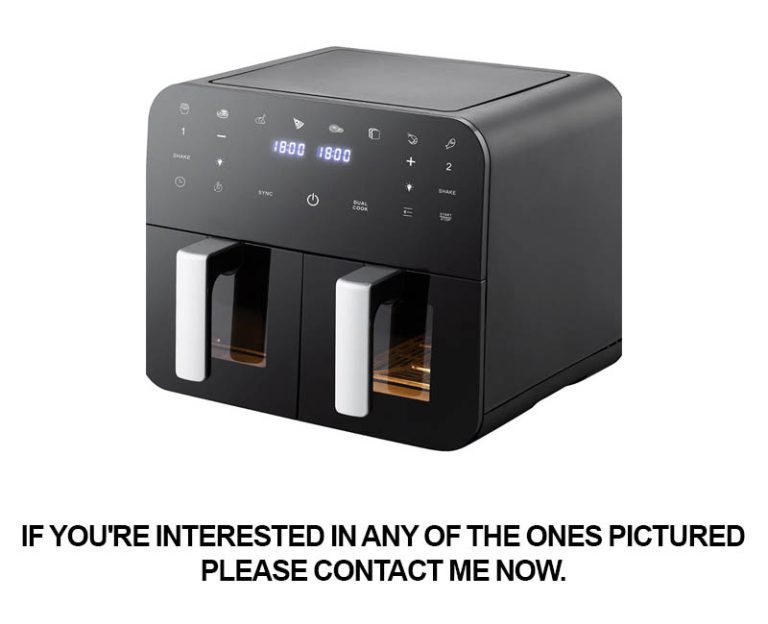

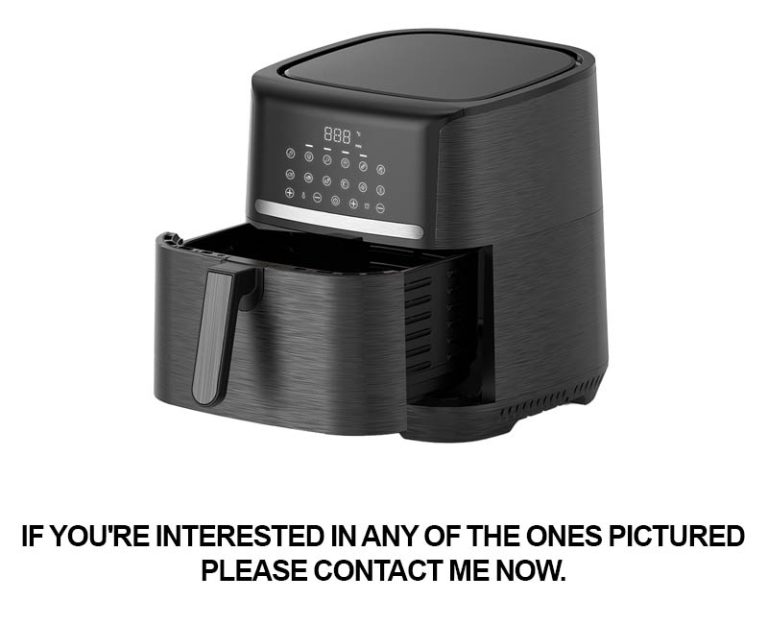

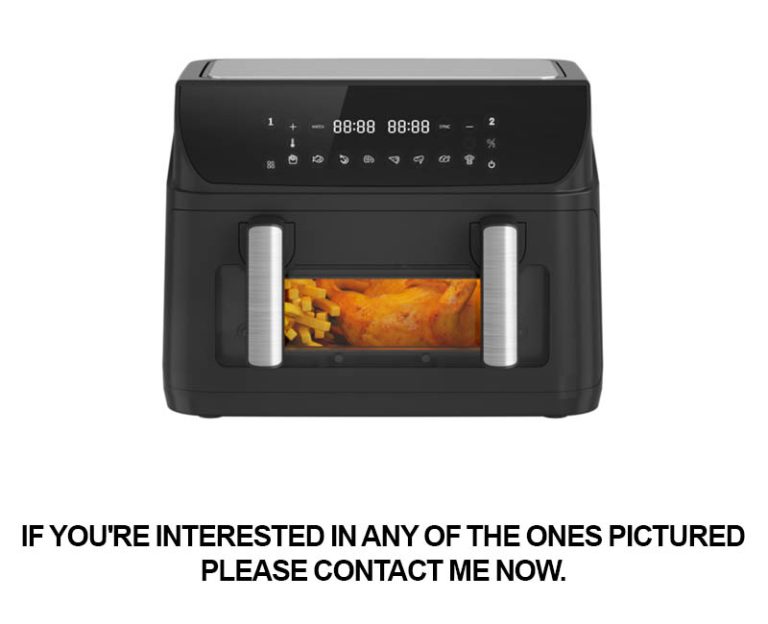

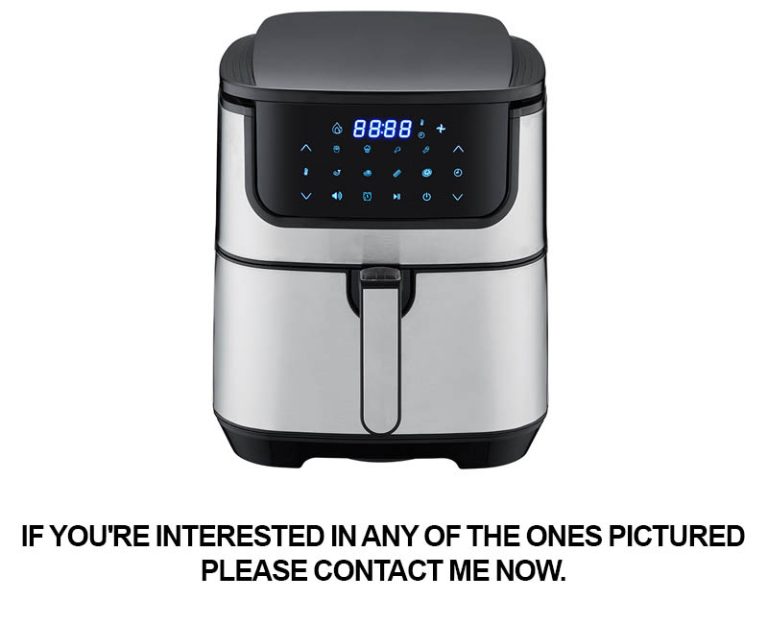

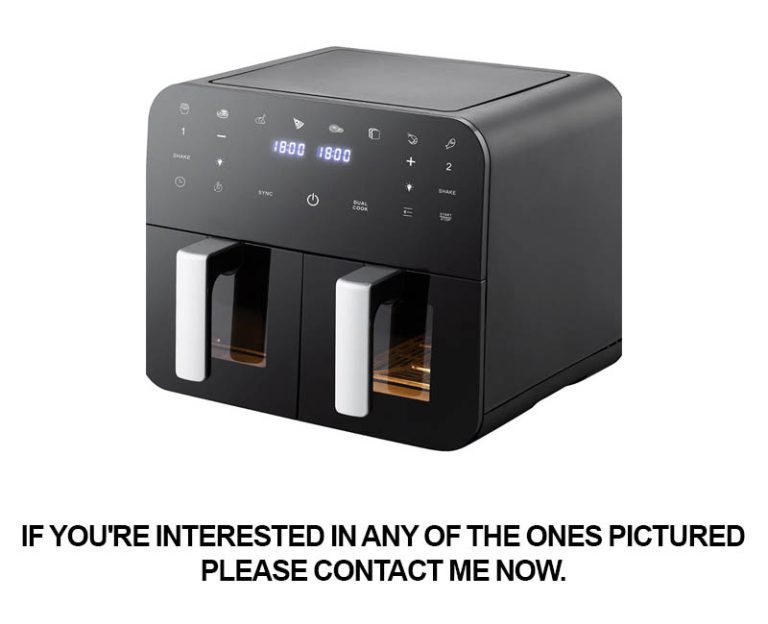

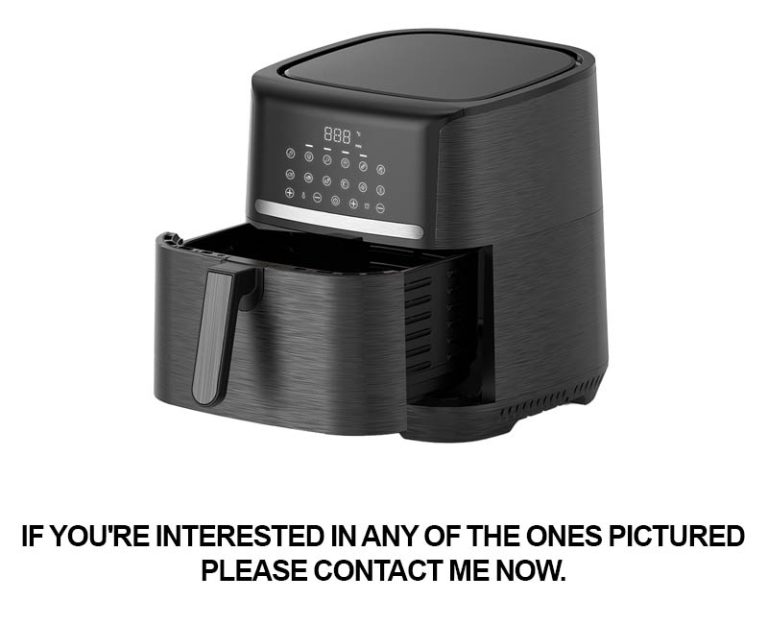

The NSF certified 1800W air fryer has revolutionized home cooking, offering a healthier alternative to traditional frying methods. With its innovative design and powerful 1800W motor, this appliance circulates