Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

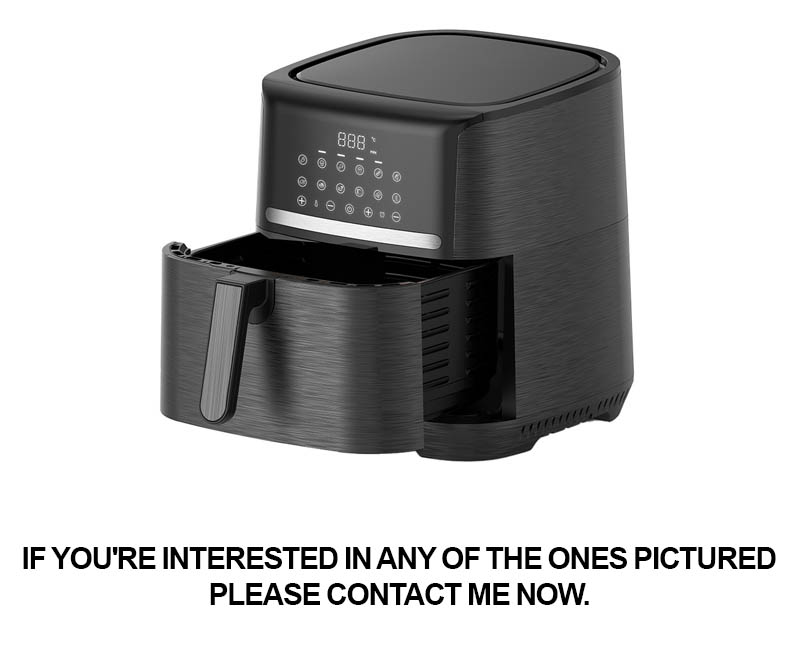

In a world increasingly conscious of health and wellness, the air fryer has emerged not just as a kitchen gadget but as a symbol of culinary innovation. This compact appliance has revolutionized the way we cook, offering a healthier alternative to traditional frying methods. As we delve into the air fryer industry, we discover a landscape rich with technological advancements, strategic partnerships, and a relentless pursuit of perfection. Join us as we explore the intricate details of air fryer manufacturing, from the mold-making process to the future trends shaping this dynamic sector.

The Air Fryer Phenomenon: A Game-Changer in Healthy Cooking

As the culinary landscape evolves, there’s been a remarkable shift towards healthier cooking methods. At the forefront of this revolution is the air fryer, a kitchen gadget that has taken the world by storm. Once a niche product, the air fryer has now become a staple in many modern kitchens, offering a healthier alternative to traditional deep-frying.

This surge in popularity can be attributed to several factors. Firstly, health-conscious consumers are increasingly looking for ways to reduce their intake of unhealthy fats and calories. The air fryer’s ability to cook food with minimal oil has made it an appealing choice for those following low-fat diets. Secondly, the convenience of the air fryer is undeniable. It’s compact, easy to use, and can cook a variety of dishes in a fraction of the time it takes to deep-fry.

Moreover, the air fryer has also captured the interest of chefs and home cooks alike for its versatility. It can be used to prepare everything from crispy French fries to tender chicken wings, without the guilt of deep-frying. This has not only expanded the culinary possibilities but has also sparked a wave of creative recipes and cooking techniques.

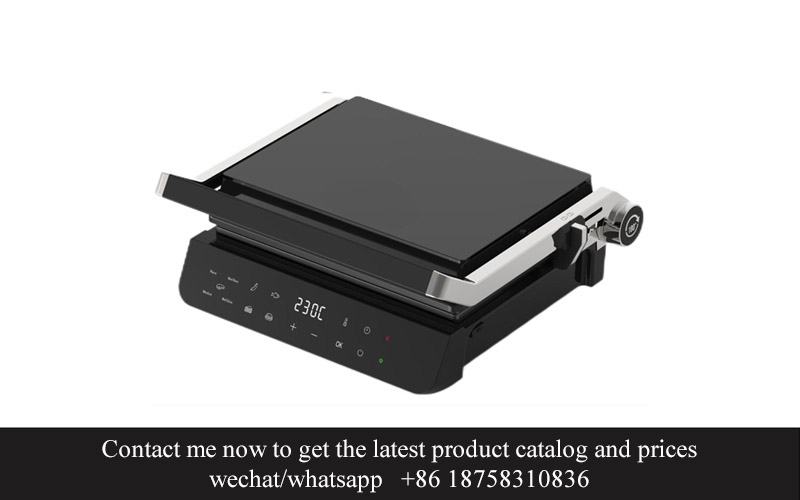

The air fryer’s design is another key factor in its popularity. Many models now come with features like adjustable temperature controls, allowing users to tailor the cooking process to their preference. The inclusion of digital timers and pre-programmed settings has made it even easier for the average cook to achieve restaurant-quality results at home.

