Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

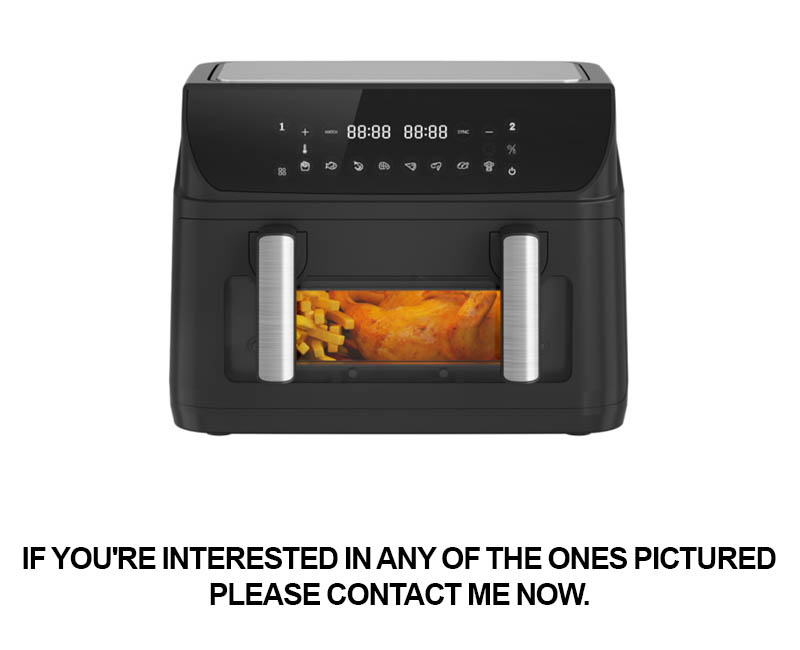

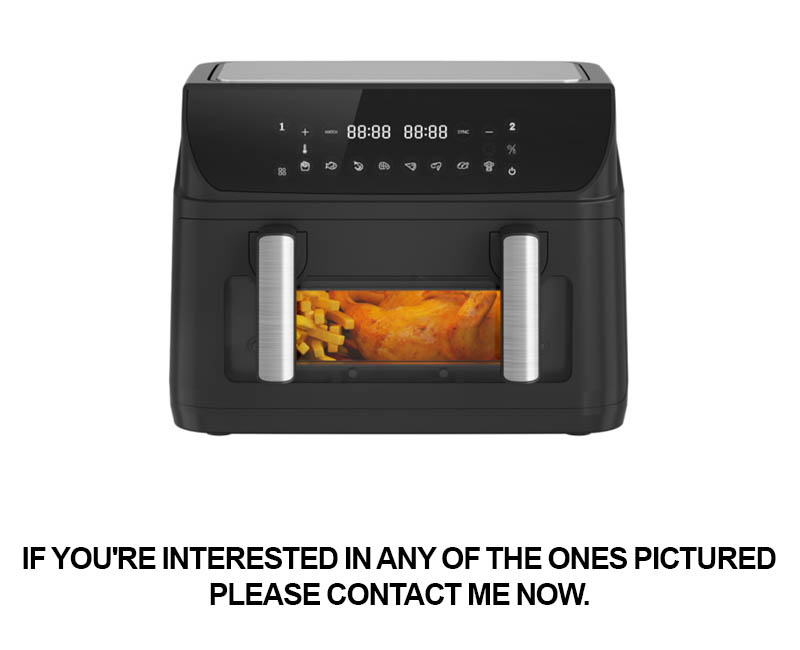

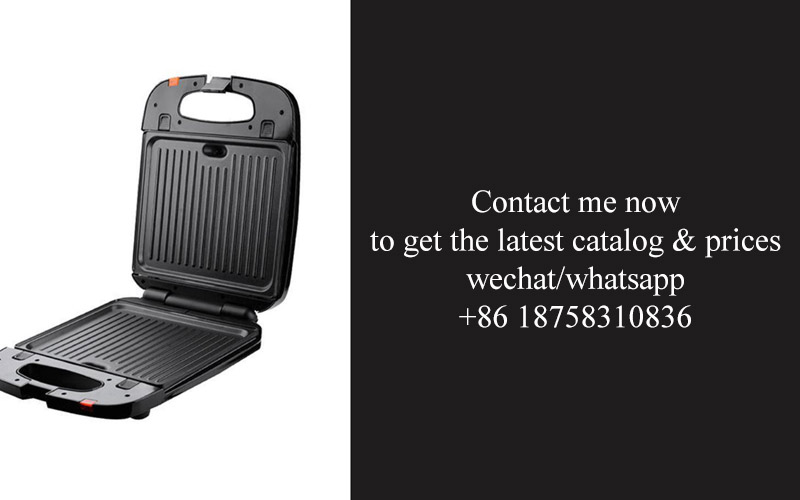

In a world where culinary innovation meets convenience, the heavy-duty sandwich press has emerged as a game-changer in the kitchen appliance market. This compact yet powerful tool has revolutionized the way we enjoy our favorite sandwiches, offering a level of craftsmanship and flavor that goes beyond the norm. As the demand for these sandwich makers continues to soar, it’s fascinating to delve into the stories behind the heavy-duty sandwich press factories that are shaping this burgeoning industry. From cutting-edge technology to global market trends, these factories are not just crafting culinary convenience—they’re redefining the art of sandwich making.

The heavy-duty sandwich press has quietly emerged as a game-changer in the kitchen appliance world, transforming the way we approach one of our favorite meals. Once a simple tool, the sandwich press has evolved into a must-have for those who take their lunch breaks seriously. Let’s delve into the fascinating journey of this kitchen gadget and how it’s become a staple in modern homes.

Once confined to the realms of greasy spoons and fast-food joints, the sandwich has now found its way into the hearts and homes of sandwich enthusiasts everywhere. The heavy-duty sandwich press, with its robust design and sturdy build, has become the go-to appliance for those looking to elevate their at-home sandwich-making experience.

