Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, sandwich plates have emerged as a staple in modern culinary settings. These versatile devices, often crafted with precision and innovation, have become a cornerstone of efficient food preparation. As we delve into the intricacies of sandwich plate technology, it becomes clear that the role of integrated metal stamping is not just a component of design, but a pivotal factor in shaping the future of this industry.

The kitchen appliance industry has undergone a remarkable transformation over the years, with advancements in technology leading to sleeker, more efficient, and innovative designs. One such technological leap has been the integration of metal stamping into the production of sandwich plates. This method has not only revolutionized the manufacturing process but has also enhanced the functionality and durability of these kitchen essentials.

Metal stamping has emerged as a game-changer in the production of sandwich plates, offering a range of benefits that traditional manufacturing techniques simply couldn’t match. The process involves shaping metal sheets into the desired shapes and sizes using presses and dies, resulting in intricate and precise designs. This precision is crucial for creating sandwich plates that are not only visually appealing but also highly functional.

One of the key advantages of integrated metal stamping is its ability to produce complex geometries with ease. Sandwich plates, which often feature multiple layers and intricate patterns, can now be manufactured with a level of detail that was previously unattainable. This has allowed designers to push the boundaries of creativity, offering consumers a wider variety of styles and functionalities.

The efficiency of metal stamping is another significant factor contributing to its rise in the kitchen appliance industry. The process is highly automated, reducing the time and labor required to produce sandwich plates. This not only lowers production costs but also shortens lead times, ensuring that manufacturers can meet the growing demand for these products.

Durability is a critical aspect of kitchen appliances, and integrated metal stamping has significantly improved the lifespan of sandwich plates. The metal used in the stamping process is typically high-quality and resistant to corrosion, heat, and everyday wear and tear. This means that sandwich plates made using this technology are more likely to withstand the rigors of kitchen use, providing long-lasting value to consumers.

Moreover, the precision of metal stamping allows for better sealing and insulation in sandwich plates. This is particularly important for appliances that are designed to retain heat or keep food cold, such as thermal cookware. The tight tolerances achieved through metal stamping ensure that these appliances maintain their temperature integrity, making them more effective and energy-efficient.

The environmental impact of manufacturing processes is also a growing concern, and integrated metal stamping offers a more sustainable alternative. The automation and efficiency of the process reduce waste and energy consumption, aligning with the industry’s push towards more eco-friendly practices. Additionally, the materials used in metal stamping are often recyclable, further contributing to a greener manufacturing cycle.

As the kitchen appliance market continues to evolve, the demand for high-quality, innovative products has never been higher. Integrated metal stamping has played a pivotal role in this shift, enabling manufacturers to produce sandwich plates that are not only visually stunning but also highly functional and sustainable.

The integration of metal stamping into sandwich plate production has also opened up new opportunities for customization. Consumers today are looking for appliances that not only serve a purpose but also reflect their personal style. Metal stamping allows for a wide range of finishes and textures, from sleek and modern to rustic and traditional, catering to diverse tastes and preferences.

Innovation is at the heart of the kitchen appliance industry, and the rise of integrated metal stamping has fueled this drive. By continually pushing the boundaries of what is possible in design and functionality, the industry is setting the stage for a new era of kitchen appliances. Sandwich plates are just one example of how metal stamping is transforming the landscape, and it’s a trend that is likely to spread to other kitchen essentials in the coming years.

In conclusion, the integration of metal stamping in the production of sandwich plates has brought about a new level of sophistication and efficiency to the kitchen appliance industry. From enhanced durability and precision to environmental benefits and customization options, this technology is reshaping the way we think about kitchenware. As consumers demand more from their appliances, it’s clear that integrated metal stamping will continue to play a crucial role in meeting these expectations.

Sandwich plates, often a staple in kitchen appliances, are more than just a simple piece of cookware. These versatile devices are integral to a variety of culinary tasks, and their design and construction are a testament to the evolution of kitchen technology. Let’s delve into a brief overview of what makes a sandwich plate tick.