But the story of the air fryer’s rise doesn’t end with its convenience and health benefits. It’s also a testament to the power of innovation in the kitchen. Companies have been quick to adapt and improve upon the original concept, introducing new features that enhance the cooking experience. From non-stick surfaces that make cleanup a breeze to air fryer ovens that can bake, roast, and grill, the technology has evolved to meet the demands of today’s consumers.

One of the most significant developments in the air fryer market is the rise of OEM (Original Equipment Manufacturer) services. These services allow smaller brands and even individual entrepreneurs to produce their own line of air fryers without the need for extensive R&D or manufacturing capabilities. This has democratized the market, making it possible for a wider range of companies to offer air fryers to consumers.

The mold making service plays a crucial role in this process. By creating custom molds for air fryer components, manufacturers can ensure that each piece fits perfectly and functions as intended. This precision is essential for the air fryer’s performance and durability, which are two factors that consumers value highly.

The air fryer market is also being driven by the availability of a wide range of accessories and attachments. From air fryer baskets to dehydrator racks, these additions expand the capabilities of the device, allowing users to experiment with new recipes and cooking methods.

In conclusion, the air fryer phenomenon is a clear indicator of the ongoing shift towards healthier, more convenient cooking methods. As the market continues to grow and evolve, we can expect to see even more innovative designs and features that cater to the diverse needs of consumers. The air fryer has truly become a game-changer in the world of cooking, and its journey is far from over.

The OEM air fryer market has emerged as a significant segment within the kitchen appliances industry, driven by a growing consumer demand for healthier cooking options. As more people seek to reduce oil consumption and adopt healthier lifestyles, the popularity of air fryers has surged. Here’s a closer look at what makes this market so dynamic.

Consumer Trends and Health AwarenessConsumers today are more health-conscious than ever before, and this shift has directly influenced the air fryer market. The desire to minimize the intake of unhealthy fats has led to a surge in the sales of air fryers, which use a fraction of the oil compared to traditional deep fryers. This trend is particularly strong in urban areas where time-poor, health-aware consumers are looking for quick and nutritious meal solutions.

Globalization and Market ExpansionThe OEM air fryer market is not confined to any single region; it’s a global phenomenon. As the technology becomes more affordable and the health benefits more widely recognized, the market is expanding rapidly across various countries. This globalization has led to a diverse range of OEM partners, each with their own unique needs and requirements.

Competition and Market SaturationWith the rise in demand, the market has become increasingly competitive. Numerous manufacturers are now offering their own versions of air fryers, leading to a market that’s becoming more saturated. This competition has spurred innovation, but it has also made it crucial for OEMs to differentiate their products through unique features, design, and quality.

Customization and BrandingOEM air fryers offer a unique opportunity for brands to customize their products to fit their brand identity and customer expectations. From sleek designs to advanced functionalities, the ability to tailor the product to a specific market or brand is a key driver in the OEM market. This customization can range from minor design adjustments to integrating proprietary technologies.

Supply Chain and Production EfficiencyThe OEM air fryer market requires a robust supply chain to ensure that products are produced efficiently and meet the high standards set by global customers. This involves managing relationships with component suppliers, ensuring quality control, and optimizing production processes. Efficiency in the supply chain is vital for maintaining competitive pricing and quick delivery times.

Regulatory Compliance and Safety StandardsAs with all kitchen appliances, air fryers must comply with various safety and regulatory standards. This is particularly important for OEMs that export to different countries with different regulations. Ensuring that products meet these standards is not only a legal requirement but also a trust-building factor with consumers.

Product Lifecycle ManagementUnderstanding the lifecycle of an air fryer is crucial for OEMs. This includes market research to identify trends, product development to create innovative solutions, production to maintain quality, and after-sales service to provide customer support. Managing the entire lifecycle is essential for maintaining a strong market position and customer satisfaction.

