Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, one standout innovation has been the rapid advancement of air fryers. These devices have not only transformed the way we cook but have also spurred a wave of technological innovation in their assembly lines. As we delve into the realm of automated air fryer assembly, it’s fascinating to explore the journey of this technology, from its early stages to the cutting-edge systems of today. The impact of these advancements is profound, reshaping not just the manufacturing sector but also our daily lives in the kitchen.

In the ever-evolving landscape of kitchen appliances, the air fryer has emerged as a game-changer for health-conscious and culinary enthusiasts alike. Once a niche product, it has now become a staple in many households, offering a healthier alternative to traditional frying methods. This rise in popularity has sparked a demand for more efficient and innovative production methods, leading to the advent of the automated air fryer assembly line. Let’s delve into the fascinating world of the automated air fryer and understand its impact on our lives.

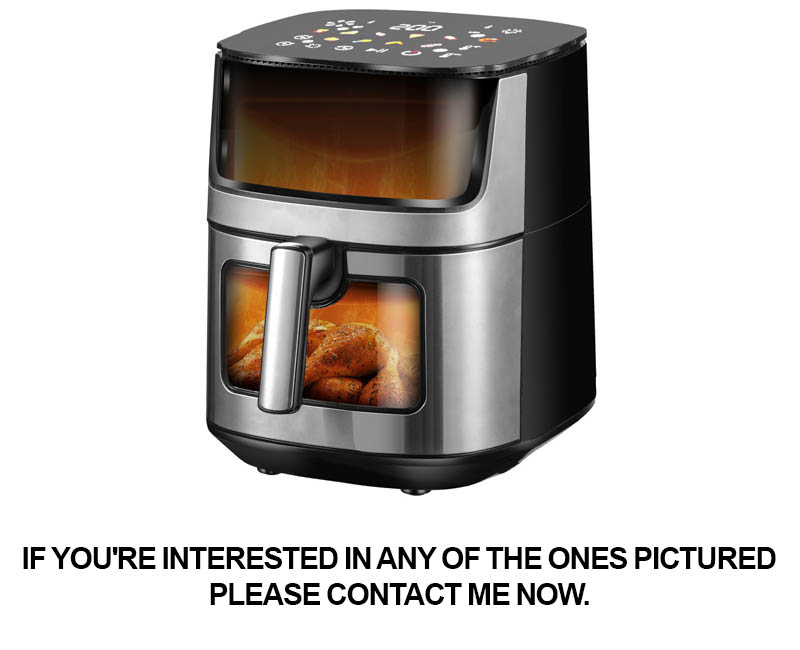

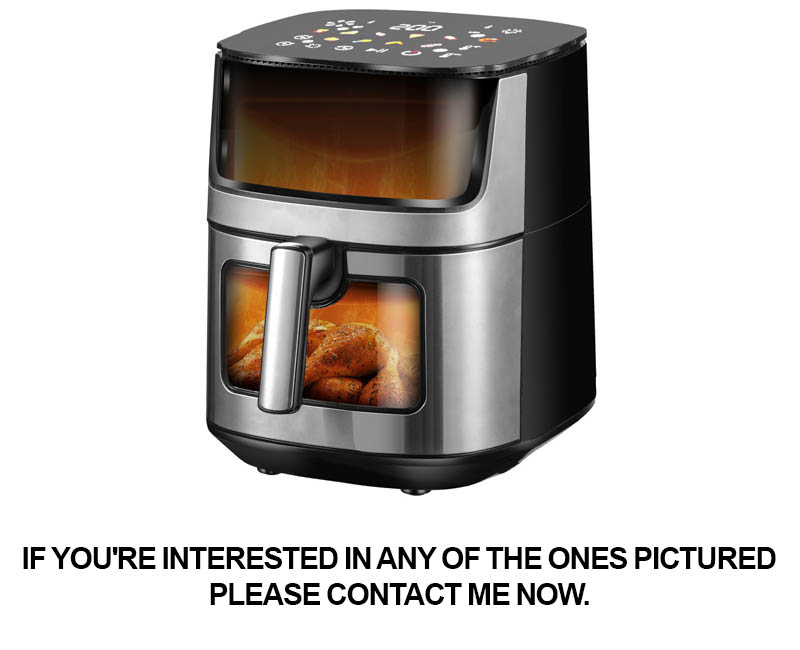

The concept of an air fryer is simple yet revolutionary. By utilizing hot air circulation, these appliances mimic the frying process without the need for excessive oil, thus reducing calories and fats in the final dish. This innovation has not only made cooking healthier but has also opened up a world of possibilities for creative chefs and home cooks.

The journey from the early days of air fryer invention to the sophisticated automated assembly lines we see today has been marked by significant advancements. Initially, the hand-crafted nature of air fryers limited their production and availability. However, as the demand grew, manufacturers sought ways to streamline the production process, ensuring consistent quality and faster delivery to consumers.

One of the standout features of modern automated air fryer assembly lines is the level of precision and control they offer. From the precise placement of components to the calibration of heating elements, every step is meticulously controlled by advanced machinery. This attention to detail ensures that each air fryer that rolls off the assembly line meets the high standards expected by consumers.

The heart of an automated air fryer assembly line lies in its machinery. Robots, automated conveyors, and computerized sensors work in harmony to perform tasks that were once the domain of skilled human labor. These machines are capable of handling the repetitive and precise assembly processes, such as securing parts, applying heat, and inspecting for quality control.

The process begins with the delivery of raw materials, which are meticulously sorted and inspected to ensure they meet the stringent quality requirements. The components then move along the assembly line, where robots deftly handle them, fastening parts and checking for alignment. Advanced sensors monitor the assembly process, detecting any anomalies that could indicate a faulty product.