The allure of the heavy-duty sandwich press lies in its ability to offer a perfect blend of texture and taste. With its high-pressure mechanism, these presses ensure that every sandwich is cooked to perfection, with a crispy outside and a tender inside. This has sparked a revolution in home cooking, making it easier than ever to enjoy restaurant-quality sandwiches without stepping outside the house.

As the demand for these sandwich presses has grown, so too has the variety of designs and features available. From classic rectangular presses to those with unique shapes and sizes, there’s something for everyone. The heavy-duty models, in particular, have gained popularity due to their durability and ability to handle even the thickest of sandwiches with ease.

One of the key factors behind the rise of the heavy-duty sandwich press is the convenience it offers. With a quick press, you can transform your ingredients into a delicious, hot sandwich in mere minutes. This has made it an ideal choice for busy individuals who need a quick and satisfying meal on the go. Whether it’s for a mid-morning snack, a lunch break, or a post-work dinner, the heavy-duty sandwich press has become a kitchen staple.

Moreover, the versatility of these presses cannot be overlooked. They are not just limited to sandwiches; many users have found creative ways to use their presses for other culinary delights. From grilled cheese to egg and vegetable sandwiches, the possibilities are endless. This adaptability has further solidified the heavy-duty sandwich press’s position as a versatile kitchen companion.

The heavy-duty sandwich press has also become a favorite among food enthusiasts and professional chefs alike. Its ability to provide consistent results time and time again is highly regarded in the culinary world. Chefs appreciate the precision and control it offers, allowing them to experiment with different ingredients and flavors with ease.

In recent years, the heavy-duty sandwich press has also gained a reputation for its durability. Made from high-quality materials, these presses are built to last, withstanding the test of time and frequent use. This has made them a wise investment for any kitchen, ensuring years of reliable service.

As the popularity of the heavy-duty sandwich press continues to soar, so does the demand for quality appliances from reputable manufacturers. The market is now flooded with a variety of brands, each offering their unique take on the classic sandwich press. This has led to a fierce competition among manufacturers, resulting in innovative designs and improved features.

In addition to the competition, the rise of social media has played a significant role in the success of the heavy-duty sandwich press. Influencers and food bloggers have been showcasing their creative sandwich recipes, often featuring the presses they use. This has not only generated buzz around the product but has also inspired countless home cooks to invest in their own sandwich presses.

The heavy-duty sandwich press has also become a symbol of culinary innovation. As manufacturers continue to push the boundaries of what is possible with this simple kitchen gadget, we can expect to see even more exciting features and designs in the future. From smart presses that can adjust cooking temperatures to those with built-in toasters, the possibilities are nearly limitless.

In conclusion, the heavy-duty sandwich press has come a long way from its humble beginnings. Its ability to provide convenience, versatility, and durability has made it a staple in modern kitchens. As the demand for high-quality, innovative appliances continues to grow, the heavy-duty sandwich press is poised to remain a dominant player in the kitchen appliance market for years to come.

In the heart of the bustling appliance industry, the heavy duty sandwich press factory stands as a beacon of innovation and technological prowess. These factories, often hidden behind sleek, modern facades, are the breeding grounds for the latest in sandwich-making technology. Here’s a closer look at what makes these factories so special.

The manufacturing process is a symphony of precision and craftsmanship, where every component is meticulously designed and engineered to perfection. From the durable stainless steel construction to the heat-conductive plates, every detail is crafted with the end-user in mind. The factories are equipped with state-of-the-art machinery that ensures each sandwich press is not just a tool but a piece of art.

Quality control is paramount in these facilities, with stringent checks at every stage of production. Workers are trained to identify even the smallest of defects, ensuring that only the highest-quality sandwich presses leave the factory floor. This commitment to quality is what sets these factories apart, and it’s what guarantees that each product will deliver consistent performance for years to come.

Innovation is not just a buzzword at these factories; it’s a way of life. Designers and engineers are constantly pushing the boundaries, experimenting with new materials and techniques to create the ultimate sandwich-making experience. The result is a range of heavy duty sandwich presses that cater to a variety of culinary preferences, from crispy, golden-brown sandwiches to those with perfectly melted cheese and juicy fillings.

Safety is another cornerstone of these factories. They adhere to the strictest safety standards, both for their employees and for the end-users. From the ergonomic handles that make the presses easy to use to the temperature controls that prevent overheating, these devices are designed with safety at the forefront. This attention to detail not only ensures user satisfaction but also helps to build a brand reputation that consumers can trust.

The manufacturing process itself is a testament to the factory’s dedication to excellence. It starts with raw materials, sourced from the finest suppliers around the world. These materials are then processed and transformed into the components that make up the sandwich presses. The assembly line is a marvel of efficiency, with each press being hand-checked and calibrated before being packaged for shipping.

The factories also prioritize sustainability. They are committed to reducing their environmental footprint by using energy-efficient machinery and recycling waste materials whenever possible. This eco-conscious approach is not only good for the planet but also resonates with consumers who are increasingly looking for sustainable options in their purchases.

Training is an integral part of the factory’s operations. Employees are trained not only in the technical aspects of manufacturing but also in the importance of customer satisfaction and the values that the brand represents. This holistic approach to training helps to create a workforce that is both skilled and dedicated to producing the best heavy duty sandwich presses on the market.

As the demand for these appliances grows, the factories are expanding their capabilities to meet the increasing demand. New technologies are being introduced to streamline production and improve efficiency. This expansion doesn’t just mean more sandwich presses; it also means more jobs and more opportunities for growth within the industry.

The heavy duty sandwich press factory is a dynamic and ever-evolving entity. It’s a place where innovation meets functionality, where quality is king, and where safety and sustainability are not just buzzwords but a lived reality. It’s a hub of creativity and dedication, constantly striving to deliver products that not only make great sandwiches but also enhance the lives of those who use them.