Sustainability and Eco-Friendly PracticesWith the increasing focus on sustainability, OEMs in the air fryer market are looking for ways to reduce their environmental impact. This can involve using eco-friendly materials, reducing energy consumption during production, and designing products that are durable and recyclable. Sustainability is not just a trend; it’s becoming a key differentiator in the market.

Technology Integration and Smart FeaturesThe integration of smart technology into air fryers is another area where OEMs are focusing. Features like remote control, smart connectivity, and pre-programmed recipes are becoming standard. This technology-driven approach is appealing to tech-savvy consumers who want convenience and control over their cooking experience.

Market Analysis and Strategic PartnershipsTo thrive in the OEM air fryer market, it’s essential to conduct thorough market analysis. This includes understanding consumer behavior, identifying emerging markets, and forming strategic partnerships with suppliers and distributors. These partnerships can provide valuable insights and help OEMs stay ahead of the curve in a rapidly evolving market.

In conclusion, the OEM air fryer market is a complex and multifaceted industry that requires a deep understanding of consumer trends, health awareness, and global market dynamics. By focusing on customization, efficiency, compliance, and innovation, OEMs can position themselves as leaders in the market and meet the demands of a health-conscious consumer base.

Mold making service is a critical component in the production of air fryers, serving as the backbone for the manufacturing process. It’s the unsung hero that shapes the design and functionality of these kitchen appliances. Here’s a deeper look into why this service is so vital.

The precision of mold making directly impacts the quality of the air fryer. Each mold is meticulously crafted to ensure that the plastic or metal components fit together seamlessly. The tighter the tolerances, the more durable and reliable the final product will be. Even the smallest inconsistencies in the mold can lead to air fryers that don’t function as intended, which can be costly for both the manufacturer and the consumer.

Customization is key in the OEM air fryer market. Brands looking to differentiate themselves from the competition rely on mold making services to create unique shapes, sizes, and features. Whether it’s a sleek, modern design or a compact, space-saving model, the molds are the blueprint for these innovations. Without this service, the industry would lack the variety and innovation that consumers have come to expect.

Material selection is another area where mold making plays a crucial role. The choice of plastic or metal for the air fryer components can affect everything from the weight of the appliance to its heat resistance. Mold makers must understand the properties of different materials to create molds that can produce parts that meet specific performance criteria. This expertise ensures that the air fryer not only looks great but also performs effectively under various cooking conditions.

The complexity of air fryer molds can vary greatly. Simple molds might consist of a few basic parts, while high-end models with multiple functions can require intricate molds with multiple cavities and complex geometries. Each mold is a testament to the craftsmanship and technical skill of the mold makers. The better the mold, the more efficiently the production line can operate, reducing costs and increasing output.

Mold maintenance is a crucial aspect of the mold making service. Over time, molds can become worn or damaged, leading to inconsistencies in the parts they produce. Regular maintenance and repair by skilled technicians are essential to keep the production line running smoothly. This ongoing attention to the molds ensures that the quality of the air fryers remains consistent throughout their production lifecycle.

The cost-effectiveness of mold making cannot be overstated. While the initial investment in a high-quality mold can be significant, it pays off in the long run. A well-made mold can produce thousands or even millions of parts without significant wear, reducing the need for frequent replacements and thus lowering overall production costs. This efficiency is a key factor in the competitive OEM market.

Innovation in mold making is constantly evolving. Advanced technologies such as 3D printing and CNC machining are revolutionizing the way molds are designed and produced. These advancements allow for more complex designs and shorter lead times, making it easier for OEMs to bring new products to market quickly. The mold making service must stay abreast of these technological changes to ensure that they can offer the most efficient and cost-effective solutions.

Quality control is integral to the mold making service. Molds must be tested to ensure they produce parts that meet the required specifications. This involves rigorous testing for fit, form, and function. Any defects in the mold can lead to defects in the air fryer, so thorough quality checks are necessary. This attention to detail ensures that the final product is of the highest quality.

Lastly, the environmental impact of mold making cannot be ignored. As sustainability becomes a growing concern, mold makers are increasingly using materials and processes that are more eco-friendly. This includes the development of molds that can be recycled or are made from recycled materials. The OEM air fryer market is taking notice of these green initiatives, as they align with the values of many consumers.

In summary, mold making service is pivotal in the production of air fryers, influencing everything from design and functionality to cost and environmental impact. Its importance cannot be overstated, as it is the foundation upon which the success of the OEM air fryer market is built.