As the air fryer takes shape, it moves through various stations. The heating elements are attached, and the electronics are integrated, all under the watchful eye of automated systems. The cooking chamber is sealed, and the exterior is coated with a durable finish, all part of the meticulous assembly that ensures the appliance’s longevity and performance.

Once the air fryer is fully assembled, it undergoes a series of tests to guarantee its functionality. This includes checking the cooking temperatures, the electrical connections, and the overall durability. These tests are not just about passing standards but also about providing consumers with a product that they can trust.

The automated assembly line has not only improved the efficiency of air fryer production but has also had a profound impact on the industry as a whole. By reducing the time it takes to produce each unit, manufacturers can meet the increasing demand for air fryers. This increased supply has, in turn, helped to drive down prices, making the health benefits of air fryers more accessible to a broader audience.

Moreover, the shift towards automation has opened up new opportunities for innovation. Designers and engineers can focus on creating more features and functionalities without worrying about the limitations of manual assembly. This has led to a range of air fryers with unique cooking capabilities, from adjustable temperature settings to programmable recipes.

The automated air fryer assembly line also reflects a broader trend in the kitchen appliance industry—making cooking more accessible and user-friendly. With features like digital displays and intuitive interfaces, even those without extensive culinary experience can enjoy the benefits of air frying at home.

In conclusion, the automated air fryer assembly line is a testament to human ingenuity and the relentless pursuit of efficiency. It has not only transformed the production of air fryers but has also enhanced the way we approach cooking and healthy eating. As the line continues to evolve, we can expect even more innovative and efficient appliances to grace our kitchens, making the future of cooking healthier and more enjoyable for all.

The air fryer, once a niche kitchen gadget, has now become a staple in many homes across the globe. This transformation didn’t happen overnight; it’s the result of a gradual evolution in the manufacturing process of these appliances. Let’s take a journey through the evolution of air fryer assembly lines, showcasing how technology and innovation have shaped this industry.

In the early days, air fryers were crafted by hand, with each unit being assembled and tested by skilled laborers. This process was time-consuming and limited in scale, as the production capacity was heavily dependent on the number of workers available. The emphasis was on quality, as each air fryer was a labor of love, but the cost was prohibitive for many consumers.