In the realm of culinary craftsmanship, the sandwich has long been a staple, a simple yet versatile canvas for creativity. However, it’s not just the ingredients that make a sandwich special; it’s the method of preparation that can truly elevate the experience. Enter the heavy-duty sandwich press, a tool that has been quietly revolutionizing the art of sandwich making.

The heavy-duty sandwich press is not just a gadget; it’s a game-changer. Its robust design and powerful mechanism ensure that every sandwich is cooked to perfection, with a golden-brown crust and a juicy, melty interior. The pressure applied by the press helps to seal in the flavors, locking them into the bread for a more satisfying bite.

Imagine the classic BLT, with its layers of crisp bacon, tangy lettuce, and creamy tomato, all compressed into a tight, flavorful sandwich. The heavy-duty press can take this simple delight to new heights, ensuring that each component is melded together with precision. The result is a sandwich that’s not just a meal, but an experience, with each bite offering a symphony of textures and tastes.

But it’s not just about the classic fare. The heavy-duty press is also a canvas for culinary adventurers. It can handle a variety of breads, from the soft, pillowy brioche to the hearty multigrain, and even the unconventional, like sourdough or bagels. The press’s even heat distribution means that no matter the bread, the outcome is consistently delicious.

One of the most delightful aspects of using a heavy-duty sandwich press is the ability to customize. You can layer your ingredients with creativity, adding in melted cheese, a sprinkle of herbs, or even a dollop of avocado. The press ensures that each layer is cooked uniformly, so you end up with a sandwich that’s as visually appealing as it is tasty.

The press also plays a crucial role in the texture of the sandwich. The pressure helps to create a perfect crust, one that’s crispy on the outside yet tender on the inside. It’s this contrast that makes a sandwich not just a meal, but a work of art. The art of sandwich making becomes a tactile experience, with each sandwich telling a story of its own.

Moreover, the heavy-duty press is not just for sandwiches. It can be used to cook other items like paninis, grilled cheese, or even to press out excess moisture from fresh herbs or spices. Its versatility makes it a must-have for any kitchen enthusiast.

The process itself is almost meditative. As you place your carefully selected ingredients between the heated plates of the press, you can’t help but feel a sense of anticipation. The gentle hiss as the press closes and the smell of the sandwich beginning to cook fills the air, it’s a moment of preparation and anticipation.

The final product is a testament to the art of sandwich making. The heavy-duty press has taken your raw ingredients and transformed them into something extraordinary. Each sandwich is a testament to the power of culinary technique, a reminder that sometimes, the simplest tools can create the most profound culinary experiences.

In essence, the heavy-duty sandwich press is more than just a kitchen appliance; it’s a tool that allows for the expression of culinary creativity. It’s a way to take a simple meal and turn it into an event, a moment of joy that comes from the satisfaction of crafting something delicious with your own hands. The press may be a simple tool, but in the hands of a sandwich enthusiast, it’s a masterpiece in the making.

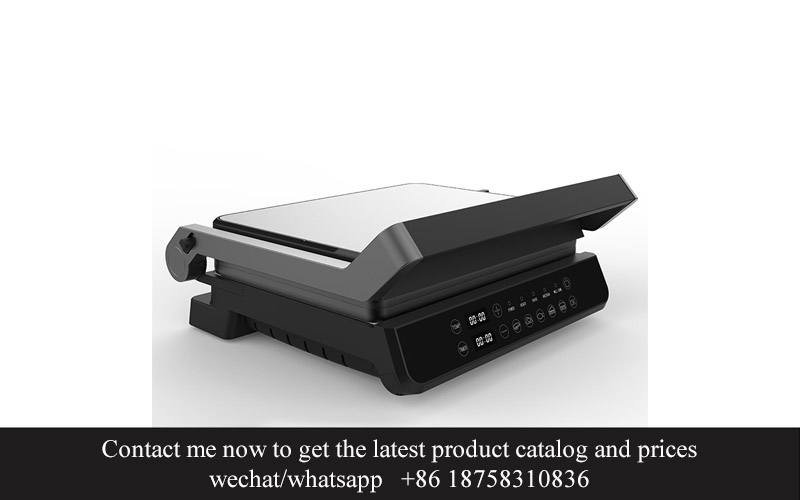

In the realm of kitchen appliances, the heavy duty sandwich press has emerged as a game-changer, transforming the way we savor our favorite sandwiches. When it comes to selecting a high-quality sandwich press from a reputable factory, there are several key features to consider that can elevate your sandwich-making experience to a whole new level.

Durability is paramount in a heavy duty sandwich press. Look for models made from heavy-gauge stainless steel, which not only ensures longevity but also provides even heat distribution. The press should be robust enough to handle thick sandwiches without bending or warping over time.

Thermal conductivity is crucial for achieving that perfect, golden-brown crust on your sandwich. A sandwich press with a high-quality, thick heating element will guarantee consistent heat, allowing you to achieve the ideal texture and color every time.

Non-stick surfaces are a must-have feature in a sandwich press. This not only makes cleanup a breeze but also ensures that your sandwiches won’t stick to the press, preserving their integrity and flavor.

A sturdy handle is essential for safely opening and closing the press. The handle should be heat-resistant and firmly attached to the device, allowing for easy operation without the risk of burns or slipping.

When it comes to size, consider the capacity of the sandwich press. A larger press can accommodate thicker sandwiches and even double-deckers, while a smaller model might be more suitable for single or thin sandwiches. The design should also allow for easy insertion and removal of the sandwiches.

The sandwich press should have adjustable pressure settings. This feature lets you control the amount of pressure applied to the sandwich, which can influence the crispness of the bread and the juiciness of the fillings. Some models even have a locking mechanism to ensure consistent pressure throughout the cooking process.

A clear, easy-to-read temperature control is essential for precision cooking. Look for a sandwich press with a digital display or a temperature gauge that allows you to set and monitor the heat accurately.

Safety features should not be overlooked. A sandwich press with a cool-to-the-touch exterior is important, as is a locking lid to prevent accidental closures. Some models even come with an automatic shut-off feature that turns off the press once the cooking time has elapsed, reducing the risk of burns.

