Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary innovation meets commercial necessity, the commercial sandwich press stands as a testament to the ever-evolving landscape of foodservice technology. As we delve into the nuances of this compact yet powerful kitchen gadget, we explore its impact on efficiency, safety, and sustainability—a true reflection of the industry’s relentless pursuit of excellence.

The commercial kitchen landscape is constantly evolving, and one game-changer that’s been making waves is the NSF approved sandwich press. This innovative piece of equipment is revolutionizing the way chefs and operators approach sandwich preparation, offering a blend of convenience, efficiency, and quality that’s hard to beat.

Gone are the days when sandwiches were merely a side dish in the commercial kitchen. With the advent of the NSF approved sandwich press, these hearty meals have become the star of the show, drawing in customers with their irresistible appeal and the promise of a quick, satisfying bite. The rise of the sandwich press is a testament to the culinary industry’s quest for innovation and the demand for high-quality, consistent food.

What sets the NSF approved sandwich press apart from its predecessors is its unwavering commitment to safety and hygiene. The National Sanitation Foundation (NSF) is a globally recognized organization that sets the highest standards for public health and safety. By adhering to these stringent criteria, the sandwich press ensures that foodservice establishments are delivering meals that not only taste great but are also safe for consumption.

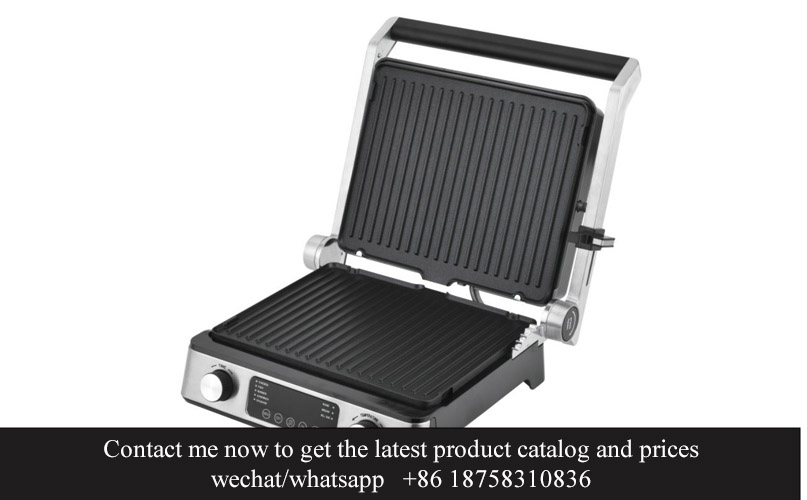

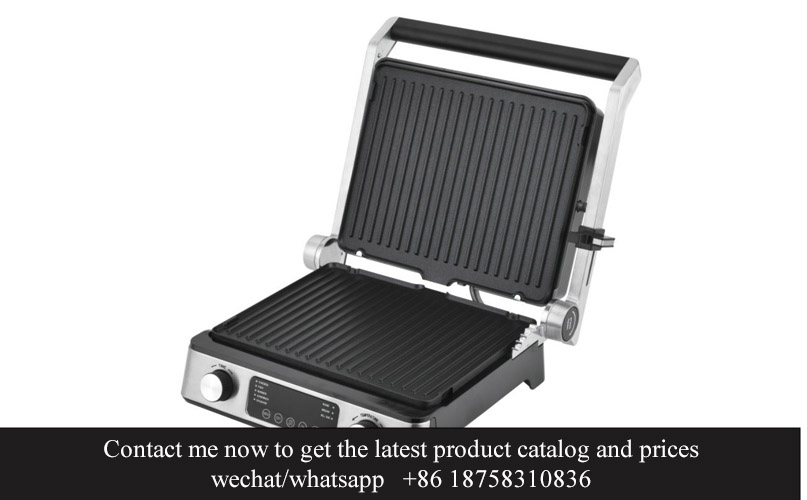

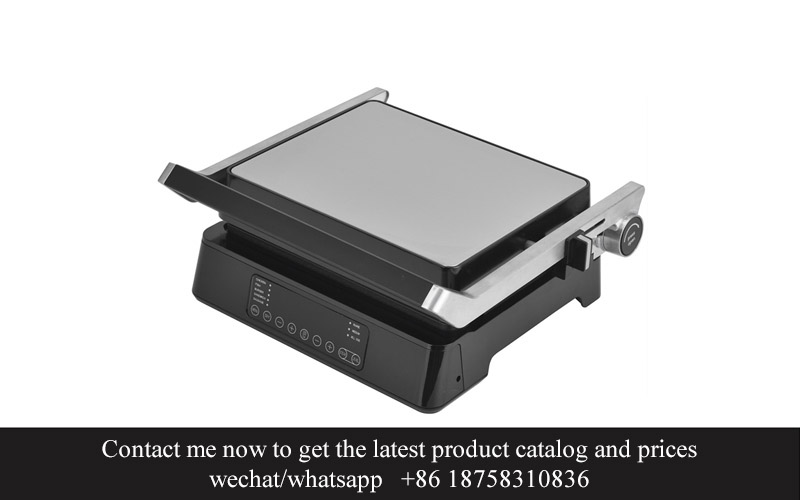

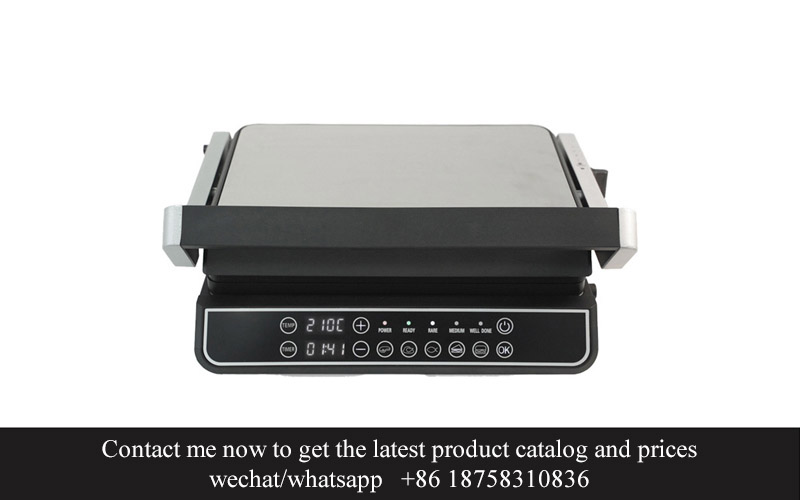

The design of the sandwich press is both intuitive and advanced. It features a sleek, modern look that fits seamlessly into any commercial kitchen setting. The non-stick surfaces and easy-to-clean materials make maintenance a breeze, saving valuable time and resources. But it’s not just about aesthetics and convenience; the technology behind the sandwich press is what truly revolutionizes the cooking process.

One of the standout features is the precise heat control. The press can be adjusted to different temperature settings, allowing chefs to achieve the perfect doneness for each type of sandwich. Whether you’re preparing a crispy, toasted ham and cheese or a juicy, melt-in-your-mouth turkey sub, the sandwich press ensures that every bite is a delightful experience.

The compact size of the sandwich press is another factor that contributes to its popularity. It takes up minimal counter space, making it ideal for busy kitchens where every square inch counts. Its portability also means it can be easily moved around, allowing for flexibility in menu planning and event catering.

Efficiency is at the heart of the sandwich press’s design. The quick-cook feature means that sandwiches can be prepared in a fraction of the time it would take with traditional methods. This is especially beneficial during peak hours when speed of service is crucial. The ability to cook multiple sandwiches simultaneously also boosts productivity, allowing kitchens to handle larger crowds without sacrificing quality.