As demand for air fryers began to rise, manufacturers started to look for ways to streamline the production process. The introduction of semi-automated assembly lines marked a significant shift. These lines introduced conveyor belts, automated welding machines, and robotic screwdrivers to the process, reducing the need for manual labor and speeding up the production time. Quality control checks were also integrated, ensuring that each air fryer met the high standards set by the brand.

The mid-2000s saw a surge in technological advancements that began to revolutionize the air fryer assembly lines. The integration of computer numerical control (CNC) machines allowed for greater precision in the manufacturing of parts. Plastic injection molding machines became more sophisticated, enabling the production of lightweight and durable components. This era also brought about the use of barcode scanning systems, which improved inventory management and traceability.

The late 2010s brought us to the current state of air fryer assembly lines, where automation is king. Advanced robotics have taken over many of the repetitive tasks that were once performed by humans. Robots can now assemble, inspect, and package air fryers with a level of speed and consistency that would be unattainable by hand. These systems are designed to work in harmony, with sensors and software that can adjust to any variations in the product or process.

One of the most notable advancements is the use of artificial intelligence (AI) in the assembly process. AI algorithms can analyze data from the assembly line in real-time, predicting potential issues before they arise and suggesting improvements. This predictive maintenance not only reduces downtime but also ensures that the end product is of the highest quality.

The evolution of the air fryer assembly line has not only increased production efficiency but has also had a profound impact on the environment. By reducing waste and optimizing energy use, these automated lines are more sustainable than their predecessors. The use of renewable energy sources and recycling programs have further minimized the carbon footprint of air fryer production.

In terms of design, the assembly lines have also evolved to accommodate new and innovative features. The ability to quickly and easily integrate new technologies into the manufacturing process means that air fryers can be updated with the latest advancements in cooking technology. From adjustable temperature controls to smart connectivity, the possibilities are endless.

The evolution of the air fryer assembly line is a testament to the power of technology in transforming everyday products. What started as a simple kitchen gadget has now become a symbol of modern manufacturing prowess. As we continue to push the boundaries of what’s possible, it’s clear that the future of air fryers—and their assembly lines—will be even more exciting and efficient.

In the ever-evolving landscape of kitchen appliances, the assembly line for air fryers has undergone a remarkable transformation. Once a labor-intensive process, it has now been revolutionized by cutting-edge innovations that have not only streamlined production but also elevated the quality and efficiency of these popular cooking gadgets. Here’s a glimpse into some of the most notable advancements:

The integration of robotics has been a game-changer. Robots, equipped with precision and agility, now handle tasks that were once the purview of human workers. From picking and placing components to assembling intricate parts, these machines can operate tirelessly, reducing errors and increasing throughput. Advanced sensors and cameras ensure that each unit is assembled with pinpoint accuracy.

Smart sensors and IoT technology have made the assembly line more responsive and efficient. These sensors can detect any deviations from the standard process, alerting operators to potential issues before they become significant problems. The IoT aspect allows for real-time monitoring and control, enabling quick adjustments to optimize the production flow.

Automated quality control systems have become a cornerstone of modern assembly lines. These systems employ a combination of automated optical inspection (AOI), x-ray inspection, and other advanced techniques to ensure that every air fryer meets stringent quality standards. This not only minimizes the number of defective units but also reduces the need for post-production testing and rework.

The introduction of modular assembly systems has allowed for greater flexibility and scalability. These systems are designed to accommodate changes in product design or volume fluctuations without the need for extensive retooling. This modularity also makes it easier to adapt to new technologies and innovations, ensuring that the assembly line remains at the forefront of the industry.

Adaptive robotics is another innovation that’s gaining traction. These robots can learn and adapt to new tasks and environments, making them highly versatile. This means that as new components or processes are introduced, the robots can be quickly reprogrammed to handle them, reducing downtime and increasing the speed of production.

The use of 3D printing in the assembly line has opened up new possibilities. Complex components that were previously difficult or expensive to manufacture can now be created on-demand using 3D printing technology. This not only reduces the inventory costs but also allows for customization, as specific designs can be produced without the need for large-scale production runs.