In terms of design, a sleek and modern look can add a touch of style to your kitchen. However, functionality should always come first. The press should have a compact design that won’t take up too much counter space, yet be large enough to handle the sandwiches you enjoy making.

A heavy duty sandwich press from a reputable factory will often come with a warranty, providing peace of mind and protection for your investment. Check the warranty terms to ensure that they cover manufacturing defects and potential issues that may arise from normal use.

Additional features can enhance your sandwich-making experience. For instance, some presses include a drip tray to catch any excess moisture, while others offer a removable base for easy cleaning. A built-in thermometer can also be a handy feature for those who like to experiment with different types of bread and fillings.

Lastly, consider the brand reputation and customer reviews. A sandwich press from a trusted manufacturer is more likely to meet your expectations in terms of quality, performance, and customer satisfaction. Reading what other users have to say can provide valuable insights into the real-life performance of the product.

By focusing on these features when selecting a heavy duty sandwich press, you can ensure that your sandwich-making experience is not only enjoyable but also results in perfectly cooked sandwiches that are a delight to eat.

The surge in popularity of heavy-duty sandwich presses has been nothing short of a phenomenon. There’s an undeniable allure to these robust kitchen gadgets that seems to be resonating with home cooks and culinary enthusiasts alike. Let’s delve into the reasons behind this growing trend.

One might ask, “What sets heavy-duty sandwich presses apart from their lighter counterparts?” The answer lies in the attention to detail and the functionalities that these presses offer. They’re designed with durability and precision in mind, ensuring that every sandwich comes out with that perfect golden-brown crust and perfectly melted cheese.

The market is buzzing with convenience-driven innovations, and the heavy-duty sandwich press is a testament to this. People are gravitating towards appliances that save time and effort without compromising on quality. These presses can handle thick sandwiches with ease, locking in flavors and textures like no other kitchen tool can.

Health consciousness is also a significant factor. As more individuals become aware of the calorie counts in fast food and fast-casual dining options, they’re turning to homemade sandwiches as a healthier alternative. The heavy-duty press allows for customization, enabling sandwich enthusiasts to craft their perfect meal with fresh ingredients, thus promoting a balanced diet.

The rise of social media has played a pivotal role in the popularity of these sandwich presses. With platforms like Instagram and TikTok, the culinary community has shared countless “sandwich-making masterpieces.” The visual appeal of a perfectly pressed sandwich with visible layers of ingredients is irresistible, and it’s driving the market trends.

Moreover, the convenience factor isn’t just about saving time in the kitchen; it’s about the ease of cleanup. Many heavy-duty sandwich presses are designed with non-stick surfaces that make release and cleanup a breeze. This ease of maintenance appeals to busy individuals who don’t want to spend their valuable time on dishwashing.

Customization is another key driver. From classic ham and cheese to gourmet creations with avocado and smoked salmon, the heavy-duty sandwich press can accommodate a variety of recipes. It’s like having a professional-grade kitchen appliance right at home, allowing for experimentation and creativity without the high price tag.

Eco-consciousness is on the rise, and the heavy-duty sandwich press fits right into this mindset. By making homemade sandwiches more appealing, these presses contribute to reducing single-use packaging and plastic waste, which is a win for the environment.

Safety features are also becoming a selling point. With adjustable temperature controls and secure locking mechanisms, modern heavy-duty sandwich presses ensure that the cooking process is both safe and effective. The peace of mind that comes with these features is something that many consumers are willing to pay extra for.

As we look at the market trends, it’s clear that the convenience, health benefits, and versatility of heavy-duty sandwich presses are the reasons behind their popularity. But it doesn’t stop there. The evolving landscape of kitchen appliances is seeing an increase in smart features, and the heavy-duty sandwich press isn’t immune to these advancements.

Some presses are now coming equipped with built-in timers and temperature indicators, providing users with the perfect cooking time for each sandwich. Others have integrated LED lights to ensure that the cooking surface is evenly toasted. These features not only enhance the experience but also cater to the growing preference for tech-savvy kitchen gadgets.

Lastly, the competitive pricing of these sandwich presses cannot be overlooked. While some high-end models might cost a pretty penny, there’s a wide range of affordable options available that offer exceptional performance. This accessibility is a key factor in their widespread appeal.

In conclusion, the rise of the heavy-duty sandwich press in the market is a reflection of changing consumer preferences and the evolving kitchen landscape. As we continue to see advancements in design, features, and health consciousness, it’s no surprise that these presses are becoming a staple in many homes. The days of settling for a simple grilled cheese are long gone; now, everyone can be a sandwich artist in their own kitchen.

In recent years, the demand for heavy-duty sandwich presses has surged, transforming the way we savor this classic comfort food. These robust appliances have not only become a staple in professional kitchens but have also found their way into the hearts of home chefs. Let’s delve into the profiles of the individuals and reasons behind the surge in heavy-duty sandwich press purchases.

The Culinary Enthusiast: From Hobbyist to Hobby ChefOne group driving the popularity of heavy-duty sandwich presses is the culinary enthusiast. These are individuals who love to cook and experiment with flavors. Whether they are seasoned gourmands or novices looking to improve their culinary skills, the ability to create perfectly toasted, evenly seasoned sandwiches is a dream come true. The precision and consistency that a heavy-duty press offers are perfect for this crowd, who value quality over quantity.

The Busy Professional: Efficiency in Every BiteThe modern lifestyle leaves many professionals with little time for meal prep. Heavy-duty sandwich presses provide a quick and easy solution to this conundrum. The convenience of being able to prepare a delicious sandwich in mere minutes is attractive to those who are always on the go. The ability to customize their meals with different fillings and toasting preferences is an added bonus, making the sandwich press not just a kitchen gadget but a time-saving tool.