In terms of health and safety, the NSF approval is a game-changer. It guarantees that the sandwich press is free from harmful chemicals and materials, ensuring that the food being cooked is safe for customers with allergies or dietary restrictions. This not only protects the health of your patrons but also builds trust and credibility with your customer base.

The impact of the NSF approved sandwich press on the culinary scene is undeniable. It has become a staple in many high-end restaurants, fast-food chains, and even in the bustling streets of food trucks. Its versatility has also made it a favorite among caterers and event planners, who appreciate the ability to serve up delicious sandwiches on the go.

As the sandwich press continues to gain popularity, we’re seeing a surge in creative sandwich offerings. From gourmet options with artisanal toppings to vegan and gluten-free alternatives, the possibilities are endless. The sandwich press has opened the door to new culinary experiences, pushing the boundaries of what a sandwich can be.

In the ever-competitive world of commercial cooking, staying ahead of the curve is key. The NSF approved sandwich press is not just a trend; it’s a testament to the industry’s commitment to innovation, quality, and customer satisfaction. As more operators discover the benefits of this remarkable piece of equipment, it’s only a matter of time before the sandwich press becomes an integral part of every commercial kitchen.

The NSF Approval stands as a beacon of trust and quality within the commercial kitchen equipment industry. It’s a mark that signifies not just adherence to stringent safety standards but also a commitment to excellence in design and functionality. When a sandwich press bears the NSF seal, it’s a guarantee that it has been rigorously tested for durability, cleanliness, and safety, ensuring that operators can provide their customers with products that meet the highest health and safety requirements.

In the competitive world of commercial cooking, the NSF certification is a differentiator. It’s not just about meeting minimum standards; it’s about exceeding them. The approval process involves a thorough examination of the product’s design, materials, and manufacturing process. This ensures that the sandwich press, from the moment it’s turned on, will perform consistently and safely, day in and day out.

The NSF, or National Sanitation Foundation, is an independent, non-profit organization that has been setting the bar for public health and safety since 1944. Their approval process is not just about checking if the sandwich press can withstand high temperatures and pressure; it’s also about ensuring that the device does not emit harmful substances into the food it prepares.

The certification process for a sandwich press is meticulous. It includes physical testing, such as checking the pressure distribution across the cooking surface to ensure even heating, as well as material analysis to confirm that there are no harmful chemicals present that could leach into the food. The NSF also examines the ease of cleaning, as a critical factor in maintaining hygiene in a commercial kitchen environment.

One of the key aspects of the NSF Approval is its emphasis on user safety. The sandwich press must be designed with the operator’s well-being in mind, featuring non-slip surfaces, ergonomic handles, and easy-to-use controls. This is particularly important for a sandwich press, as it is often used by multiple cooks throughout the day and must be safe for all skill levels.