Energy-efficient automation is also a key focus. With the growing importance of sustainability, manufacturers are looking for ways to reduce energy consumption without compromising productivity. Advanced motors, sensors, and controls are being used to optimize energy use throughout the assembly process, contributing to a greener and more sustainable manufacturing environment.

Software integration plays a crucial role in the modern assembly line. Customized software solutions are being developed to manage every aspect of the production process, from inventory control to scheduling. This software not only improves efficiency but also provides valuable data that can be used to further refine and optimize operations.

Lastly, the adoption of AI-driven predictive maintenance is preventing costly breakdowns and unplanned downtime. By analyzing data from sensors and other sources, AI algorithms can predict when machinery is likely to fail, allowing for maintenance to be scheduled proactively rather than reactively.

These innovations have collectively raised the bar for air fryer assembly lines, leading to more efficient, cost-effective, and high-quality production. As technology continues to advance, it’s clear that the future of air fryer assembly will be even more impressive, promising even greater capabilities and efficiencies.

In the realm of kitchen appliances, the evolution of the automated air fryer assembly line has brought about a remarkable transformation. This shift from traditional manufacturing methods to advanced automation has several key benefits that not only enhance productivity but also elevate the quality and sustainability of the final product. Here’s a closer look at these advantages:

Efficiency and SpeedAutomation has significantly boosted the efficiency of air fryer assembly lines. With the integration of robotic systems, the process is now streamlined, allowing for rapid production without compromising quality. The precision and speed of automated systems mean that more units can be manufactured in a shorter amount of time, meeting the growing demand for air fryers in the market.

Consistency in QualityOne of the most notable benefits of the automated assembly line is the consistency it brings to the production process. Each component is meticulously handled and assembled by machines, ensuring that every air fryer meets the same high standards. This level of uniformity is difficult to achieve with manual labor, where human error can introduce inconsistencies.

Reduced Labor CostsThe deployment of automated systems has also led to a reduction in labor costs. While the initial investment in robotics can be substantial, over time, the cost savings from decreased labor requirements and increased output can be substantial. Moreover, companies can redirect their workforce to more complex tasks that require human intuition and creativity, further enhancing productivity.

Enhanced SafetyManual assembly lines can be hazardous, with the risk of injuries from repetitive tasks or from handling sharp tools. Automation reduces these risks, creating a safer working environment. Workers are no longer exposed to the dangers associated with lifting heavy objects or working with machinery, which not only protects them but also minimizes the company’s liability.

Customization and FlexibilityAutomated assembly lines are highly adaptable, allowing for quick changes in production. This flexibility means that companies can respond to market demands by customizing air fryers with different features, sizes, or colors. The ease of reprogramming and adjusting the assembly process ensures that the production line can cater to a wide range of customer preferences without significant downtime.

Precision and Error ReductionMachines are programmed to perform tasks with extreme precision, eliminating the potential for human error that can occur during manual assembly. This precision is crucial in the assembly of electronic components and the intricate design of air fryers. The result is a product that performs consistently and reliably, providing consumers with a high-quality appliance.

Waste ReductionAutomated systems are designed to minimize waste. From the precise cutting of materials to the efficient use of resources, these lines help to reduce scrap and unused parts. This not only reduces costs but also aligns with the growing trend towards sustainability and environmental responsibility.

Real-time Data and MonitoringModern automated assembly lines are equipped with sensors and software that provide real-time data on the production process. This allows for continuous monitoring and adjustments to ensure that quality standards are met and that any issues can be addressed immediately. The data-driven approach also enables predictive maintenance, reducing downtime and extending the life of machinery.

Continuous ImprovementThe automated assembly line is not a static solution; it is a platform for continuous improvement. With the ability to collect and analyze vast amounts of data, companies can continually refine their processes, identify bottlenecks, and implement changes that lead to even greater efficiency and product quality.