In the ever-evolving world of kitchen appliances, the air fryer has emerged not just as a trend but as a staple in modern households. The advancements in its design and functionality have been nothing short of revolutionary. Let’s delve into the innovations that have made the air fryer a must-have in today’s kitchens.

The air fryer’s initial design was straightforward, a simple basket that cooked food by circulating hot air around it. But as consumer demands grew, so did the creativity in design. One significant innovation is the introduction of multi-layer baskets, allowing for a variety of foods to be cooked simultaneously without the risk of them sticking together or becoming overcooked.

One of the most notable advancements is the inclusion of adjustable temperature controls. Early models often had a fixed temperature setting, which limited the types of food that could be cooked. Today’s air fryers come with precise temperature control, enabling users to achieve the perfect crispness on the outside while keeping the inside tender and juicy.

Another innovation that has taken the air fryer market by storm is the inclusion of smart technology. Many modern air fryers are now equipped with Wi-Fi capabilities, allowing users to control their appliances remotely through their smartphones. This feature not only adds convenience but also opens up a world of possibilities, such as preheating the air fryer before you arrive home.

The design of the cooking basket itself has seen considerable evolution. Some models now feature non-stick coatings that are more durable than traditional non-stick surfaces, making cleaning easier and more efficient. Additionally, the shape of the basket has been refined to optimize air flow, ensuring that food cooks evenly and doesn’t get stuck in corners.

Functionality has expanded beyond the basic air frying process. Many air fryers now offer a range of cooking modes, including roasting, baking, and dehydrating. This versatility means that users can enjoy a wider variety of recipes without the need for multiple appliances. The ability to air fry and bake simultaneously is particularly popular, as it saves time and energy.

One of the most innovative features in recent years is the inclusion of a built-in timer. This allows users to set the exact cooking time they need, and the air fryer will automatically shut off when the time is up. Some models even have a safety feature that ensures the unit remains cool to the touch after cooking, reducing the risk of burns.

In terms of aesthetics, air fryers have also seen a design overhaul. No longer are they just utilitarian kitchen gadgets; they come in a variety of colors and styles, fitting seamlessly into modern kitchen decor. The sleeker, more compact designs also make them easier to store, a crucial factor for many consumers with limited kitchen space.

The integration of eco-friendly materials is another area where innovation has made a significant impact. Many air fryer manufacturers are now using sustainable materials for their appliances, not only reducing their environmental footprint but also appealing to environmentally conscious consumers.

Finally, there’s the rise of air fryer accessories. From additional baskets to temperature probes and even air fryer-specific recipe books, the market has expanded to cater to the needs of enthusiasts who want to take their air frying to the next level.

The air fryer’s journey from a simple kitchen gadget to a versatile, multi-functional appliance is a testament to the power of innovation. As technology continues to advance, we can expect even more creative designs and functionalities to hit the market, making air frying an even more appealing cooking method for years to come.

In the fast-paced world of product development, the role of data and trend analysis cannot be overstated. These elements are the backbone of creating innovative and consumer-centric products, especially in the competitive and ever-evolving kitchen appliance industry. Let’s delve into how this vital process shapes the future of air fryer design and production.

Consumer Insights and Market ResearchUnderstanding the needs and preferences of consumers is paramount. Data gathered from market research provides insights into what customers are looking for in their air fryers. This could range from energy efficiency to convenience features, and from health benefits to design aesthetics. By analyzing this data, manufacturers can identify gaps in the market and tailor their products to meet unmet consumer demands.

Trend Spotting in Technology and LifestyleThe world is changing rapidly, and so are consumer lifestyles. Trends in technology, such as the rise of smart home devices, influence the way appliances are designed. Similarly, shifts in lifestyle, like an increasing focus on health and wellness, can drive the need for healthier cooking methods. Trend analysis helps in predicting these changes and integrating them into the product development process.

Predictive Analytics and ForecastingUsing advanced data analytics, companies can forecast future market demands and consumer behavior. This predictive approach allows for proactive product development rather than reactive. By knowing what’s coming, manufacturers can stay ahead of the curve and develop air fryers that not only cater to current needs but also anticipate future ones.

Performance Metrics and Quality ControlData plays a crucial role in ensuring the quality and performance of air fryers. Through rigorous testing and performance metrics, developers can identify the strengths and weaknesses of their products. This data-driven approach helps in optimizing designs, enhancing durability, and ensuring safety standards are met.