Moreover, the NSF Approval is not just a one-time achievement. It is a continuous process that requires the manufacturer to adhere to strict guidelines even after the product has been certified. This ongoing commitment to quality and safety means that any issues that arise post-certification can be swiftly addressed, ensuring that the sandwich press remains a reliable and safe tool in commercial kitchens.

The NSF’s rigorous testing also includes a focus on electrical safety. Since sandwich presses are often powered by electricity, the certification process includes tests to ensure that the devices are built to withstand electrical surges and do not pose a risk of electric shock to the user. This is crucial for preventing accidents and ensuring that the kitchen remains a safe workplace.

In the realm of foodservice, the NSF Approval has become synonymous with trust. It’s a mark that tells restaurant owners, chefs, and customers that the equipment they are using is not just effective, but also safe. For operators, this certification can be a major selling point when it comes to attracting health-conscious consumers who are increasingly aware of the importance of food safety.

For manufacturers, the NSF Approval is a testament to their dedication to innovation and quality. It’s a signal that they are willing to go the extra mile to ensure that their products are at the forefront of industry standards. By choosing an NSF Approved sandwich press, a commercial kitchen is making a statement about its commitment to providing the best possible experience for both its staff and its patrons.

In summary, the NSF Approval is more than just a stamp of approval on a product; it’s a comprehensive assessment of its entire lifecycle. It’s a guarantee that the sandwich press has been engineered to the highest standards, from its design to its operation, and that it will continue to meet those standards throughout its service life. In an industry where safety and quality are paramount, the NSF Approval is a gold standard that stands out as a mark of distinction.

In the bustling world of commercial kitchens, where efficiency and culinary artistry meet, the sandwich press has emerged as a game-changer. This isn’t just any kitchen gadget; it’s a marvel of modern innovation that has redefined the way sandwiches are prepared and served. Let’s delve into the reasons why the sandwich press has become a staple in the commercial kitchen landscape.

The sandwich press is designed with precision and functionality in mind. Its sleek, compact design allows for easy integration into any kitchen setup, from bustling cafes to busy restaurants. The ease of use is undeniable, with a simple press mechanism that ensures even cooking and a perfect crust on every sandwich, every time. This consistency is crucial in maintaining high-quality standards and customer satisfaction.

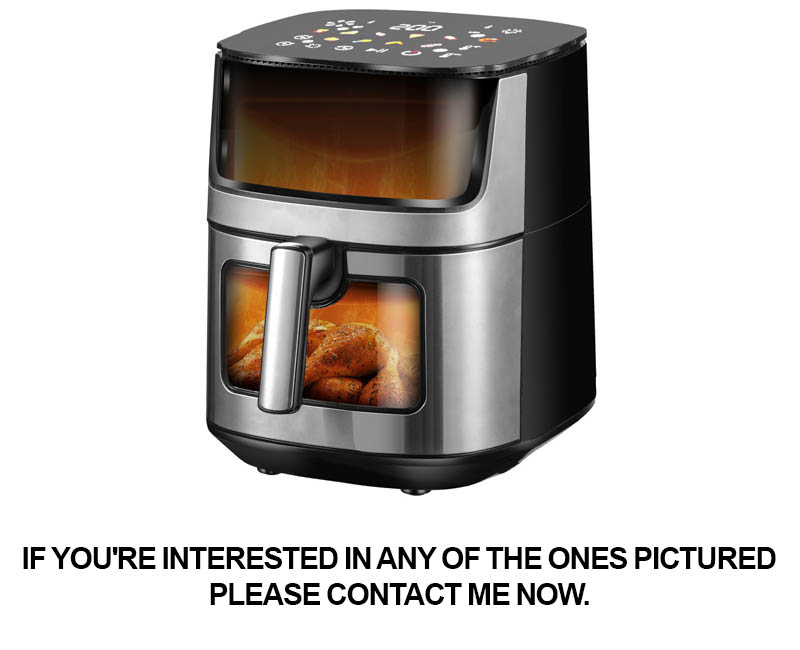

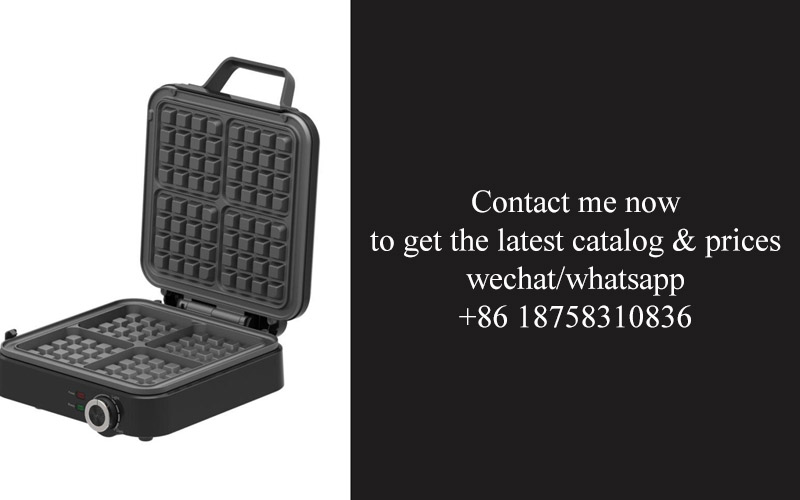

One of the standout features of the sandwich press is its versatility. It’s not just limited to making traditional sandwiches; it can also be used to cook a variety of other items, such as wraps, paninis, and even flatbreads. This adaptability means that chefs can offer a diverse menu without the need for multiple appliances, saving space and reducing the complexity of the kitchen workflow.