The sandwich plate is a multi-layered cookware item that consists of two outer plates and a middle core. This core can be made from a variety of materials, but it’s typically a non-stick surface that allows for even heat distribution. The outer plates, which are often made from metals like stainless steel, provide durability and resistance to high temperatures.

The non-stick core is where the magic happens. It’s designed to be easy to clean and to prevent food from sticking, making cooking a breeze. The materials used in the construction of the core must be heat-resistant and non-reactive, ensuring that the flavor of the food remains pure and unaltered.

The design of sandwich plates is also a marvel of modern engineering. The plates are often made with a hollow core, which allows for better heat retention and distribution. This means that whether you’re cooking a delicate dish or a hearty casserole, the sandwich plate can maintain a consistent temperature throughout the cooking process.

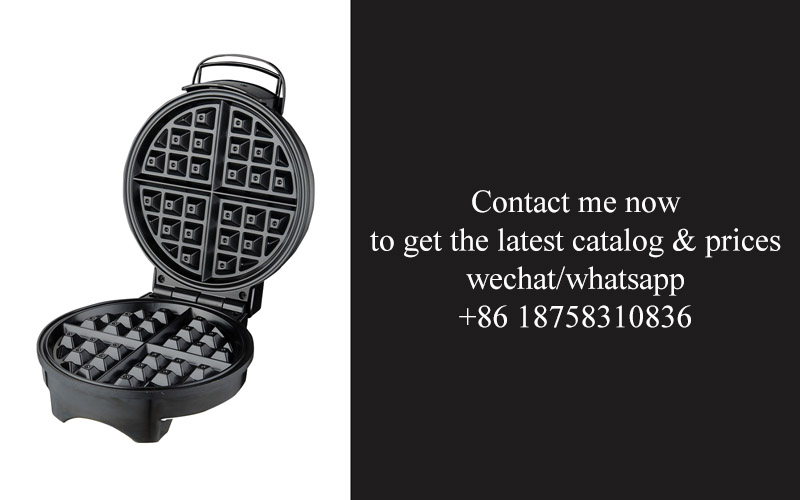

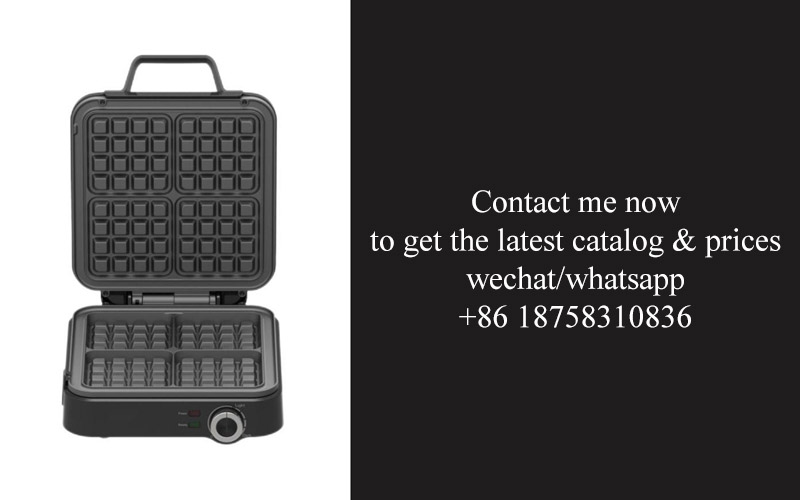

One of the key advantages of sandwich plates is their versatility. They can be used for a wide range of cooking methods, including baking, broiling, and grilling. This makes them a must-have for any kitchen, as they can replace multiple pieces of cookware with just one item.

When it comes to the materials used in sandwich plates, there are a few notable ones. Aluminum is a common choice for its excellent heat conductivity, but it can be prone to warping. Stainless steel, on the other hand, offers durability and a sleek look, but it doesn’t conduct heat as well as aluminum.