In conclusion, the automated air fryer assembly line offers a multitude of benefits that resonate with both the manufacturer and the consumer. From increased efficiency and quality to reduced costs and waste, these advancements are driving the industry forward and setting new standards in the world of kitchen appliances.

The air fryer market has been experiencing a surge in popularity, driven by health-conscious consumers and the growing preference for convenient cooking solutions. Let’s delve into the insights and trends shaping this dynamic sector.

Consumers are increasingly seeking appliances that offer healthier cooking alternatives. Air fryers, with their ability to cook with minimal oil, have become a favorite among those looking to reduce their fat intake. This shift in consumer behavior has spurred innovation in the industry, leading to more advanced and user-friendly air fryer models.

The market is witnessing a trend towards larger capacity air fryers. Families and individuals who enjoy cooking for more than one person are gravitating towards these models, which can accommodate larger batches of food. This trend is not only driven by the need for convenience but also by the desire to enjoy communal dining experiences at home.

Smart technology integration is another significant trend. Air fryers with Wi-Fi capabilities and smartphone apps allow users to control their appliances remotely, receive recipe suggestions, and even monitor cooking progress from their phones. This level of connectivity is appealing to tech-savvy consumers who appreciate the blend of convenience and innovation.

Eco-consciousness is on the rise, and the air fryer industry is responding with more energy-efficient models. As consumers become more environmentally aware, they are looking for appliances that not only save them money on energy bills but also have a smaller carbon footprint. Manufacturers are responding by developing air fryers that consume less power without compromising on performance.

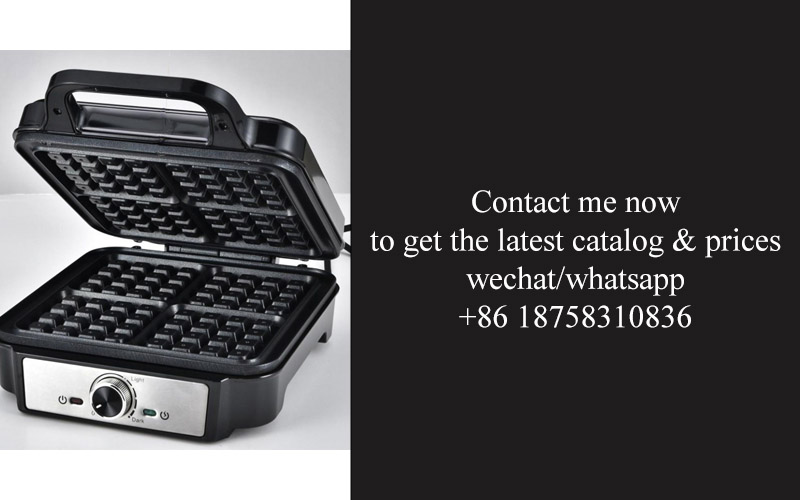

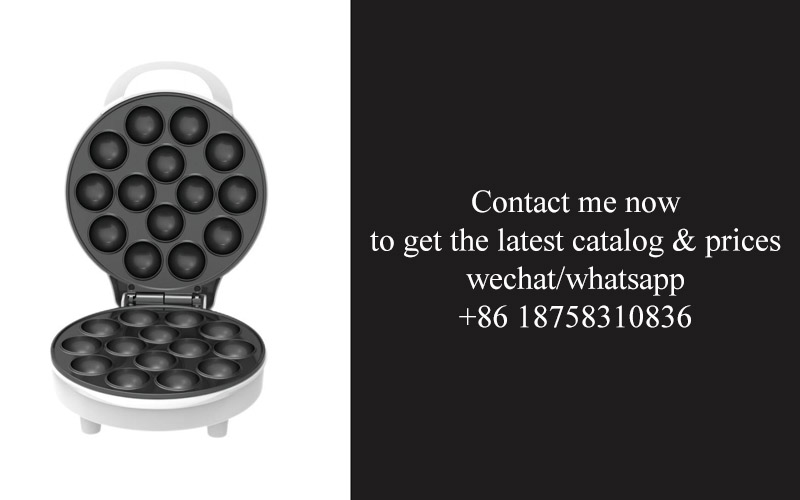

The rise of health-focused cooking has also led to an increase in specialty air fryers. These include models designed for specific types of cooking, such as air fryers with dehydrator capabilities or those optimized for crispy French fries. This niche targeting allows manufacturers to cater to specific consumer needs and preferences.