The technology behind the sandwich press is where it truly shines. Many modern models come equipped with non-stick surfaces that not only make cleaning a breeze but also ensure that food releases easily, minimizing the risk of burning. Some presses even feature adjustable heat settings, allowing chefs to tailor the cooking temperature to the specific requirements of different ingredients and recipes.

Another innovation worth noting is the inclusion of steam functions. This feature adds moisture to the cooking process, which is particularly beneficial for creating tender and juicy sandwiches. The steam also helps to lock in the flavors, resulting in a more aromatic and delectable final product.

Safety is a paramount concern in commercial kitchens, and the sandwich press addresses this with its robust construction. Made from high-quality, heat-resistant materials, these presses can withstand the rigors of high-heat cooking without compromising on durability. The ergonomic handles and non-slip bases provide a secure grip, reducing the risk of accidents.

Energy efficiency is also a key consideration for modern commercial kitchens. The sandwich press is designed to use energy wisely, reducing utility bills and minimizing the kitchen’s carbon footprint. With features like automatic shut-off mechanisms, these presses ensure that energy is conserved when not in use.

In terms of maintenance, the sandwich press is a breeze to clean. The non-stick surfaces make it easy to wipe away any residue, and most models are also dishwasher-safe, further simplifying the cleaning process. This not only saves time but also ensures that the press is ready for use at a moment’s notice.

The sandwich press has also embraced the digital age with digital temperature controls. These controls allow for precise and consistent cooking temperatures, which is essential for achieving the perfect finish on every sandwich. Chefs can now easily set and monitor the cooking temperature, ensuring that each batch of sandwiches is cooked to perfection.

From a business perspective, the sandwich press offers a significant competitive advantage. It can help streamline kitchen operations, reduce labor costs, and increase throughput. With the ability to cook multiple sandwiches simultaneously, the press is an efficient tool that can handle high-volume orders without compromising on quality.

Moreover, the sandwich press has become a favorite among health-conscious consumers. Its ability to cook sandwiches with minimal oil and at lower temperatures makes it a healthier option compared to traditional frying methods. This aligns with the growing demand for healthier fast-food alternatives and can be a strong selling point for restaurants looking to cater to this market segment.

In conclusion, the sandwich press is more than just a kitchen appliance; it’s a testament to the ingenuity of modern culinary technology. Its innovative design, versatility, safety features, energy efficiency, and ease of maintenance make it an indispensable tool for any commercial kitchen. As the demand for high-quality, efficient, and healthy food options continues to rise, the sandwich press is poised to remain a pivotal player in the commercial kitchen revolution.

The NSF Approved Sandwich Press has emerged as a game-changer in commercial kitchen equipment. This versatile appliance boasts a range of key features that not only enhance efficiency but also elevate the quality of the final product. Here are some of the standout aspects of this innovative press:

Stainless Steel Construction: The sandwich press is crafted from high-quality stainless steel, ensuring durability and longevity. This material is not only robust but also resistant to corrosion, making it a reliable choice for busy commercial kitchens.

Even Heat Distribution: A key feature of the NSF Approved Sandwich Press is its even heat distribution capabilities. The even heating ensures that the sandwiches are cooked to perfection on all sides, with a golden brown crust and a perfectly toasted interior.

Adjustable Heat Settings: To cater to a variety of sandwich preferences, this press offers adjustable heat settings. From a warm-up setting for soft and juicy sandwiches to a higher heat for a crisp, toasted exterior, operators have full control over the cooking process.

Large Capacity: Designed for high-volume operations, the sandwich press is spacious enough to handle multiple sandwiches at once. This not only increases productivity but also ensures a consistent and efficient workflow.

Safety Features: Safety is paramount in commercial kitchens, and this press does not disappoint. It includes features such as a non-slip base to prevent accidents and a cool-touch handle that keeps operators safe from burns during use.

Easy-to-Clean Design: Kitchens are busy places, and cleaning equipment can be a time-consuming task. The NSF Approved Sandwich Press is designed with ease of cleaning in mind. The flat surfaces and non-porous material make it quick and simple to wipe down, reducing downtime and ensuring a hygienic cooking environment.

Energy Efficiency: Commercial kitchens are under constant pressure to reduce energy costs. The sandwich press is energy-efficient, consuming less power while still delivering optimal cooking performance. This feature can lead to significant savings over time.

Compact and Space-Saving: Despite its large capacity, the sandwich press is designed to be compact and space-saving. It fits seamlessly into various kitchen layouts, maximizing the available space without compromising on functionality.

Versatility: The press is not limited to just sandwiches. It can be used to toast a variety of items, including bagels, pastries, and even vegetables, making it a versatile addition to any kitchen menu.

Ergonomic Design: The handle and overall design of the sandwich press are ergonomic, reducing the strain on operators’ hands and arms. This feature is especially important for those working long shifts in high-pressure environments.