Ceramic is another popular material, offering a non-stick surface that is free from harmful chemicals. It’s also resistant to stains and can withstand high temperatures. However, ceramic is heavier than other materials and may not be suitable for all types of cooking.

In recent years, manufacturers have started experimenting with composite materials that combine the benefits of different elements. For example, some sandwich plates feature a ceramic core surrounded by a stainless steel outer shell, offering the best of both worlds in terms of non-stick properties and durability.

The construction of sandwich plates is also a critical factor. The layers must be bonded together securely to prevent warping or separation. Some plates use a vacuum brazing process to create a strong bond between the layers, while others rely on heat-sealed edges to ensure a tight fit.

When it comes to the cooking experience, sandwich plates can be a game-changer. The even heat distribution means that food is cooked thoroughly without burning or undercooking. The non-stick surface makes it easy to release food from the plate, and the durability means that the plate can withstand repeated use and high temperatures.

Despite their many benefits, sandwich plates aren’t without their drawbacks. The price can be a bit steep for some consumers, and the weight might be an issue for those with smaller kitchens or those who prefer lighter cookware. Additionally, some users have reported that the non-stick coating can wear down over time, leading to potential sticking and the need for frequent cleaning.

In the world of kitchen appliances, sandwich plates have certainly made their mark. They offer a unique combination of features that cater to both the health-conscious consumer and the busy chef. As technology continues to advance, we can expect to see even more innovative designs and materials being used in sandwich plates, making them an even more indispensable part of the modern kitchen.

In summary, sandwich plates are a marvel of modern cookware engineering, combining the ease of non-stick surfaces with the durability of high-quality materials. Their versatility in cooking methods and ability to maintain even heat distribution make them a favorite among chefs and home cooks alike. While they may not be perfect, the ongoing advancements in technology and materials promise a bright future for this versatile kitchen staple.

Integrated metal stamping has become a cornerstone in the design and production of sandwich plates, offering a myriad of advantages that enhance both functionality and aesthetics. Here’s a closer look at how this technology shapes the sandwich plate landscape.

The precision and consistency of metal stamping allow for intricate and uniform patterns in sandwich plates. This precision is crucial for creating the distinct layered structure of sandwich plates, where each layer plays a vital role in the overall performance. Whether it’s the non-stick coating on the cooking surface or the heat-resistant material on the exterior, the ability to stamp detailed patterns ensures that these layers are seamlessly integrated.

The use of metal stamping in sandwich plate design also enables the creation of complex geometries that are essential for the plate’s structure. The ability to form and shape metal into unique shapes ensures that the sandwich plate can withstand the rigors of cooking, including even heat distribution and resistance to warping or bending over time. The precision in forming these shapes is what allows for the creation of high-quality, durable sandwich plates.

One of the most notable benefits of integrated metal stamping is the customization it offers. Manufacturers can stamp metal with various textures, finishes, and designs, giving sandwich plates a personalized touch. This level of customization isn’t just about aesthetics; it also plays a role in the user experience. For instance, a textured surface on the cooking side of the plate can prevent food from sliding, improving grip and safety during cooking.

In terms of efficiency, metal stamping streamlines the manufacturing process. By using pre-designed stamping dies, manufacturers can produce multiple sandwich plates at once, significantly reducing production time and costs. This efficiency also translates to a lower environmental impact, as the streamlined process reduces waste and energy consumption.

The thermal conductivity of metal stamping materials is another key advantage. Sandwich plates often require materials that can withstand high temperatures without warping or losing their shape. Metal stamping allows for the use of metals with excellent heat transfer properties, ensuring that the sandwich plate can handle hot ingredients without compromising its structural integrity.

Durability is a crucial factor in the design of sandwich plates, and metal stamping contributes significantly to this aspect. The strength of the metal, combined with the precision of stamping, results in a plate that is less likely to crack, chip, or break, even with frequent use. This longevity not only benefits the consumer but also reduces the demand for frequent replacements.