The Home Baker: Perfecting the Art of Bread CraftingBread enthusiasts, especially those who love to bake their own bread, see the heavy-duty sandwich press as a must-have. The press not only ensures their homemade loaves are perfectly toasted but also allows for the even distribution of butter or spreads. It’s like having an extra set of hands to ensure that each slice is as delicious as the last, which is incredibly satisfying for anyone who takes pride in their bread-making skills.

The Health-Conscious Consumer: Nutrient-Rich Meals Without the GuiltThe health-conscious market has also taken notice of heavy-duty sandwich presses. With an increasing awareness of nutrition and a desire to avoid processed foods, these presses enable individuals to control the ingredients that go into their sandwiches. The ability to use fresh, whole-grain bread and healthy toppings means they can enjoy a satisfying, nutritious meal without compromising on taste or quality.

The Entrepreneurial Chef: A Professional Edge for the Home ChefFor those looking to take their culinary skills to the next level, a heavy-duty sandwich press is an essential tool. It’s not uncommon for home chefs to dream of starting their own food business. These presses can help aspiring entrepreneurs develop their unique sandwich recipes and offer a consistent product to customers. It’s a small step into the world of entrepreneurship that can lead to big dreams.

The Social Gathering Enabler: Creating Memories with Every PressSocial gatherings often revolve around food, and heavy-duty sandwich presses can be the centerpiece of these events. They are not just a kitchen appliance but a way to bring people together and create memories. From potlucks to family gatherings, the ability to make sandwiches on the spot can make a significant difference in the enjoyment of the meal and the atmosphere.

The Gadget Collector: Adding to the Kitchen CollectionFor some, the purchase of a heavy-duty sandwich press is a matter of collecting kitchen gadgets. There’s a certain allure to owning a tool that combines functionality with design. The press is often seen as a unique and practical addition to a gadget collection, appealing to those who appreciate the art of cooking and the joy of collecting.

In conclusion, the surge in popularity of heavy-duty sandwich presses can be attributed to a diverse group of consumers, each with their own motivations and preferences. From the time-strapped professional to the health-conscious consumer, and from the aspiring chef to the gadget enthusiast, these presses are a versatile and beloved addition to any kitchen. Whether for personal use or to start a new venture, the heavy-duty sandwich press has found its place in the hearts and minds of sandwich lovers everywhere.

In the world of heavy-duty sandwich presses, technology has played a pivotal role in shaping the industry’s evolution. Here’s a look at how technology has influenced this niche market.

Materials and ConstructionModern heavy-duty sandwich presses are engineered with high-quality materials that not only enhance durability but also ensure even heating and pressing. Stainless steel is a common choice for its resistance to corrosion and ability to maintain temperature. Advanced construction techniques, like laser-cutting and CNC machining, have allowed for the creation of precise parts that contribute to the superior performance of these presses.

Smart Heating ElementsThe heart of any sandwich press lies in its heating element. Over time, technology has introduced smart heating elements that provide precise temperature control. These elements can often be adjusted to cater to different types of bread and fillings, ensuring that every sandwich is cooked to perfection. Some models even feature non-stick surfaces that reduce the need for butter or oil, making clean-up easier and the process healthier.

User-Friendly FeaturesTechnology has made heavy-duty sandwich presses more user-friendly than ever. Features like digital displays allow for easy temperature adjustments, while auto-shutoff and keep-warm functions offer convenience and safety. Some presses even have timers and programmable settings, making it possible to prepare complex sandwiches with minimal effort.

Automated Pressing MechanismsGone are the days when pressing a sandwich required brute force. Today’s heavy-duty sandwich presses come with automated pressing mechanisms that apply even pressure, eliminating the guesswork and inconsistency often found with manual presses. This not only guarantees a professional-looking finish but also helps maintain the integrity of the sandwich’s filling.

Safety InnovationsSafety is a top priority in kitchen appliances, and the heavy-duty sandwich press industry is no exception. Modern presses often incorporate safety features like cool-to-the-touch exteriors and non-slip bases to prevent accidents. Additionally, advanced heat sensors can detect when the press is too hot to handle, reducing the risk of burns.

Customization and PersonalizationTechnology has opened the door to customization in the sandwich press market. Users can now find presses that offer adjustable press force, allowing for the perfect level of compression depending on personal preference. Some models even feature removable plates for easy cleaning and the option to use them as graters or pizza presses.

Integration with Smart Kitchen DevicesThe rise of the smart kitchen has seen heavy-duty sandwich presses integrate with other smart kitchen devices. Imagine a scenario where your sandwich press is controlled through a smartphone app, allowing you to set it and walk away, returning to a perfectly toasted sandwich. This kind of connectivity is not just convenient but also indicative of the technological advancements driving the industry.

Innovation in DesignThe design of heavy-duty sandwich presses has been revolutionized by technology. Sleek, modern aesthetics are now a staple, with compact designs that save space on countertops. Some presses even come with features like integrated drip trays to prevent messes and easy-to-use controls that are as stylish as they are functional.

Maintenance and CleaningWith the integration of advanced materials and non-stick surfaces, the maintenance and cleaning process for heavy-duty sandwich presses have become simpler. Modern presses are designed to be easily disassembled for cleaning, and many come with self-cleaning features that can be initiated with the press of a button.

Customer Support and WarrantyTechnology has also extended to customer support and warranty services. Factories producing heavy-duty sandwich presses often offer comprehensive online support and detailed warranty information, ensuring that customers feel confident in their purchase and are well-supported if issues arise.

In conclusion, the role of technology in the heavy-duty sandwich press industry is undeniable. It has not only improved the functionality and convenience of these appliances but has also raised the bar for what customers expect from kitchen technology. As the industry continues to evolve, it’s clear that technology will remain at the forefront, shaping the future of sandwich making at home.

In the ever-evolving landscape of kitchen appliances, sustainability and energy efficiency have become paramount concerns for manufacturers. Sandwich presses, once a simple tool for crafting the perfect grilled sandwich, are now being reimagined with eco-friendly features. Here’s how sustainability is becoming a new standard in sandwich press manufacturing.