Maintenance-Free: The press requires minimal maintenance, with no complex parts or moving components that can break down. This ensures that the kitchen can rely on the press for years to come without frequent service calls.

User-Friendly Interface: The control panel is straightforward and easy to navigate, allowing operators to set the desired heat levels and cooking times without confusion or delays.

Enhanced Presentation: The even cooking and toasted surfaces of the sandwich press help enhance the visual appeal of the final product, which is crucial for attracting customers and maintaining a high level of satisfaction.

Professional Results: Whether it’s for a casual café or a fine dining establishment, the NSF Approved Sandwich Press delivers professional results every time, helping maintain consistent quality across all shifts.

In summary, the NSF Approved Sandwich Press is a testament to the advancements in commercial kitchen equipment. Its combination of features ensures that it stands out in terms of quality, safety, efficiency, and versatility, making it an essential tool for any kitchen aiming to serve delicious sandwiches and a variety of toasted items.

In the fast-paced world of commercial kitchens, efficiency is paramount. The NSF Approved Sandwich Press stands out as a game-changer, significantly enhancing productivity in high-volume operations. Here’s how it does it:

The precision engineering of the NSF Approved Sandwich Press ensures consistent pressure distribution, which in turn guarantees uniform cooking. This means that every sandwich comes out perfectly toasted, with the right amount of crispiness on the outside and a melt-in-your-mouth texture on the inside. Such consistency is a hallmark of efficiency, allowing chefs to serve a high volume of sandwiches with minimal waste and rework.

The speed at which the NSF Approved Sandwich Press operates is unparalleled. Designed for rapid heating and even cooking, it can toast multiple sandwiches at once, reducing the time it takes to prepare each order. This is particularly beneficial in busy lunch hours or during peak dining periods, where seconds can mean the difference between a satisfied customer and a long queue.

Ease of use is a cornerstone of the NSF Approved Sandwich Press. Its intuitive controls and simple operation mean that staff can quickly learn how to use it, minimizing training time and allowing for a seamless transition into high-volume production. The press’s design also ensures that it’s easy to clean, which is crucial in maintaining hygiene standards and reducing downtime.

The compact and space-saving design of the NSF Approved Sandwich Press is a practical solution for commercial kitchens with limited space. By fitting effortlessly into counters and workstations, it frees up valuable real estate that can be used for other essential equipment or food preparation areas. This strategic use of space is a subtle yet effective way to streamline operations and maximize efficiency.

The sandwich press’s ability to cook a variety of food items, not just sandwiches, is a testament to its versatility. From wraps to paninis, the press can handle a diverse menu, reducing the need for multiple appliances and simplifying the workflow. This adaptability means that kitchens can cater to a wider range of preferences and dietary needs without compromising on speed or quality.

Safety features are integral to the NSF Approved Sandwich Press, making it a reliable choice for high-volume operations. The automatic shut-off function ensures that the press is turned off if left unattended for an extended period, preventing accidents and potential fires. This peace of mind is invaluable in a busy kitchen environment where safety is a top priority.

The sandwich press’s durability is another key feature that contributes to its efficiency in high-volume settings. Constructed with high-quality materials, it withstands the rigors of constant use, ensuring that it remains a reliable tool for years to come. This longevity means fewer breakdowns and less time spent on maintenance, allowing the kitchen to maintain its high level of productivity.

In addition to its functional benefits, the NSF Approved Sandwich Press is designed with the environment in mind. By using less energy than traditional cooking methods, it helps reduce the kitchen’s carbon footprint. This eco-friendly approach is not only good for the planet but also for the bottom line, as it can lead to significant savings on energy costs over time.

The NSF Approved Sandwich Press also offers flexibility in terms of customization. With various temperature settings and adjustable cooking times, chefs can tailor the press to their specific needs, ensuring that each sandwich is cooked to perfection. This level of control is essential in maintaining consistency and meeting the expectations of discerning customers.

In summary, the NSF Approved Sandwich Press is a marvel of modern kitchen technology. Its combination of speed, precision, ease of use, safety, and versatility makes it an indispensable tool for high-volume operations. By investing in this innovative appliance, commercial kitchens can significantly boost their efficiency, ensuring that they can handle even the busiest shifts with ease and success.

The implementation of NSF certified equipment in commercial kitchens is not just a trend; it’s a cornerstone of operational excellence and safety. Here’s how these health benefits translate into real-world advantages:

In high-pressure environments, the cleanliness and sanitation of cooking equipment are paramount. NSF certification ensures that the sandwich press, with its intricate parts and surfaces, is rigorously tested for cleanliness, reducing the risk of cross-contamination. This is particularly crucial in sandwich shops and delis where a variety of ingredients are handled daily.

The health benefits extend to the longevity of the equipment itself. NSF certified sandwich presses are designed with materials and construction methods that resist corrosion and degradation, which can lead to the release of harmful substances into food. This not only protects consumers from potential health risks but also ensures that the sandwich press remains a reliable tool for years to come.

Moreover, the precision of the heating elements in an NSF certified sandwich press helps to maintain consistent temperatures. This is vital for ensuring that food is cooked to the appropriate temperature, which is essential for food safety. Undercooked food can harbor harmful bacteria, while overcooked food can lose its flavor and nutritional value. The precise control offered by these presses is a game-changer in maintaining the integrity of the food served.