User Experience and FeedbackThe ultimate goal of any product is to provide a seamless user experience. By analyzing user feedback, manufacturers can refine their products to better align with user expectations. This could involve adjusting control panels for easier navigation or improving the cooking capacity to handle larger batches of food.

Globalization and LocalizationTrend analysis is not limited to domestic markets; it’s a global endeavor. Companies need to consider cultural differences and local preferences when designing air fryers for international markets. Data on global consumption patterns and regional tastes can guide the customization of products to cater to diverse consumer bases.

Cost-Benefit Analysis and EfficiencyEfficiency in production is as important as innovation in design. Data analysis helps in conducting cost-benefit analyses, ensuring that new features are not only beneficial to the user but also economically viable for the manufacturer. This balance between cost-effectiveness and technological advancement is key to successful product development.

Sustainability and Environmental ImpactAs environmental concerns grow, data and trend analysis are instrumental in guiding the development of eco-friendly air fryers. By assessing the environmental impact of materials and manufacturing processes, companies can make sustainable choices that resonate with environmentally conscious consumers.

In conclusion, the role of data and trend analysis in product development is multifaceted. It drives innovation, informs strategic decisions, and ensures that the end product is not only cutting-edge but also meets the evolving needs and preferences of the global consumer base. By harnessing the power of data, manufacturers can create air fryers that stand out in the market and contribute to a healthier, more sustainable future.

In the world of air fryer production, the quality of the product is paramount. The mold making service plays a crucial role in ensuring that the air fryers are not only functional but also durable and aesthetically pleasing. Here’s how this service enhances the overall quality of air fryers:

The precision of the mold is essential in the manufacturing process. A well-crafted mold ensures that every air fryer produced is of the same high standard. Molds are designed with intricate details that can affect the air fryer’s performance, such as the shape of the basket, the size of the cooking surface, and the placement of the heating elements. The accuracy of these molds directly impacts the efficiency of the air fryer’s operation.

The materials used in mold making are of the utmost importance. High-quality materials like stainless steel or aluminum are chosen for their durability and heat resistance. These materials are not only strong enough to withstand the manufacturing process but also ensure that the air fryer can handle the high temperatures required for cooking without deforming or losing its structural integrity.

The complexity of the mold design can dictate the quality of the air fryer. Advanced molds can create intricate shapes and patterns that not only enhance the product’s appearance but also improve its functionality. For example, a mold that allows for the creation of a non-stick surface coating ensures that food releases easily, making the air fryer more user-friendly and easier to clean.

The consistency of the mold making process is key to maintaining quality. A reliable mold making service will produce molds that are consistent in their dimensions and tolerances. This consistency translates to a consistent product, reducing the likelihood of defects or issues that could affect the user experience.

Customization is another aspect where mold making service shines. Many air fryer manufacturers offer a range of products with different features and capacities. The ability to create custom molds allows for the production of unique designs that cater to specific market demands or branding requirements. This level of customization can significantly differentiate one air fryer from another in terms of quality and appeal.

The longevity of the mold itself is a reflection of the air fryer’s quality. A well-maintained mold can be used for thousands of cycles without losing its shape or precision. This means that the air fryers produced will consistently meet the manufacturer’s quality standards, even as production volumes increase over time.

Quality control during the mold making process is critical. Any imperfections in the mold can lead to inconsistencies in the air fryer’s design, which in turn can cause performance issues. A meticulous inspection process ensures that the molds are free from defects and that they meet the required specifications.

Innovation in mold making technology has also had a positive impact on air fryer quality. Advances such as CNC (Computer Numerical Control) machining have allowed for the creation of molds with greater complexity and precision. This technological advancement means that air fryers can now be produced with features that were not possible before, such as more even heat distribution and improved cooking efficiency.

The environmental considerations of mold making are also important. Sustainable practices in mold manufacturing can lead to the creation of more eco-friendly air fryers. By using recyclable materials and reducing waste during the mold making process, manufacturers can contribute to a greener product lifecycle.

Finally, the collaboration between mold makers and air fryer manufacturers is vital. Open communication and feedback loops ensure that the mold making service aligns with the manufacturer’s vision for product quality. This partnership helps in addressing any issues promptly and in developing molds that are optimized for the best possible air fryer performance.