The shift towards sustainability starts with the materials used in the construction of heavy-duty sandwich presses. Traditional presses might have been made from metals that required significant energy to produce and were not easily recyclable. However, modern factories are now opting for materials like stainless steel, which are not only durable but also more environmentally friendly. These metals are often recycled and can be reused in the production process, reducing the carbon footprint.

Energy efficiency is another critical aspect that has seen a transformation in sandwich press manufacturing. Older models might have been powered by electricity, but the newer heavy-duty presses are designed to minimize energy consumption. Smart features such as automatic shut-off after a certain period of inactivity help conserve energy. Some presses even come with adjustable heat settings, allowing users to save energy by not heating the appliance to the maximum temperature when a lower setting will suffice.

Innovation in insulation technology has also played a significant role in making sandwich presses more sustainable. High-quality insulation materials are used to retain heat, ensuring that the sandwich is cooked to perfection without the need for excessive energy. This not only saves energy but also reduces the overall heat output, which is beneficial for the environment.

The design of sandwich presses has also been refined to be more user-friendly and sustainable. Many modern presses come with non-stick surfaces that require less oil or butter to prevent sticking, reducing waste and the need for additional cleaning products. Additionally, the compact and space-saving designs of these presses mean they take up less room in kitchens, which can be a more sustainable use of space.

Another aspect of sustainability in sandwich press manufacturing is the focus on longevity. High-quality components and robust construction ensure that these appliances last longer, reducing the need for frequent replacements. This not only saves money for consumers but also reduces the amount of e-waste that ends up in landfills.

Corporate social responsibility (CSR) initiatives are also becoming a part of the sandwich press manufacturing process. Factories are increasingly adopting green practices, such as using renewable energy sources for their operations and ensuring that waste is properly managed. Some are even participating in recycling programs to repurpose materials from old appliances into new ones.

The packaging of sandwich presses is also being re-evaluated for sustainability. Instead of using single-use plastics, manufacturers are now opting for recyclable or biodegradable materials. This not only reduces waste but also sends a strong message to consumers about the brand’s commitment to environmental responsibility.

Lastly, the integration of smart technology in sandwich presses is not just about convenience; it’s also about sustainability. Smart features allow users to monitor and control their appliances remotely, ensuring that they are only in use when necessary. This not only saves energy but also educates consumers about the importance of energy conservation.

In conclusion, the sandwich press industry is embracing sustainability and energy efficiency as key components of their manufacturing process. From the materials used to the design, technology, and corporate practices, every aspect is being scrutinized and improved to create a more eco-friendly product. As consumers become more environmentally conscious, these sustainable practices are likely to become the norm, not the exception, in sandwich press manufacturing.

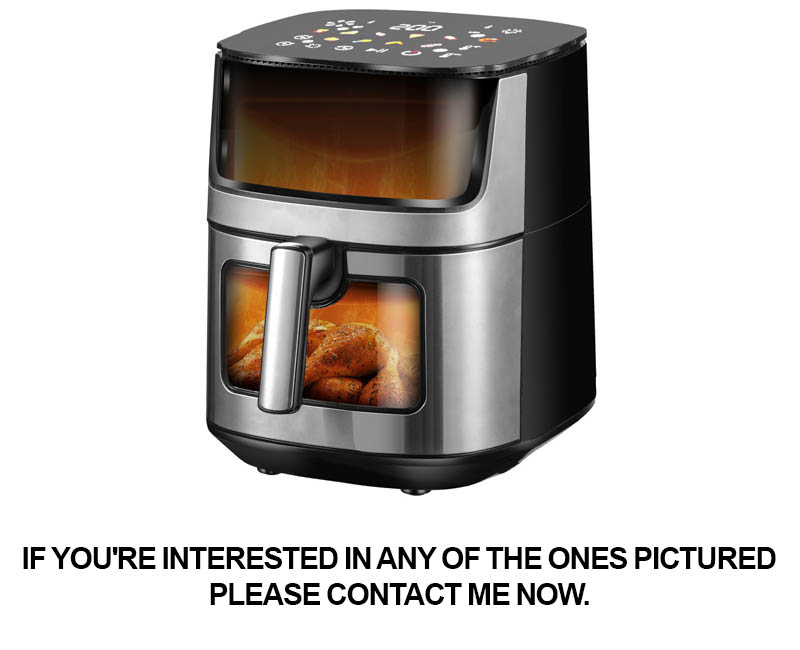

In the world of kitchen appliances, the heavy-duty sandwich press has emerged as a versatile and sought-after tool. Its global reach is expanding rapidly, and it’s not just a trend—it’s a revolution in the way people enjoy their sandwiches. Let’s delve into how these sandwich makers are capturing international markets.

The design of heavy-duty sandwich presses has evolved to cater to diverse tastes and preferences across the globe. From sleek, modern models with digital controls to classic, sturdy designs, these presses are tailored to suit various consumer needs. This adaptability has been key in their international success.

International markets are often characterized by unique culinary traditions, and the heavy-duty sandwich press has found ways to integrate into these cultures. For instance, in Europe, the press has been embraced for its ability to create the perfect panini, while in Asia, it’s been adopted to make Japanese-style grilled sandwiches. This cultural integration has not only helped the presses gain popularity but has also inspired local chefs and home cooks to experiment with new flavors and combinations.

The global reach of heavy-duty sandwich presses is also due to the ease of use and maintenance they offer. These appliances are designed to be user-friendly, with features like non-stick surfaces and removable plates that make cleaning a breeze. This convenience is particularly appealing to busy professionals and families, who seek efficient kitchen solutions.

E-commerce platforms have played a significant role in the international success of heavy-duty sandwich presses. With online shopping becoming increasingly popular worldwide, these presses are just a click away for consumers in every corner of the globe. Online marketplaces have made it possible for manufacturers to reach a vast audience without the need for extensive physical distribution networks.