The design of NSF certified sandwich presses often includes features like adjustable heat settings and non-stick surfaces. These innovations make it easier for kitchen staff to achieve the perfect sandwich every time, reducing the likelihood of burns or undercooking. A sandwich press that consistently delivers the right results not only improves customer satisfaction but also minimizes the risk of foodborne illnesses.

Regular maintenance is a cornerstone of food safety, and NSF certified equipment is designed with this in mind. The clear, accessible components of these presses allow for easy cleaning and maintenance, which is critical for preventing the buildup of bacteria and other pathogens. This proactive approach to safety not only protects customers but also ensures that the kitchen staff can work in a hygienic environment.

The use of NSF certified sandwich presses also has a positive impact on the kitchen staff. By reducing the risk of accidents and injuries due to burns or improperly cooked food, these presses create a safer work environment. This peace of mind allows staff to focus on their tasks, improving overall efficiency and morale.

In addition to physical health benefits, there are mental health advantages to using NSF certified equipment. Knowing that the food being prepared is safe and meets the highest standards can boost the confidence of kitchen staff, leading to a more positive work atmosphere. This can have a ripple effect, influencing the quality of service provided to customers.

The health benefits of NSF certified sandwich presses are not limited to the kitchen. They also extend to the broader community. By preventing foodborne illnesses, these presses contribute to public health, reducing the burden on healthcare systems and improving the overall well-being of the population.

Finally, the use of NSF certified equipment can also have financial benefits. While the initial investment may be higher, the long-term savings from reduced maintenance costs, increased efficiency, and lower risk of legal issues related to food safety can make the difference between a profitable business and one that struggles to stay afloat.

In summary, the health benefits of using NSF certified sandwich presses are multifaceted, impacting everything from the safety of the food to the mental health of the staff. These benefits are just one reason why they have become a staple in commercial kitchens worldwide.

In the bustling world of commercial kitchens, where efficiency and quality are paramount, customer testimonials often paint a vivid picture of success. Here are a few real-life stories that showcase the impact of using NSF certified equipment, particularly the sandwich press, on businesses and their customers.

A local café owner, Sarah, shared her experience, “Our sandwich sales have skyrocketed since we invested in the NSF approved sandwich press. The consistency and speed of the presses have been game-changers for us. Customers are thrilled with the even-toasting and the perfect texture of their sandwiches.”

At a bustling food truck, the chef, Alex, raved about the sandwich press, “The compact design of the NSF certified sandwich press has been a lifesaver for us. We serve a high volume of customers, and this press allows us to keep up with the demand without compromising on quality. It’s a must-have for any mobile kitchen.”

A school cafeteria manager, Emily, noted, “The health benefits of using the NSF approved sandwich press are undeniable. It allows us to serve our students a variety of nutritious sandwiches, knowing that the equipment meets the highest safety standards. The feedback from the kids has been fantastic!”

A gourmet sandwich shop, led by Chef Mark, has seen a significant boost in their business thanks to the sandwich press, “The precision and control that the NSF certified sandwich press offers have allowed us to experiment with different types of bread and fillings. Our customers are now enjoying a wider variety of gourmet sandwiches, and our sales have never been better.”

In a busy hospital cafeteria, the head chef, Lisa, expressed her satisfaction, “The sandwich press has been a valuable addition to our kitchen. It’s easy to clean, which is crucial in a healthcare setting, and it ensures that our patients receive a hot, freshly toasted sandwich every time. The convenience and reliability of the NSF approved equipment have been invaluable.”

A sports stadium concession stand manager, John, shared his story, “Our customers expect quick service, especially during high-traffic events. The NSF approved sandwich press has been a game-changer for us. It allows us to serve up to 100 sandwiches an hour without any issues. The consistency and speed have been a hit with our patrons.”

A catering company owner, Michael, praised the sandwich press, “We cater to a wide range of events, from small corporate gatherings to large weddings. The NSF certified sandwich press has been a versatile tool that we rely on to deliver top-notch sandwiches to our clients. The quality and safety of the equipment are second to none.”

In a fast-food chain, the operations manager, Maria, said, “Our sandwich press has become a staple in our kitchen. It’s not just about the speed; it’s about the quality and safety of the product we serve. The NSF certification gives us peace of mind, knowing that we’re providing our customers with a safe and hygienic meal.”

A vegan café owner, Olivia, noted the sandwich press’s versatility, “We offer a variety of vegan sandwiches, and the NSF approved press has made it possible for us to cater to our customers’ dietary preferences. The ability to customize each sandwich to perfection has been a huge hit, and our sales have gone through the roof.”

These testimonials from diverse businesses across various industries highlight the tangible benefits of using NSF certified sandwich presses. From increased sales and customer satisfaction to operational efficiency and health benefits, the impact of this equipment is clear. It’s no wonder that more and more commercial kitchens are turning to NSF certified solutions to elevate their service and meet the demands of their customers.

The demand for high-quality commercial sandwich presses has been on the rise, reflecting a shift in the culinary landscape. From bustling cafes to busy restaurants, these appliances have become a staple in the commercial kitchen. Let’s delve into the factors driving this growth and the impact it has on the industry.