In summary, the mold making service is a cornerstone of air fryer quality. From the precision of the mold design to the materials used and the environmental impact, every aspect of mold making plays a role in determining the quality and success of the final air fryer product.

Navigating the world of air fryer manufacturing, selecting a reputable OEM (Original Equipment Manufacturer) partner can make all the difference in the quality and success of your product. Here are several key benefits that come with choosing a top-tier OEM air fryer manufacturer:

Precision Engineering and Cutting-Edge TechnologyA reputable OEM manufacturer invests heavily in state-of-the-art equipment and skilled technicians. This ensures that every air fryer they produce is crafted with precision, using the latest engineering techniques. From the design phase to the final assembly, these manufacturers prioritize quality and innovation, resulting in air fryers that not only perform exceptionally well but also stand out in the competitive market.

Customization and Tailored SolutionsOne of the advantages of working with a reputable OEM is the ability to customize your air fryer. Whether you need a specific size, unique features, or branding, a reliable manufacturer can work closely with you to create a product that aligns perfectly with your brand identity and customer expectations. This level of customization can set your product apart from the competition and cater to niche markets more effectively.

Strict Quality ControlQuality is non-negotiable in the air fryer industry. A reputable OEM manufacturer maintains rigorous quality control processes throughout the production cycle. From sourcing high-quality materials to conducting thorough inspections at each stage of assembly, these manufacturers ensure that each air fryer meets the highest standards of quality and safety. This commitment to quality can build trust with consumers and enhance your brand’s reputation.

Efficient Production and Shorter Lead TimesAn experienced OEM manufacturer has streamlined production processes that allow for efficient production without compromising quality. This efficiency can translate into shorter lead times for your orders, meaning you can get your products to market faster. This agility is crucial in a fast-paced industry where staying ahead of trends and meeting customer demands is essential.

Comprehensive Support and After-Sales ServiceChoosing a reputable OEM means gaining access to a team that is dedicated to your success. These manufacturers often provide comprehensive support, from initial design consultation to post-production assistance. They may offer training programs for your staff, marketing materials, and even after-sales service to help you maintain customer satisfaction and brand loyalty.

Access to Advanced Research and DevelopmentTop-tier OEM manufacturers are often at the forefront of technological advancements. By working with them, you gain access to their R&D capabilities, which can be instrumental in staying ahead of the curve. Whether it’s integrating new cooking technologies, improving energy efficiency, or creating innovative features, a reputable OEM can help you push the boundaries of what’s possible in air fryer design.

Competitive Pricing without Compromising QualityWhile cost is a significant factor in choosing an OEM manufacturer, a reputable one can offer competitive pricing without skimping on quality. They achieve this by optimizing their production processes, leveraging economies of scale, and sourcing materials efficiently. This allows you to offer your customers a high-quality air fryer at a price point that remains attractive.

Global Reach and Distribution SupportA reputable OEM manufacturer typically has a global reach, which means they can assist with distribution and logistics. They can help you navigate international markets, understand local regulations, and ensure that your air fryers meet the specific requirements of different regions. This support can be invaluable for expanding your business overseas.

Brand Consistency and ImageBy choosing a reputable OEM, you ensure that your brand image remains consistent across all your products. From the design and functionality to the packaging and branding, a trusted manufacturer will help maintain the integrity of your brand. This consistency can build trust and recognition among consumers, leading to increased brand loyalty.

Long-Term Partnerships and ScalabilityA reputable OEM manufacturer is interested in building long-term relationships with their clients. They understand that scalability is key to growth and can adapt to changes in your business needs. Whether you’re looking to increase production, launch a new line of products, or enter new markets, a reliable OEM partner can grow with you, providing the support and expertise you need to succeed.

In the world of kitchen appliances, air fryers have soared in popularity, becoming a staple in modern households. The key to their success lies not just in their convenience but in the quality of their design and manufacturing. Case studies of air fryer products that have capitalized on mold making services illustrate the profound impact these services can have on the final product.

One such case study involves a leading OEM air fryer manufacturer that revolutionized the market with a unique, eco-friendly air fryer design. By utilizing advanced mold making techniques, the company was able to create a fryer with an aerodynamic shape that optimized air flow, reducing cooking times and energy consumption. The precision of the molds allowed for a sleek, integrated handle that didn’t compromise the structural integrity of the appliance.