Another factor contributing to the global appeal of heavy-duty sandwich presses is the rise of food blogs and social media influencers. These platforms have become powerful tools for product promotion, and many have endorsed the sandwich presses for their ability to create restaurant-quality sandwiches at home. The viral nature of these endorsements has helped spread the word about the benefits of these appliances far and wide.

In the international market, heavy-duty sandwich presses come in a variety of sizes and power outputs to accommodate different cooking preferences and kitchen spaces. For instance, smaller models are perfect for apartment dwellers with limited counter space, while larger, more powerful presses are ideal for commercial kitchens or those who enjoy hosting large gatherings.

The environmental consciousness of consumers has also played a role in the success of heavy-duty sandwich presses. As more people look for eco-friendly appliances, these presses have been designed with sustainability in mind. From energy-efficient motors to durable materials, these appliances are not only functional but also environmentally responsible.

Additionally, the versatility of heavy-duty sandwich presses has been a hit with international consumers. These presses can be used to make not only sandwiches but also wraps, pizzas, and even tofu scrambles. This versatility opens up a world of culinary possibilities, making them a must-have for food enthusiasts around the globe.

Lastly, the global reach of heavy-duty sandwich presses is a testament to the power of innovation. Manufacturers have continuously sought to improve their designs, incorporating the latest technology and materials to enhance the user experience. This commitment to innovation ensures that the heavy-duty sandwich press remains a staple in international kitchens for years to come.

In conclusion, the global reach of heavy-duty sandwich presses is a result of their design, functionality, and adaptability to diverse cultural tastes. With the help of e-commerce, social media, and environmental consciousness, these sandwich makers are not just taking over international markets—they’re becoming a beloved kitchen companion across the globe.

In the world of kitchen appliances, heavy duty sandwich presses have emerged as a game-changer, and their success stories are becoming increasingly prominent. Let’s delve into some of these tales of triumph from the factories that craft these innovative devices.

The story of the Heavy Duty Sandwich Press Factory in Chicago began with a simple vision: to create a sandwich press that could withstand the demands of busy cafes and restaurants. Their first model, the “Chicago Classic,” was a hit, known for its robust build and even heating capabilities. The factory’s dedication to quality and innovation led to a steady stream of satisfied customers, each with their own success story.

One such story comes from a small café in Seattle, where the owner, Sarah, was struggling to maintain consistent sandwich quality. She invested in a Heavy Duty Sandwich Press and noticed an immediate improvement. Not only did the sandwiches have a perfect golden-brown crust, but the process was also faster and more efficient. Sarah’s café became the talk of the town, and her success can be attributed to the reliable performance of the sandwich press.

In Italy, a family-run bakery faced a challenge that was all too common in the food industry: maintaining the integrity of their sandwiches during the busy lunch rush. The bakery manager, Giuseppe, decided to try a Heavy Duty Sandwich Press from a local factory. The results were transformative. The press’s ability to evenly distribute heat meant that each sandwich was cooked to perfection, with a satisfying crunch and a melting cheese that kept customers coming back for more.

Another success story unfolds in Tokyo, where a trendy café was looking to differentiate itself in a competitive market. They chose a Heavy Duty Sandwich Press that not only delivered high-quality sandwiches but also had a sleek, modern design. The press became a centerpiece of the café, drawing in customers who were intrigued by the unique cooking process. The café’s reputation for exceptional sandwiches and innovative use of the press grew, leading to a loyal customer base.

The Heavy Duty Sandwich Press Factory in Germany has also seen its share of success stories. One of their presses was installed in a bustling street food vendor’s cart, where it quickly became the talk of the town. The vendor, Alex, was able to serve up delicious, freshly pressed sandwiches in a matter of minutes, turning a simple street food cart into a must-visit spot for hungry passersby.

In the United States, a food truck owner named Emily was looking for a way to elevate her menu. She discovered the Heavy Duty Sandwich Press and decided to give it a try. The press’s ability to cook a variety of sandwiches, from classic ham and cheese to gourmet avocado and smoked salmon, allowed Emily to offer a diverse selection that kept her customers satisfied. The food truck’s popularity soared, and Emily’s success was a testament to the versatility of the sandwich press.

These stories are just a few examples of how heavy duty sandwich presses are changing the landscape of the food industry. From busy cafes to bustling bakeries, these presses are not just tools for cooking; they are catalysts for business growth and customer satisfaction. The factories that produce these presses are not just manufacturing appliances; they are creating experiences that resonate with consumers around the world. Each success story is a testament to the power of innovation and the enduring appeal of a perfectly pressed sandwich.

In the ever-evolving world of kitchen appliances, the heavy duty sandwich press has emerged as a game-changer, redefining the way we savor our meals. As we delve into the future prospects of sandwich press technology, it’s clear that innovation is on the horizon, promising to bring about the next big thing in the industry.

The integration of smart technology has already begun to reshape the landscape, offering users a level of convenience and control that was once unimaginable. Imagine a sandwich press that not only ensures the perfect crunch but also adjusts its heat settings based on the type of bread or filling you’ve chosen. This level of customization is not just a novelty; it’s a testament to the strides being made in the industry.

One cannot overlook the importance of sustainability in the manufacturing process. As environmental concerns grow, the heavy duty sandwich press industry is responding with eco-friendly materials and energy-efficient designs. These changes are not just about reducing the carbon footprint; they are about setting a new standard for what it means to be a responsible manufacturer.

The rise of health-conscious consumers has also played a significant role in shaping the future of sandwich press technology. We’re seeing a surge in demand for models that not only cook sandwiches but also offer features like non-stick surfaces and removable components for easy cleaning, making them a healthier option for those looking to minimize the use of oils and fats.

The global market for heavy duty sandwich presses is expanding rapidly, with no signs of slowing down. This international growth is being driven by a variety of factors, including the growing popularity of fast-casual dining, the desire for convenience, and the increasing number of people who enjoy crafting their own meals at home.