The Shift Towards ConvenienceConvenience is king in today’s fast-paced world, and the commercial sandwich press is a testament to this trend. Quick service restaurants (QSRs) and cafes are embracing these presses to churn out sandwiches at a rapid pace, satisfying the growing number of customers seeking a quick yet satisfying meal.

Versatility in Menu OfferingsHigh-quality commercial sandwich presses are not just for sandwiches anymore. They can be used to prepare a variety of items, from wraps and paninis to grilled cheese and even burgers. This versatility allows restaurants to diversify their menu without the need for multiple specialized appliances.

Consistency and UniformityOne of the key advantages of commercial sandwich presses is the ability to produce consistent results every time. The even heat distribution ensures that each sandwich is cooked to perfection, with a crispy outer layer and a tender interior. This level of consistency is crucial for maintaining customer satisfaction and brand reputation.

Efficiency in Kitchen LayoutsCommercial kitchens are always looking for ways to maximize space and efficiency. The compact design of sandwich presses allows them to be easily integrated into kitchen layouts, whether they are countertop models or freestanding units. This efficiency is especially valuable in kitchens with limited space.

Cost-Effective OperationDespite the premium quality, high-quality commercial sandwich presses are designed to be cost-effective. They are built to last, reducing the need for frequent replacements. Additionally, their energy-efficient design helps to lower utility bills, contributing to a more sustainable and cost-effective operation.

Technological AdvancementsThe latest models of commercial sandwich presses come equipped with cutting-edge technology. Features like adjustable heat settings, non-stick surfaces, and programmable timers allow operators to fine-tune the cooking process to their specific needs. These advancements not only improve the quality of the food but also make the appliance easier to use.

Health and Hygiene StandardsIn the wake of increased health consciousness, the demand for clean and hygienic food preparation is at an all-time high. NSF-certified commercial sandwich presses meet stringent health and safety standards, ensuring that the equipment is safe for use and easy to clean. This is a significant factor for restaurants looking to maintain high health and hygiene ratings.

Consumer Trends and PreferencesConsumer preferences are evolving, with a greater emphasis on fresh, made-to-order food. The rise of the sandwich press aligns with these trends, as it allows for the preparation of fresh sandwiches on the spot. This focus on freshness is a key driver in the demand for high-quality commercial sandwich presses.

Global Market ExpansionThe demand for high-quality commercial sandwich presses is not confined to a single region. As the global foodservice industry continues to grow, so does the need for efficient and reliable cooking equipment. This has led to an expansion of the market, with more manufacturers catering to international demand.

Sustainability and Eco-Friendly PracticesThe growing awareness of environmental issues has led to a surge in demand for eco-friendly products. High-quality commercial sandwich presses are often designed with sustainability in mind, featuring materials and components that are recyclable or have a lower environmental impact. This focus on sustainability is attracting more businesses that are committed to green practices.

In conclusion, the growing demand for high-quality commercial sandwich presses is a multifaceted trend driven by convenience, versatility, efficiency, cost-effectiveness, technological advancements, health and hygiene standards, consumer preferences, global market expansion, and sustainability concerns. As the foodservice industry continues to evolve, these appliances are poised to play a crucial role in shaping the future of commercial cooking.

In the ever-evolving world of commercial cooking, the importance of sustainability and energy efficiency cannot be overstated. As businesses strive to reduce their environmental footprint and cut costs, the adoption of greener cooking methods has become a priority. Here’s how sustainability and energy efficiency are reshaping the way we approach cooking in commercial kitchens.

The Shift Towards Energy-Efficient AppliancesModern commercial sandwich presses are designed with energy efficiency in mind. From the materials used in their construction to the technology that powers them, these appliances are engineered to minimize energy consumption. Features like thermostatic controls and heat retention systems ensure that energy is used effectively, reducing the operational costs for businesses.

Greener Materials and ConstructionOne of the key aspects of sustainability in cooking equipment is the use of environmentally friendly materials. Many high-quality sandwich presses are now made with recycled steel, which not only reduces the need for new raw materials but also helps in the reduction of waste. Additionally, the non-stick coatings used in these presses are free from harmful chemicals, making them safer for both the environment and the health of customers.

Energy-Saving Cooking TechniquesThe traditional method of cooking sandwiches involved multiple steps and often required a high level of heat, which was not only energy-intensive but also led to a significant amount of waste. Modern sandwich presses, however, use innovative cooking techniques that reduce energy usage. Induction heating, for instance, allows for precise temperature control, ensuring that heat is only used where it’s needed, and not wasted.

Reduced Carbon FootprintBy utilizing energy-efficient appliances, commercial kitchens can significantly reduce their carbon footprint. This not only benefits the environment but also helps businesses comply with increasingly stringent environmental regulations. The reduced energy consumption means less reliance on fossil fuels, contributing to a cleaner atmosphere and healthier planet.

Water ConservationIn addition to energy efficiency, sustainability also encompasses water conservation. Some sandwich presses are designed to use less water, which is particularly beneficial in commercial settings where water usage can be substantial. Features like water-saving nozzles and automatic shut-off systems help minimize water waste without compromising the quality of the food being prepared.