In the realm of safety, metal stamping plays a pivotal role. The ability to create smooth, non-porous surfaces on sandwich plates is essential for preventing bacteria growth and making cleaning easier. The hygienic properties of these surfaces are a direct result of the metal stamping process, which ensures that every detail is crafted to the highest standard.

The design flexibility of metal stamping doesn’t end with the plate itself. The same technology can be used to create specialized accessories and attachments, such as lids, non-slip bases, or integrated heating elements. This integration of components not only enhances the functionality of the sandwich plate but also contributes to a cohesive, high-quality product that meets the evolving demands of consumers.

Finally, the scalability of metal stamping is a testament to its versatility. As the market for sandwich plates grows, manufacturers can easily adapt and expand their production to meet increased demand without sacrificing quality. This scalability ensures that the sandwich plate industry can continue to innovate and evolve, staying ahead of consumer trends.

In summary, the role of integrated metal stamping in sandwich plate design is multifaceted, offering benefits ranging from precision and durability to customization and efficiency. As the industry continues to advance, the integration of metal stamping will undoubtedly remain a cornerstone in the creation of high-quality, functional, and aesthetically pleasing sandwich plates.

In the world of kitchen appliances, sandwich plates have become a staple, offering a versatile and practical solution for a wide range of cooking tasks. The technology behind these plates has seen significant advancements, pushing the boundaries of what is possible in kitchenware. Here’s a look at some of the latest innovations shaping sandwich plate technology:

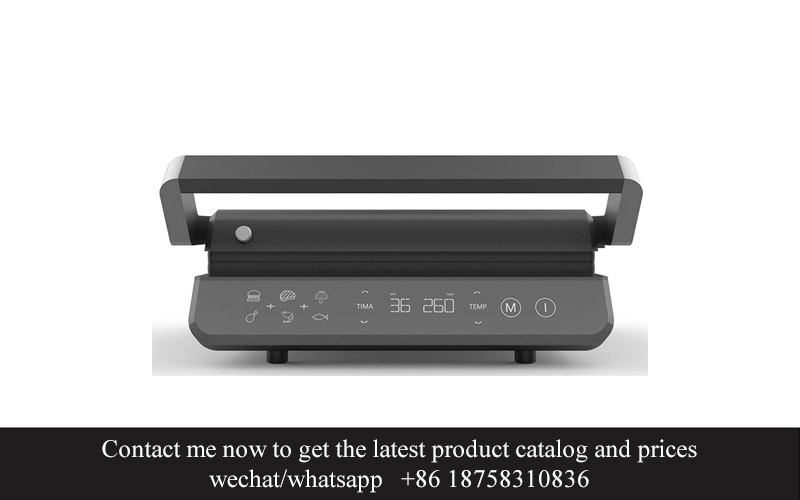

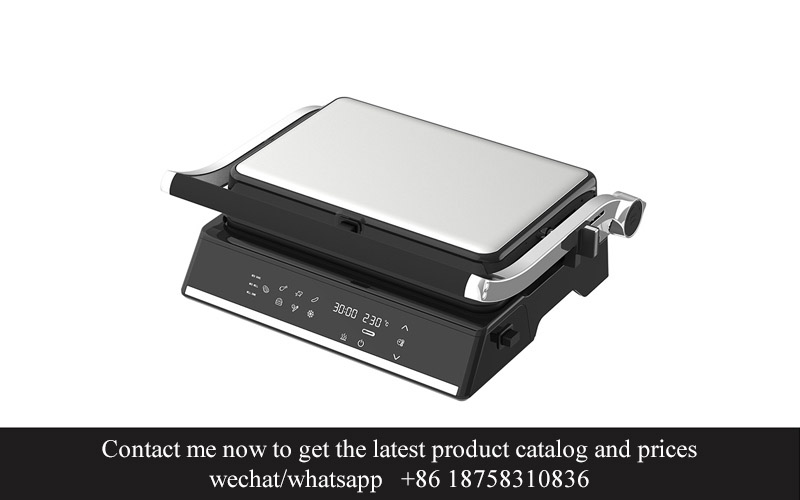

The integration of smart sensors has revolutionized sandwich plates, making them more than just cooking surfaces. Modern plates are now equipped with temperature sensors that provide real-time feedback, ensuring that food is cooked to perfection every time. These sensors can be calibrated to monitor specific types of ingredients or cooking methods, adding a layer of precision that was once only available in professional kitchens.