Another example is a mid-range brand that sought to differentiate itself with a customizable air fryer line. By working closely with mold makers, they were able to develop a range of fryers with interchangeable parts. This innovative approach meant customers could tailor their fryer to their specific cooking needs, from a compact model for solo chefs to a larger capacity fryer for families. The molds were so precise that the parts fit seamlessly, ensuring a consistent performance and look across all models.

A notable success story comes from a company that focused on health-conscious consumers with their line of air fryers designed for gluten-free and low-carb diets. The mold making service played a crucial role in creating non-stick surfaces that were both durable and safe to use at high temperatures. The molds were crafted with intricate details to ensure the non-stick coating was applied evenly, reducing the risk of food sticking and providing a longer lifespan for the fryer.

In yet another case, a budget-friendly air fryer manufacturer used mold making services to produce fryers with innovative features that were previously only available in high-end models. The molds allowed for the integration of features like digital displays, programmable cooking modes, and easy-to-clean baskets. The consistency in the molds’ design meant that these features were reliable and functional across all price points, making the product more accessible to a wider market.

One cannot overlook the importance of aesthetics in kitchen appliances. A company that focused on design-oriented consumers turned to mold making to create a line of air fryers with unique, modern aesthetics. The molds were designed to produce fryers with sleek lines, minimalist controls, and a color palette that complemented various kitchen decors. This attention to detail was only possible due to the precision and consistency that mold making services provide.

In a competitive market, one brand stood out by offering a range of air fryers with unique cooking capabilities. The mold making service was instrumental in producing fryers that could handle both air frying and dehydrating functions. The molds had to accommodate complex shapes and multiple components, ensuring that the fryers were not only versatile but also visually appealing. The result was a product that not only met customer needs but also set new standards for the industry.

These case studies demonstrate the multifaceted benefits of mold making services in the production of air fryers. From enhancing the functionality and efficiency of the appliances to ensuring they stand out in terms of design and durability, mold making is a critical component in bringing successful air fryer products to market. The ability to create intricate molds that are precise and consistent is what sets apart those manufacturers who deliver the highest quality products from those who merely produce appliances.

In the ever-evolving landscape of kitchen appliances, air fryers have surged in popularity, becoming a staple in many homes. As the demand for healthier cooking options grows, understanding the future trends and challenges in the air fryer industry is crucial for both manufacturers and consumers alike. From advancements in technology to the impact of sustainability, here’s a glimpse into what the future holds.

The integration of smart technology in air fryers is on the rise, with features like touchscreens, Bluetooth connectivity, and app integration becoming more common. These innovations not only enhance the user experience but also allow for personalized cooking settings and remote monitoring, which can be particularly appealing to tech-savvy consumers.

Energy efficiency is a major concern for many, and the air fryer industry is no exception. As consumers become more environmentally conscious, manufacturers are under pressure to develop air fryers that consume less power without compromising on performance. This could lead to the adoption of new materials and designs that are more energy-efficient.

The rise of the health-conscious consumer has also influenced the development of air fryers. There’s a growing trend towards air fryers that can handle a wider variety of cooking techniques, from grilling to roasting, allowing for a more versatile appliance that can mimic the flavors of traditional frying without the added fat.

Sustainability is becoming a key factor in product development. With the increasing awareness of the environmental impact of manufacturing and waste, air fryer manufacturers are looking for ways to reduce their carbon footprint. This could involve using recycled materials, implementing more eco-friendly manufacturing processes, and designing products that are easier to recycle at the end of their lifecycle.

Customization is another trend that’s gaining traction. Consumers are looking for appliances that can be tailored to their specific needs, whether that’s through adjustable settings, modular components, or even personalized branding. This shift towards customization requires manufacturers to invest in more flexible production lines and to understand the diverse preferences of their global customer base.

Safety remains a top priority in the air fryer industry. As technology advances, ensuring that these appliances are safe to use is paramount. This includes not just the physical safety of the user but also the longevity of the appliance and its ability to perform consistently over time.

Regulatory compliance is a challenge that manufacturers must navigate. Different regions have varying standards and certifications that products must meet, which can be time-consuming and costly. Keeping up with these regulations and ensuring that air fryers are certified for sale in multiple markets is a significant hurdle.

The rise of online shopping has also introduced new challenges. Consumers are now more likely to research and purchase air fryers online, which means that manufacturers need to focus on creating high-quality product images and detailed descriptions. Additionally, the expectation for fast shipping and reliable customer service has increased.