Globalization has played a role in shaping the air fryer market as well. As these appliances gain popularity in one region, they spread to others, often with localized adaptations to cater to cultural preferences. For example, certain models may come with specific features that make them more suitable for Asian or Mediterranean cooking styles.

Health trends are not limited to air fryers themselves; they are also influencing the types of ingredients and cooking methods associated with them. There’s a growing interest in organic and non-GMO ingredients, which is reflected in the availability of air fryer accessories and recipe guides that emphasize these options.

The market is also seeing a trend towards healthier cooking oils, with some air fryer models now coming with oil dispensers that automatically add the right amount of cooking oil. This not only simplifies the cooking process but also ensures that users are using the healthiest oil options available.

As the air fryer market continues to grow, manufacturers are focusing on sustainability. This includes the use of recycled materials in the production of air fryers and the development of appliances that can be easily recycled at the end of their life cycle. The emphasis on sustainability is not only a response to consumer demands but also a strategic move to differentiate products in a crowded market.

Lastly, the rise of social media and influencer marketing has had a profound impact on the air fryer market. Consumers are more likely to be influenced by online reviews and demonstrations of air fryer capabilities, leading to a viral spread of popular models. This digital marketing trend is likely to continue as more consumers turn to online platforms for product recommendations and inspiration.

The shift towards automated air fryer assembly lines has brought about a noticeable change in the environmental footprint of the kitchen appliance industry. This transformation is not just a reflection of technological advancement but also a critical step towards sustainability. Here’s how it’s making a difference:

Energy Efficiency:Automated assembly lines are designed with energy conservation in mind. Advanced machinery and robotics are more efficient than traditional methods, leading to reduced energy consumption. This is particularly significant in the manufacturing process, where high-energy equipment is often used.

Waste Reduction:Automation minimizes waste in several ways. The precision of automated systems ensures that materials are used more effectively, reducing excess and scrap. Additionally, the reduction in manual handling cuts down on packaging waste, as products are less likely to be damaged or require additional protective materials.

Water Conservation:Automated assembly lines often incorporate water-saving technologies. For instance, automated cleaning systems use less water than manual cleaning processes, and precision in assembly reduces the need for water-intensive operations like washing hands or cleaning tools repeatedly.

Sustainable Materials:With the increasing emphasis on sustainability, manufacturers are integrating eco-friendly materials into the assembly process. This includes using biodegradable materials for packaging and components that are recyclable or made from recycled materials.

Lower Carbon Footprint:By reducing energy consumption and waste, the automated assembly lines contribute to a lower overall carbon footprint. This is crucial in the context of climate change, as the appliance industry is a significant contributor to greenhouse gas emissions.

Eco-friendly Production:The entire production process is optimized for environmental impact. From the sourcing of raw materials to the final product disposal, manufacturers are adopting practices that reduce environmental harm. This includes responsible sourcing of metals and plastics, which are often used in the construction of air fryers.

Transportation and Distribution:The efficiency of automated assembly lines also translates to more eco-friendly transportation and distribution. By producing air fryers more quickly and with less waste, manufacturers can reduce the number of trucks needed for shipping, thus cutting down on fuel consumption and emissions.

Recycling and Disposal:The end of life for an air fryer is now being considered with greater care. Manufacturers are investing in recycling programs and developing products that are easier to disassemble and recycle. This approach ensures that the materials used in air fryers can be repurposed, extending their lifecycle and reducing the environmental impact.

Regulatory Compliance:As environmental regulations become more stringent, the adoption of automated assembly lines is a strategic move for manufacturers. By integrating sustainable practices, companies can comply with these regulations while also appealing to consumers who are increasingly environmentally conscious.