Designers have also embraced modular construction in sandwich plate technology. By creating plates with interchangeable components, users can customize their cooking experience based on the dish they’re preparing. This modular approach allows for the easy addition or removal of elements such as non-stick surfaces, heat diffusers, or specialized inserts for specific types of cooking, like sous-vide.

One of the most notable innovations is the use of advanced materials. High-grade metals, such as stainless steel and aluminum, are now commonly used in sandwich plates due to their excellent heat conductivity and durability. These materials not only enhance the cooking performance but also contribute to the longevity of the plates. Moreover, some manufacturers are experimenting with anodized coatings to improve the plates’ resistance to corrosion and to provide a non-stick surface that doesn’t require the use of harmful chemicals.

In terms of energy efficiency, sandwich plates have seen a shift towards induction cooking technology. Induction plates utilize magnetic fields to heat the food directly, eliminating the need for a traditional heating element. This not only reduces energy consumption but also provides a faster and more even cooking process. The integration of induction technology in sandwich plates has made them a favorite among eco-conscious consumers.

The inclusion of safety features is another area where sandwich plate technology has made significant strides. Many modern plates come with built-in safety shut-offs that automatically turn off the heat after a certain period of inactivity or once the cooking is complete. This not only prevents accidents but also ensures that energy is not wasted. Some models even feature a child lock feature to prevent accidental burns.

In the realm of aesthetics, sandwich plates have evolved to become more than just functional tools. The designs now incorporate sleek lines and modern finishes that complement contemporary kitchen decor. The use of innovative materials like ceramic and glass has introduced a new level of sophistication to the world of sandwich plates, making them not just a cooking tool but also a piece of kitchen art.

The addition of smart connectivity has opened up a whole new world for sandwich plates. With the help of Bluetooth or Wi-Fi, these plates can be controlled remotely through smartphones or tablets. Users can set cooking times, monitor progress, and even receive notifications when their food is ready. This level of connectivity not only adds convenience but also allows for the integration of cooking apps that offer personalized recipes and cooking guides.

Lastly, sustainability has become a key focus in sandwich plate technology. Manufacturers are exploring the use of recycled materials and sustainable production processes to reduce their environmental impact. This includes the development of biodegradable coatings and the use of renewable energy sources during the manufacturing process.

These innovations in sandwich plate technology reflect a deeper understanding of consumer needs and a commitment to advancing the art of cooking. As the technology continues to evolve, it’s clear that sandwich plates will remain a cornerstone of modern kitchen appliances, offering both functionality and cutting-edge features that make cooking a more enjoyable and efficient experience.

In recent years, the sandwich plate manufacturing industry has seen a surge in popularity, driven by evolving consumer tastes and the integration of new technologies. This segment of the kitchen appliances market is not only growing in size but also in complexity. Let’s delve into the current market trends and consumer demands shaping this dynamic industry.

The demand for convenience is at an all-time high, with consumers seeking products that can cater to fast-paced lifestyles. This has led to a rise in demand for sandwich plates that offer quick and easy food preparation. The compact and space-saving design of these plates is a testament to the industry’s responsiveness to this need.

Modern consumers are increasingly health-conscious, and this trend is reflected in the sandwich plate market. There’s a growing preference for plates that are not only durable but also non-toxic and easy to clean. Manufacturers are responding by using high-quality, food-grade materials that are free from harmful chemicals, ensuring safety and sustainability.