In the United States, for instance, the sandwich press has become a staple in many households, thanks to the rise of gourmet sandwich shops and the convenience of at-home cooking. Meanwhile, in Europe, the emphasis on artisanal food preparation has created a niche market for high-quality, heavy duty sandwich presses.

Asia, on the other hand, is a region where innovation is key. The rapid urbanization and the growing middle class have led to a demand for kitchen appliances that not only perform well but also look stylish. This has spurred the development of sandwich presses that are not only functional but also serve as a statement piece in modern kitchens.

As we look to the future, one cannot ignore the potential of augmented reality (AR) and virtual reality (VR) in the sandwich press industry. Imagine being able to see how your sandwich will turn out before you even press it, or being guided through the cooking process by an AR coach. These technologies have the power to revolutionize the way we interact with our kitchen appliances.

The rise of social media has also had a profound impact on the sandwich press industry. Influencers and home chefs are constantly experimenting with new recipes and tools, and the heavy duty sandwich press is no exception. The ability to share these experiences with a global audience has not only increased the visibility of these products but has also inspired a new wave of innovation.

Success stories from heavy duty sandwich press factories around the world are becoming more and more diverse. From a small startup in Germany that specializes in handcrafted presses to a large-scale manufacturer in China that has developed a line of smart sandwich makers, these stories are a testament to the industry’s dynamism.

In Germany, for example, a family-owned factory has been perfecting the art of sandwich pressing for generations. Their presses are known for their precision and durability, and they’ve managed to carve out a niche market for themselves by focusing on high-quality materials and timeless design.

In China, a factory has leveraged the country’s advanced manufacturing capabilities to create a line of sandwich presses that combine traditional craftsmanship with modern technology. Their presses are not only powerful and efficient but also come with a range of smart features that cater to the needs of today’s consumers.

As we anticipate the next big thing in sandwich press technology, it’s clear that the industry is poised for continued growth and innovation. The key will be in balancing the latest technological advancements with the needs and desires of consumers. Whether it’s through smart features, sustainable designs, or the integration of new technologies like AR and VR, the future of the heavy duty sandwich press looks bright and promising.

In the ever-evolving landscape of kitchen appliances, the heavy duty sandwich press has emerged as a game-changer, redefining the way we savor our favorite sandwiches. These presses, once a niche product, have now become a staple in many homes and commercial kitchens alike. The factory that produces these innovative devices has not only crafted a tool for culinary convenience but has also paved the way for a new era of sandwich-making.

The design of a heavy duty sandwich press is a blend of functionality and aesthetics. These presses are built to withstand the rigors of frequent use, with sturdy materials and durable construction. The non-stick surfaces ensure that each sandwich is perfectly cooked without any unwanted sticking, while the even heat distribution guarantees a golden-brown crust and a juicy, tender interior. The adjustable pressure settings allow for a variety of sandwich styles, from the classic pressed club to the gourmet grilled cheese.

The rise in popularity of heavy duty sandwich presses can be attributed to several factors. For one, the convenience they offer is unparalleled. Who wouldn’t appreciate a quick, hassle-free way to make a delicious sandwich at home or in a commercial setting? The portability of these presses means they can be easily transported, making them a favorite among campers, travelers, and those with limited kitchen space.

Moreover, the versatility of heavy duty sandwich presses is a major draw. They can handle a wide range of ingredients, from the simplest of bread and cheese to more complex fillings like avocado, smoked salmon, and roasted vegetables. This adaptability has made them a favorite among sandwich enthusiasts and culinary professionals alike.

Consumer insights into who is buying these sandwich makers reveal a diverse group of individuals. Home chefs and foodies are drawn to the ability to create gourmet sandwiches at home, while busy professionals appreciate the convenience of a quick, healthy meal. Students and young adults often seek out sandwich presses for their compact size and ease of use. Even in commercial settings, from cafes to hotels, the demand for these presses is high due to their ability to serve a large number of customers efficiently.

Technology has played a pivotal role in the evolution of the heavy duty sandwich press industry. Advanced heating elements ensure consistent performance, while innovative materials reduce the weight and increase the longevity of the presses. Smart features, such as digital temperature controls and programmable settings, have become standard, allowing users to customize their sandwich-making experience. The integration of Bluetooth technology even allows for remote control and monitoring, showcasing how technology has become an integral part of modern kitchen appliances.

Sustainability and energy efficiency have also become key considerations in sandwich press manufacturing. Eco-friendly materials are used to reduce the carbon footprint, and energy-saving designs ensure that these presses consume less power without compromising on performance. This shift towards sustainability is not only beneficial for the environment but also resonates with consumers who are increasingly conscious of their ecological impact.

The global reach of heavy duty sandwich presses is expanding rapidly. These appliances are not just popular in Western countries; they are gaining traction in Asia, South America, and Africa. The simplicity of the concept, combined with the universal appeal of sandwiches, has made these presses a hit across cultures. Importers and distributors are capitalizing on this international demand, bringing the joy of perfectly pressed sandwiches to homes and restaurants worldwide.

Several success stories from heavy duty sandwich press factories highlight the industry’s growth and innovation. One such story is the case of a small, family-owned factory that started by producing sandwich presses for local markets. Through relentless innovation and a commitment to quality, they have now become a global leader in the industry, exporting their products to over 50 countries. Their story is a testament to the power of dedication and the potential of a simple yet effective kitchen gadget.

As we look to the future, the prospects for the heavy duty sandwich press industry are bright. The next big thing in sandwich press technology may involve even more advanced features, such as integrated food storage solutions, smart recipes, and interactive cooking guides. The industry is also likely to see a greater emphasis on customization, with users being able to choose from a variety of press shapes, sizes, and materials to suit their personal preferences.

In conclusion, the heavy duty sandwich press factory has not only crafted a tool for culinary convenience but has also revolutionized the way we think about sandwiches. From the humble origins of a simple kitchen gadget to a global phenomenon, these presses have proven that sometimes, the most effective innovations come in the form of a well-made sandwich.