Cost Savings Over TimeWhile investing in energy-efficient and sustainable cooking equipment may require an upfront cost, the long-term savings can be substantial. Reduced energy and water bills, coupled with the longevity of these appliances, can lead to significant cost savings for businesses. This financial benefit is a compelling reason for commercial kitchens to adopt greener cooking methods.

Enhanced Reputation and Customer AppealA commitment to sustainability can enhance a business’s reputation and appeal to environmentally conscious customers. Many consumers today are looking for establishments that share their values, and a greener approach to cooking can be a major draw. By using NSF certified equipment, businesses can demonstrate their dedication to quality and safety, as well as their environmental responsibility.

Training and EducationTo fully capitalize on the benefits of sustainability and energy efficiency, it’s crucial for kitchen staff to be properly trained. Educating employees on how to use the equipment effectively and maintain it properly can maximize energy savings and reduce waste. This training not only contributes to the greener operation of the kitchen but also fosters a culture of sustainability within the organization.

Innovation in Design and FunctionalityThe development of sustainable cooking equipment has spurred innovation in design and functionality. Modern sandwich presses are not only energy-efficient but also feature advanced cooking capabilities that enhance the quality of the food. These innovations include adjustable heat settings, programmable cooking times, and even customizable press options to cater to a variety of sandwich preferences.

The Future of Sustainable CookingAs the demand for sustainable products and practices grows, the future of cooking in commercial kitchens looks promising. Continuous innovation in energy-efficient technology and materials will likely lead to even more efficient and sustainable cooking solutions. Businesses that embrace these advancements will be well-positioned to meet the expectations of environmentally conscious consumers while also enjoying the operational benefits of greener cooking methods.

The commercial sandwich press industry is on the brink of exciting advancements that promise to redefine the way we think about fast-food preparation. From smart technology integration to eco-friendly designs, the future of sandwich presses is shaping up to be both innovative and sustainable. Here’s a glimpse into what’s next for this dynamic sector.

Technology is rapidly evolving, and the commercial sandwich press industry is no exception. We’re seeing a surge in smart features that not only enhance the cooking process but also provide valuable data for kitchen management. For instance, presses with built-in sensors can monitor temperature and pressure, ensuring consistent results every time. This level of precision is a game-changer for high-volume operations that demand uniformity in their output.

Energy efficiency is another critical area where the industry is making strides. With the increasing focus on sustainability, manufacturers are developing sandwich presses that consume less power without compromising on performance. These energy-saving models not only reduce utility bills but also contribute to a greener planet. The integration of LED lighting and programmable settings is just the beginning of this energy-conscious revolution.

Customization is key in the fast-food industry, and the commercial sandwich press is no different. The future will see presses that offer a range of functionalities to cater to diverse menu items. From different press surfaces to adjustable temperature controls, these versatile machines will be able to handle everything from classic sandwiches to gourmet sliders. This adaptability will be a significant draw for restaurants looking to expand their offerings without the need for multiple specialized equipment.

The rise of mobile foodservice is another trend that’s influencing the sandwich press industry. As more businesses look to establish a presence in various locations, portable and compact sandwich presses are becoming increasingly popular. These units are designed to be lightweight and easy to transport, making them ideal for food trucks, pop-up restaurants, and temporary events. The convenience of these presses is set to open up new opportunities for entrepreneurs and foodservice providers alike.

Health and safety are paramount in commercial kitchens, and the industry is responding with innovations that prioritize these concerns. For example, presses with self-cleaning capabilities can help reduce the risk of cross-contamination and simplify the cleaning process. Additionally, the use of non-toxic materials and easy-to-access components ensures that equipment is both safe and easy to maintain.

In the realm of consumer trends, there’s a growing demand for healthier options. The commercial sandwich press industry is responding by offering presses that can accommodate a variety of ingredients, including whole grains, lean proteins, and fresh produce. This flexibility allows chefs to create nutritious, well-balanced sandwiches that cater to health-conscious diners.

Collaboration between manufacturers and chefs is also playing a significant role in shaping the future of sandwich presses. By working closely with culinary experts, companies are able to develop products that not only meet the demands of the industry but also push the boundaries of culinary innovation. This partnership is leading to the creation of presses that can achieve unique textures and flavors, setting new standards for the quality of fast-food sandwiches.

The rise of social media and online reviews has had a profound impact on the foodservice industry. As customers become more discerning about the quality of their meals, the pressure is on for businesses to deliver exceptional food consistently. The commercial sandwich press industry is answering this call by producing presses that are easy to use and maintain, ensuring that staff can focus on creating the best possible product without being hindered by inefficient equipment.

The future of the commercial sandwich press industry is also influenced by global events and economic factors. For instance, the rise of remote work has led to a surge in demand for home delivery services, which in turn requires efficient and reliable kitchen equipment. As the industry adapts to these changes, we can expect to see more versatile and user-friendly presses that can handle the demands of a rapidly evolving market.

In conclusion, the commercial sandwich press industry is poised for a transformative period. With a focus on technology, sustainability, customization, and health, the future holds promise for innovation that will not only improve the efficiency of high-volume operations but also enhance the overall dining experience. As the industry continues to evolve, it’s clear that the sandwich press will play a pivotal role in shaping the future of fast-food preparation.