Customization has become a key factor in the sandwich plate market. Consumers are looking for products that can be tailored to their specific preferences, from size and shape to the inclusion of specific features like dividers or removable sections. This has spurred the development of innovative manufacturing processes that allow for greater flexibility in design.

Eco-friendly practices are becoming more mainstream, and the sandwich plate industry is no exception. There’s a noticeable shift towards environmentally friendly materials and production methods. Biodegradable plastics and recycled metals are being used to reduce the carbon footprint and promote sustainability.

Smart features are making their way into the sandwich plate market, appealing to tech-savvy consumers. Digital temperature controls, Bluetooth connectivity for monitoring and adjusting settings remotely, and even plates that can provide nutritional information are becoming more common. These advancements are enhancing the user experience and adding value to the product.

The rise of the mobile workforce has also influenced consumer demand. As more people work from home or travel frequently, there’s a need for portable and versatile sandwich plates that can be easily transported and used in various settings. Compact, lightweight, and durable designs are in high demand to cater to this demographic.

Globalization has expanded the market for sandwich plates, as consumers are exposed to a wider range of international cuisines. This has led to an increase in demand for plates that can accommodate different types of food, including those with varied temperatures or textures. The industry is responding with multi-functional plates that can handle a variety of food items.

The trend towards meal prepping is also driving demand for sandwich plates. Busy individuals are looking for products that can help them organize their meals throughout the week. Meal prep containers that are stackable, easy to label, and microwave-safe are becoming increasingly popular.

In the realm of aesthetics, there’s a shift towards more sophisticated and stylish designs. Consumers are no longer just looking for functional plates but also for those that can enhance the visual appeal of their kitchen or dining area. This has led to the development of sandwich plates with sleek, modern designs that blend seamlessly with contemporary decor.

The sandwich plate manufacturing industry is also witnessing a rise in the use of advanced manufacturing techniques. The integration of automated systems and robotics has not only increased efficiency but has also allowed for the production of complex and intricate designs that were previously unattainable.

Safety standards are also a significant concern. With recalls and product safety issues making headlines, consumers are more cautious about the materials and construction of their kitchenware. As a result, there’s an emphasis on rigorous testing and quality control to ensure that sandwich plates meet the highest safety standards.

In conclusion, the sandwich plate manufacturing industry is being shaped by a combination of convenience, health consciousness, customization, sustainability, technology, and aesthetic considerations. As these trends continue to evolve, the industry will need to stay agile and innovative to meet the ever-changing demands of consumers.

In the realm of sandwich plate manufacturing, integrated metal stamping has emerged as a pivotal technology, transforming the way these versatile kitchenware items are produced. Let’s delve into some case studies that showcase the successful implementation of this innovative technique.

The first case study involves a leading manufacturer of sandwich plates that sought to enhance the durability and aesthetic appeal of their products. By integrating metal stamping into the production process, they were able to create plates with intricate patterns and reinforced edges, which not only added a touch of sophistication but also improved the overall strength of the plates.

In another instance, a mid-sized company specializing in eco-friendly kitchenware wanted to reduce their carbon footprint. They turned to integrated metal stamping, which allowed them to use less material while maintaining the structural integrity of the sandwich plates. This innovation not only helped the company meet environmental standards but also reduced production costs.

A global brand known for its high-end kitchenware line faced a challenge in producing sandwich plates that could withstand the rigors of international shipping. Through the adoption of advanced metal stamping techniques, they developed a lightweight yet robust design that minimized damage during transit. This allowed the company to offer a premium product without compromising on quality or cost.

A smaller, family-owned business that produces a variety of kitchenware items found that integrated metal stamping could be applied to create custom sandwich plates. By leveraging this technology, they were able to cater to niche markets and individual customer requests, which in turn, increased their market share and customer loyalty.

In a different scenario, a manufacturer of commercial-grade sandwich plates aimed to improve the efficiency of their production line. They integrated metal stamping into their process, which not only increased production speed but also reduced the number of steps required to create each plate. This streamlined approach not only boosted productivity but also allowed the company to expand their product line without overextending their resources.