Despite these challenges, the air fryer industry is poised for growth. As the global population continues to seek healthier cooking options, the demand for air fryers is likely to rise. Manufacturers that can adapt to these trends and challenges will be well-positioned to capture a larger share of the market.

The development of healthier cooking oils and cooking techniques is also a trend to watch. As consumers look for ways to enjoy their favorite fried foods with less guilt, new oils and methods that provide a similar taste and texture to traditional frying without the high fat content are becoming more prevalent.

Lastly, the air fryer industry must address the issue of food waste. With the increasing awareness of the environmental impact of food waste, manufacturers are exploring ways to design air fryers that can help reduce the amount of food that is discarded, potentially through features that make it easier to cook only the amount of food needed.

In conclusion, the air fryer industry is facing a mix of exciting opportunities and significant challenges. By embracing innovation, focusing on sustainability, and adapting to the changing needs of consumers, manufacturers can navigate the future landscape successfully.

In the ever-evolving landscape of air fryer manufacturing, innovation remains the cornerstone of success. The industry’s journey has been marked by leaps in technology, design, and functionality, all of which have contributed to the widespread adoption of air fryers in homes and commercial kitchens alike. As we reflect on the path taken so far, it’s clear that embracing innovation has been pivotal. Let’s delve into the nuances of this transformative approach in air fryer manufacturing.

The industry has witnessed a shift from traditional cooking methods to healthier alternatives, with air fryers leading the charge. These compact appliances have revolutionized the way we think about cooking, offering a quick, efficient, and healthier option to deep-frying. The integration of smart technology and advanced features has made air fryers not just a gadget but a staple in modern kitchens.

Innovation in air fryer manufacturing often involves rethinking the very core of the appliance’s design. For instance, the introduction of variable temperature controls allows users to achieve a perfect crispness without the excess oil typically associated with deep frying. This shift in design has not only made air fryers more appealing to health-conscious consumers but has also expanded their versatility, allowing for a wider range of recipes.

Functionality has also seen significant advancements. Modern air fryers are equipped with features like pre-programmed cooking modes for different types of foods, LED screens for easy temperature adjustments, and even Wi-Fi connectivity for remote monitoring and control. These features not only enhance the user experience but also make air fryers more accessible to a broader audience.

The role of mold making service in this innovation cannot be overstated. The precision and quality of the molds used in manufacturing air fryers directly impact the performance and durability of the appliance. A high-quality mold ensures that each part is uniform, which is crucial for the appliance’s ability to distribute heat evenly and achieve consistent cooking results.

In addition to the technical aspects, the use of advanced molds has allowed manufacturers to explore new shapes and sizes, catering to various consumer preferences. From countertop models to built-in units, the variety of air fryers available today is a testament to the creative freedom enabled by precise mold making.

Data and trend analysis have become integral to product development. By studying consumer behavior, market demands, and technological advancements, manufacturers can stay ahead of the curve. For example, the growing trend towards sustainability has led to the development of air fryers made with eco-friendly materials and designed for energy efficiency.

In the realm of mold making services, the focus on sustainability is also evident. Manufacturers are increasingly seeking out partners who can provide molds made from biodegradable materials, reducing the environmental footprint of air fryer production.

As the air fryer industry continues to grow, challenges persist. One of the most significant challenges is maintaining the balance between innovation and cost. While consumers are willing to invest in high-quality air fryers, there’s always the pressure to keep prices competitive. This challenge necessitates a careful cost-benefit analysis during the manufacturing process.

Another challenge is ensuring product safety and compliance with various regulatory standards. With the integration of smart technology, air fryers must meet stringent safety requirements to protect users from potential hazards. This aspect of product development demands meticulous attention to detail and a commitment to quality.

The future of air fryer manufacturing is bright, but it’s also complex. The industry must navigate the delicate balance between innovation, cost-effectiveness, and safety. As we look ahead, we can expect to see continued advancements in design, functionality, and sustainability. The key to success will be the ability to adapt to these evolving demands while staying true to the core values that have made air fryers a beloved kitchen staple.

In conclusion, the journey of air fryer manufacturing is a story of innovation, perseverance, and adaptability. From the creation of precision molds to the integration of smart technology, each step has brought us closer to a future where cooking is not just healthier but also more convenient and enjoyable. Embracing innovation in air fryer manufacturing is not just a trend; it’s the driving force behind the industry’s continued growth and evolution.