Consumer Influence:Consumers today are more aware of the environmental impact of their purchases. The shift towards automated air fryer assembly lines is a direct response to this consumer demand for more sustainable products. As a result, the industry is under pressure to continue innovating and improving its environmental performance.

Long-term Sustainability:The impact on the environment is not just a short-term gain; it’s about long-term sustainability. By investing in automated assembly lines and sustainable practices, the kitchen appliance industry is paving the way for a more sustainable future, where environmental considerations are at the core of manufacturing processes.

Global Trends:The trends towards automated assembly lines and environmental sustainability are not isolated to any one region. They are global trends that reflect a broader shift in how industries operate. This global convergence is leading to a more standardized approach to manufacturing that is both efficient and environmentally responsible.

Closing the Loop:The ultimate goal is to close the loop on product life cycles. This means designing products that can be easily recycled or repurposed at the end of their life. Automated assembly lines are a critical component in achieving this goal by enabling the creation of more modular and recyclable products.

Educational and Advocacy Efforts:As the industry evolves, educational and advocacy efforts are becoming more prevalent. Manufacturers are working to educate consumers about the environmental benefits of their products and to encourage recycling and proper disposal practices.

The Future of Sustainability:The impact of automated air fryer assembly lines on the environment is just the beginning. As technology continues to advance, we can expect to see even more innovative and sustainable solutions emerge in the kitchen appliance industry. The future looks promising, with a focus on reducing environmental impact at every stage of the product lifecycle.

In the world of kitchen appliances, a few companies have stood out with their successful implementation of automated air fryer assembly lines. Let’s delve into their journeys and the remarkable outcomes they’ve achieved.

These case studies highlight the transformative power of automated air fryer assembly lines. From increased efficiency and reduced waste to enhanced quality and market expansion, these companies have shown that automation can be a catalyst for growth and success in the kitchen appliance industry.

The adoption of automated systems in the assembly line for air fryers has indeed brought about a wave of advancements. However, like any significant shift in technology and manufacturing, it also comes with its set of challenges and considerations. Navigating these hurdles is crucial for companies looking to implement or improve their automated air fryer assembly lines.

By carefully addressing these challenges and considerations, companies can leverage the benefits of automated air fryer assembly lines while ensuring a smooth transition and sustainable growth in the market.

In the ever-evolving landscape of technology and consumer preferences, the future of the automated air fryer assembly line is a beacon of innovation and efficiency. From advancements in robotics to the integration of smart systems, the industry is poised for significant transformations. Here’s a glimpse into what lies ahead:

The rise of Industry 4.0 is not just a buzzword; it’s a reality shaping the future of manufacturing. As automation continues to permeate various sectors, the air fryer assembly line is no exception. We’re talking about a future where interconnected devices and systems work in harmony to optimize production, ensuring that every aspect of the manufacturing process is streamlined and efficient.

Imagine a scenario where predictive maintenance becomes the norm. Sensors embedded within the assembly line equipment can predict when a part might fail, allowing for preemptive repairs or replacements. This not only minimizes downtime but also ensures that the quality of the air fryers remains top-notch.

Energy efficiency is another key area where we’re likely to see advancements. With the growing concern over climate change and the push for sustainable practices, manufacturers are under pressure to reduce their carbon footprint. Innovations in energy-saving technologies, such as more efficient motors and smart heating systems, will become standard in the assembly line, making the production process greener and more cost-effective.

The role of artificial intelligence (AI) is set to expand significantly. AI algorithms can analyze vast amounts of data to improve the assembly process. From optimizing production schedules to fine-tuning the performance of individual machines, AI will play a crucial part in ensuring that the assembly line operates at peak efficiency.

As for the workforce, the future will likely see a shift in roles. While there will still be a need for skilled technicians and engineers, the emphasis may shift towards those who can manage and maintain the complex systems. This could lead to a new wave of training and education in the field of automation and robotics.