A well-known brand that produces a wide range of kitchenware products faced the challenge of creating sandwich plates that could be easily cleaned and maintained. By incorporating metal stamping, they were able to design plates with smooth, non-porous surfaces that resisted stains and were dishwasher-friendly. This innovation was a hit with consumers, leading to increased sales and positive feedback.

A manufacturer of outdoor kitchenware recognized the potential of integrated metal stamping to create sandwich plates that could withstand harsh weather conditions. They developed a line of plates with a special coating applied through the stamping process, which provided an additional layer of protection against rust and corrosion. This allowed their products to stand out in the competitive outdoor market.

In one final case study, a company that produces a wide variety of metal kitchenware items discovered that integrated metal stamping could be used to create sandwich plates with built-in cutting surfaces. This innovation eliminated the need for additional tools and made meal preparation more convenient for users. The success of this product line helped the company diversify its offerings and attract a broader customer base.

These case studies illustrate the versatility and potential of integrated metal stamping in sandwich plate manufacturing. From enhancing durability and aesthetics to improving production efficiency and catering to niche markets, this technology has proven to be a game-changer in the industry. As manufacturers continue to explore new applications and advancements in metal stamping, the possibilities for innovation in sandwich plate design and functionality seem endless.

In the ever-evolving landscape of kitchen appliance manufacturing, sandwich plates have emerged as a key component in the design of modern cookware. These versatile pieces are not just functional; they are also at the forefront of innovation. Here’s a look into the future of sandwich plates, with predictions and opportunities that could shape the industry.

The integration of advanced materials and manufacturing techniques has led to sandwich plates that are not only durable but also efficient. Imagine a sandwich plate that adjusts to varying heat levels, ensuring even cooking without the risk of burning. Such a technology could revolutionize the way we cook, offering convenience and precision that current models lack.

With the rise of smart home technology, the integration of sensors and connectivity into sandwich plates could become a norm. A plate that can communicate with other kitchen appliances, providing real-time cooking data and feedback, could be the next big thing. This kind of smart functionality is not just a luxury; it’s a necessity for those who want their kitchen to be an extension of their smartphone or smartwatch.

Customization is another trend that’s poised to impact the sandwich plate market. As consumers become more discerning about their kitchenware, the ability to create personalized sandwich plates could become a significant opportunity. From unique designs to specific materials, the possibilities for customization are vast, allowing manufacturers to cater to niche markets and individual preferences.

Environmental sustainability is also a growing concern, and the future of sandwich plates may see an increased focus on eco-friendly materials and manufacturing processes. Recyclable metals, biodegradable plastics, and energy-efficient production methods could become standard features, not just as a marketing tool but as a core value proposition for manufacturers.

The demand for sandwich plates that can withstand the test of time is evident. There’s a shift towards long-lasting, high-quality cookware that can be passed down through generations. This longevity not only ensures a sustainable product lifecycle but also reduces waste, which is a key factor in the sustainability equation.

One of the most intriguing opportunities lies in the intersection of health and sandwich plates. As awareness of health and wellness grows, there could be a surge in demand for sandwich plates that are non-toxic, easy to clean, and resistant to bacteria. Features like induction-friendly surfaces and ergonomic designs that reduce the risk of burns could become mainstream.

The rise of gourmet cooking at home has opened doors for sandwich plates that can handle a wide range of cooking techniques. From searing to simmering, these plates could offer multiple layers and surfaces, allowing chefs to experiment with various cooking styles without the need for multiple cookware items.

The global market for sandwich plates is also witnessing a surge in demand due to changing lifestyles and increased disposable income. In regions like Asia and South America, there’s a growing middle class that values high-quality cookware, and sandwich plates are no exception. This expansion of the market opens up new avenues for growth and diversification.

