-savvy chef. The ability to control portion sizes and ingredients is a significant advantage for those looking to manage their household expenses.

“Easy to Use” – User-friendliness is a common theme in the feedback. “The press is straightforward and easy to adjust,” comments a novice chef. The clear instructions and intuitive controls have made it accessible to those who might not be as confident in the kitchen.

“The Ability to Customize” – Home chefs love the level of customization that the industrial panini press offers. “I can make anything from classic ham and cheese to creative combinations with exotic ingredients,” boasts a adventurous chef. This versatility has sparked a wave of culinary creativity in the home kitchen.

In summary, home chefs are singing praises for the industrial panini press. Its combination of speed, texture, versatility, and health benefits has made it a must-have appliance for anyone looking to elevate their sandwich game. From quick meals to entertaining guests, this press is proving to be a valuable asset in the home kitchen.

The industrial panini press has become a staple in commercial kitchens, and maintaining its efficiency and longevity is key to ensuring it remains a reliable tool for chefs. Here are some essential tips for keeping your industrial panini press in top shape:

Regular Cleaning is Non-NegotiableAfter each use, it’s crucial to clean the press thoroughly. Food particles can stick to the surfaces, leading to burn marks and a shorter lifespan. Wipe down the exterior with a damp cloth and ensure the interior is free of any residue. For a deeper clean, use a non-abrasive cleaner that won’t scratch the surfaces.

Check the Seals RegularlyThe seals are what make the panini press so effective at cooking the bread evenly. Over time, they can become worn or damaged, which affects the press’s performance. Inspect the seals for any signs of wear, and replace them if necessary. A good seal ensures that steam is distributed properly for the perfect panini.

Avoid OverheatingIndustrial panini presses are designed to cook at high temperatures, but overheating can lead to uneven cooking and even damage to the press. Keep an eye on the temperature gauge and adjust it as needed. If you notice that the press is running hotter than usual, it might be time to replace the heating element.

Use the Right Temperature SettingsEach type of food requires a specific temperature to cook properly. For instance, a ham and cheese sandwich will need a different setting than a vegetable panini. Experiment with the temperature settings to find the perfect balance for each recipe. Consistency in temperature ensures that your panini come out consistently delicious.

Protect the Non-Stick CoatingNon-stick coatings are a game-changer for easy cleaning and preventing food from sticking. However, they can be damaged by metal utensils or harsh chemicals. Always use plastic or silicone spatulas when flipping or removing food from the press. Also, avoid using abrasive cleaners or steel wool, which can scratch the surface.

Keep the Press Sealed When Not in UseWhen the panini press isn’t in use, it’s best to keep it sealed. This not only prevents dust and debris from accumulating but also helps maintain the press’s temperature. If you frequently open and close the press, consider a model with a built-in lid that seals automatically.

Avoid Continuous UseWhile industrial panini presses are built to handle high volumes, it’s important not to overwork them. Continuous use without adequate breaks can lead to overheating and potential damage. Plan your cooking schedule to allow the press to cool down between batches.

Use a Heat Resistant SurfaceWhen placing your panini press on a countertop or table, use a heat-resistant mat or trivet. This protects the surface from heat damage and prevents any accidental burns. It’s also a good practice to keep the press away from flammable materials like curtains or paper towels.

Keep the Heating Elements CleanThe heating elements are the heart of your panini press. Keeping them clean ensures that they distribute heat evenly. Use a soft cloth to wipe away any food residue, and if necessary, use a non-abrasive brush to remove stubborn particles. Regular cleaning of the heating elements can prevent the need for frequent replacements.

Listen to Your Panini PressLike any machine, your industrial panini press will give you signs when it’s not working right. If you notice a change in the cooking temperature, strange noises, or a delay in heating up, it’s time to investigate. Addressing these issues promptly can prevent more significant problems down the line.

By following these maintenance and efficiency tips, you can ensure that your industrial panini press remains a vital and reliable tool in your kitchen for years to come. Remember, a well-maintained press not only prolongs its life but also guarantees consistent, high-quality results every time you press a sandwich.

The industrial panini press has come a long way since its inception, evolving from a simple sandwich-making appliance to a versatile tool that can revolutionize the way commercial kitchens operate. Here’s a glimpse into what the future might hold for this innovative technology.

Innovations in heat distribution have been a game-changer. Modern industrial panini presses now feature advanced heating elements that ensure even cooking across the entire surface of the sandwich. This uniformity not only guarantees a perfect outcome every time but also reduces the risk of burning or undercooking.

Smart sensors are becoming increasingly common in industrial panini presses. These sensors can adjust the heat output based on the type of food being cooked, ensuring that delicate ingredients like cheese or lettuce are not overcooked. This level of precision is a testament to the industry’s commitment to quality and customer satisfaction.

The design of industrial panini presses is also evolving to be more user-friendly. Many models now come with digital displays that provide real-time temperature readings and cooking time, making it easier for operators to monitor the process. Ergonomic handles and non-slip bases are also being integrated to improve safety and ease of use.

Energy efficiency is another area where we’re seeing significant advancements. Newer models are designed to use less energy while maintaining high performance, which is not only good for the environment but also for the bottom line of businesses that rely on these appliances.

The integration of technology is taking the industrial panini press to new heights. Some presses are now compatible with smart kitchen systems, allowing for remote control and monitoring. This connectivity means that chefs can manage their appliances from anywhere, which is particularly beneficial for busy kitchens with multiple stations.

The future of industrial panini press technology also involves the exploration of alternative cooking methods. With the rise of health-conscious consumers, there’s an increasing demand for healthier cooking options. Non-stick surfaces, steam-cooking capabilities, and air-frying functions are all potential additions to the next generation of industrial panini presses.

Customization is another trend that’s likely to influence future designs. Kitchens with diverse menus may require presses that can accommodate various sizes and shapes of food items. Some presses are already being developed with adjustable press plates that can cater to a wide range of ingredients.

The material used in the construction of industrial panini presses is also likely to change. Lightweight yet durable materials like stainless steel and aluminum are popular now, but there may be a shift towards materials that are even more resistant to wear and tear and easier to maintain.

In terms of safety, future industrial panini presses may include features such as automatic shut-off timers to prevent accidents and improve kitchen safety. These features could be linked to the overall kitchen management system, providing a comprehensive approach to kitchen safety.

The inclusion of health and wellness features is also a trend that’s expected to continue. Some presses might come with built-in temperature control systems that allow for sous-vide cooking, which is gaining popularity for its ability to lock in flavor and texture.

Finally, the future of industrial panini press technology may see a greater emphasis on sustainability. As businesses become more environmentally conscious, manufacturers may explore energy-saving modes and eco-friendly materials to reduce the carbon footprint of their products.

In summary, the future of industrial panini press technology is poised to bring about a host of new features and functionalities that will enhance the efficiency, safety, and versatility of these appliances. As consumer demands evolve and technology advances, the industrial panini press is set to become an even more integral part of the commercial kitchen landscape.