The rise of modular assembly lines is also a trend to watch. These lines can be easily reconfigured to accommodate changes in product design or production volume. This flexibility is particularly important in a market as dynamic as kitchen appliances, where innovation is key to staying competitive.

In terms of product development, we can expect to see a surge in customization. The assembly line of the future may be capable of producing air fryers with a wide range of features and functionalities, tailored to the specific needs of different consumer segments. This could include everything from adjustable cooking temperatures to smart connectivity with kitchen management systems.

Moreover, the integration of virtual reality (VR) and augmented reality (AR) could revolutionize the design and testing phases of the air fryer assembly process. Designers could use VR to visualize products in a virtual environment, while AR could provide real-time assistance to technicians on the assembly line.

In the realm of materials, there’s a growing movement towards sustainability. Biodegradable plastics and recycled materials are becoming more common, not just in the finished product but also in the components used in the assembly line itself. This shift reflects a broader industry trend towards environmental responsibility.

As we look ahead, it’s clear that the future of the automated air fryer assembly line is not just about producing more units faster. It’s about creating a more intelligent, adaptable, and sustainable manufacturing process. The companies that embrace these changes and lead the charge in innovation will be the ones that shape the kitchen appliance industry for years to come.

In reflecting on the journey of the automated air fryer assembly line, it’s clear that the industry has reached a significant milestone. As we stand at this juncture, it’s important to acknowledge the transformative impact it has had on the kitchen appliance market. The shift from manual to automated production has not only streamlined the manufacturing process but has also opened up new avenues for innovation and sustainability. Let’s ponder over the implications of this technological leap and its potential to shape the future of kitchen appliances.

The automation of the air fryer assembly line has brought about a myriad of benefits, from enhancing productivity to reducing waste. As manufacturers continue to embrace advanced technologies, the possibilities for further advancements seem limitless. The integration of robotics, AI, and IoT has not only improved the efficiency of the assembly process but has also paved the way for a more connected and intelligent kitchen ecosystem.

From a consumer’s perspective, the convenience and health benefits offered by air fryers have been well-received. However, the journey to this point has not been without its challenges. Adapting to new technologies, ensuring workforce skills alignment, and maintaining product quality while driving down costs have been key considerations for manufacturers. As we look ahead, it’s essential to consider the potential risks and rewards that lie in store for the industry.

In the realm of sustainability, the impact of the automated air fryer assembly line cannot be overstated. By reducing energy consumption, minimizing waste, and optimizing resource use, these assembly lines are contributing to a greener, more eco-friendly manufacturing landscape. This shift towards sustainability is not just a trend but a necessity in an increasingly environmentally conscious world.

Several companies have already capitalized on the benefits of automated assembly lines and have seen remarkable success. From small startups to established giants, these case studies offer valuable insights into the transformative power of automation in the kitchen appliance sector. The stories of these companies serve as a testament to the potential for growth and innovation that lies ahead.

As we delve into the challenges and considerations facing the industry, it’s crucial to recognize that the path to full-scale automation is not without its obstacles. For instance, the initial investment in new technology can be substantial, and the transition period for workforce training and adaptation requires careful planning. Moreover, ensuring compliance with safety standards and maintaining the highest quality control measures are ongoing concerns.

Looking ahead, the future of the air fryer assembly line is bright. The continuous evolution of technology promises to bring even more sophisticated solutions to the table. With the rise of smart kitchen appliances and the increasing demand for healthier cooking options, the market for air fryers is expected to grow exponentially. Innovations such as modular assembly lines, which can be easily reconfigured for different product lines, will play a pivotal role in meeting these demands.

In conclusion, the automated air fryer assembly line has been a game-changer for the kitchen appliance industry. It has not only revolutionized the way we produce these devices but has also set the stage for a future where technology, sustainability, and consumer needs are in perfect harmony. As we continue to innovate and adapt, the potential for the air fryer and other kitchen appliances to enhance our lives in meaningful ways is boundless. The journey of the automated air fryer assembly line is a testament to human ingenuity and the relentless pursuit of progress.