Predictions of market growth are strong, with projections indicating a steady increase in the demand for sandwich plates over the next decade. This growth is driven by factors such as urbanization, which leads to smaller living spaces where multifunctional cookware is preferred, and the rise of cooking as a leisure activity, which encourages investment in high-quality cooking tools.

In conclusion, the future of sandwich plates is bright, filled with opportunities to innovate and cater to the evolving needs of consumers. Whether it’s through technological advancements, customization, sustainability, or health-conscious features, the path forward is one of continuous improvement and innovation. As the industry adapts to new trends and consumer demands, the possibilities for success are endless.

In the realm of sandwich plate manufacturing, the significance of integrated metal stamping cannot be overstated. It’s a cornerstone technology that has revolutionized the industry, offering solutions that are not just efficient but also highly adaptable to the evolving demands of consumers. Let’s delve into the reasons why integrated metal stamping stands as a pivotal factor in the sandwich plate industry.

The precision and consistency of metal stamping processes ensure that sandwich plates are uniform in design and quality. This uniformity is crucial for brands looking to establish a reputation for reliability and durability. The technology allows for intricate patterns and designs to be transferred onto the metal, which is then formed into the sandwich plate structure. This level of detail and precision is something that manual methods struggle to achieve, making integrated metal stamping a preferred choice for manufacturers aiming to differentiate their products.

Moreover, the flexibility of metal stamping is a game-changer. It enables the creation of sandwich plates in various sizes, shapes, and thicknesses, catering to a wide range of applications. From countertop models to those designed for commercial kitchens, the versatility of metal stamping means that no matter the requirement, there’s a stamping solution that can meet it. This adaptability is particularly important in a market where customization is becoming increasingly popular.

Energy efficiency is another aspect where integrated metal stamping excels. The streamlined manufacturing process reduces energy consumption, leading to cost savings for both manufacturers and consumers. In an era where sustainability is a key concern, this efficiency not only helps businesses to reduce their carbon footprint but also aligns with the eco-conscious values of many consumers.

Case in point, a leading manufacturer of sandwich plates has leveraged integrated metal stamping to produce a line of plates that are not only aesthetically pleasing but also boast excellent heat retention properties. By using advanced stamping techniques, the company was able to design plates with unique ridges and grooves that enhance the user experience and performance.

The integration of metal stamping also facilitates the inclusion of innovative features within sandwich plates. For instance, the ability to stamp thin metal sheets allows for the embedding of sensors or heating elements, creating smart sandwich plates that can monitor cooking temperatures or even alert users to optimal cooking times. This kind of technological integration is becoming more common, as consumers seek out products that offer convenience and functionality.

The market for sandwich plates is also witnessing a shift towards materials that are not only durable but also recyclable. Integrated metal stamping plays a pivotal role in this transition, as it allows for the production of plates made from recycled metals, which can then be recycled again at the end of their lifecycle. This closed-loop system is a testament to the sustainability and environmental responsibility that integrated metal stamping brings to the table.

In terms of design, the possibilities are endless with integrated metal stamping. Manufacturers can experiment with different finishes, textures, and even incorporate antimicrobial coatings to ensure the plates are not only visually appealing but also hygienic. This attention to detail can set a brand apart in a highly competitive market.

As we look to the future, it’s clear that the sandwich plate industry is poised for growth. With an aging population that seeks convenience in their meal preparation, and a younger demographic that values health and sustainability, the demand for high-quality, innovative sandwich plates is on the rise. Integrated metal stamping will continue to be a key factor in meeting these demands, as it allows for the rapid prototyping and production of new and improved sandwich plate designs.

In conclusion, integrated metal stamping is not just a process; it’s a driving force behind the evolution of the sandwich plate industry. Its ability to produce precision parts, offer design flexibility, enhance energy efficiency, and contribute to sustainability makes it an indispensable technology. As the industry continues to evolve, those who embrace and master the art of integrated metal stamping will be well-positioned to capitalize on the opportunities that lie ahead.