hot air to create a crispy outer layer without excessive oil. The NSF certification ensures safety and performance, making it a trusted choice for those seeking to maintain a balanced diet. Its versatility, from crispy fries to baked goods, and its energy efficiency have made the 1800W air fryer a game-changer in the kitchen appliance market.

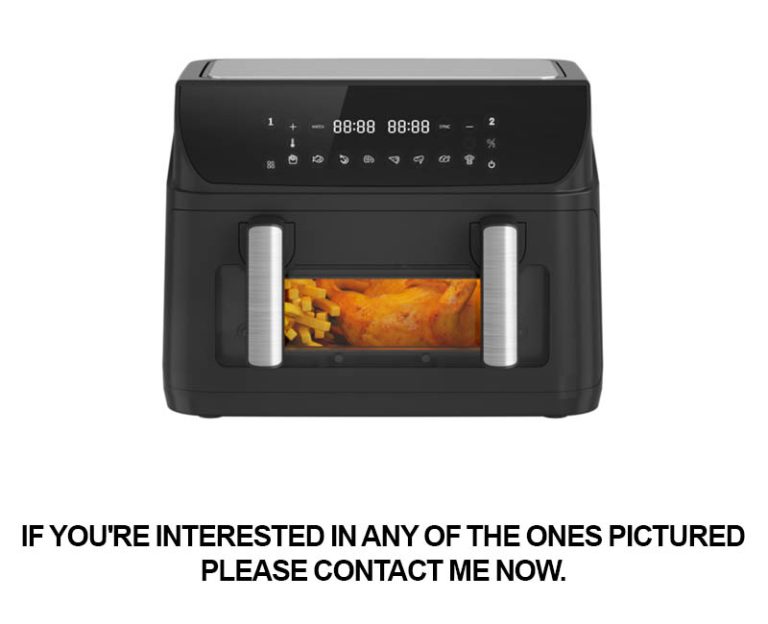

The ETL listed commercial unit has emerged as a pivotal advancement in kitchen appliances, emphasizing efficiency and safety. These units undergo rigorous testing to meet stringent safety standards, setting a gold standard for the industry. Their focus on energy efficiency and innovative features has revolutionized kitchen operations, enhancing productivity and sustainability. As the culinary landscape evolves, the ETL listed commercial unit stands as a symbol of reliability and quality, shaping the future of kitchen appliances.

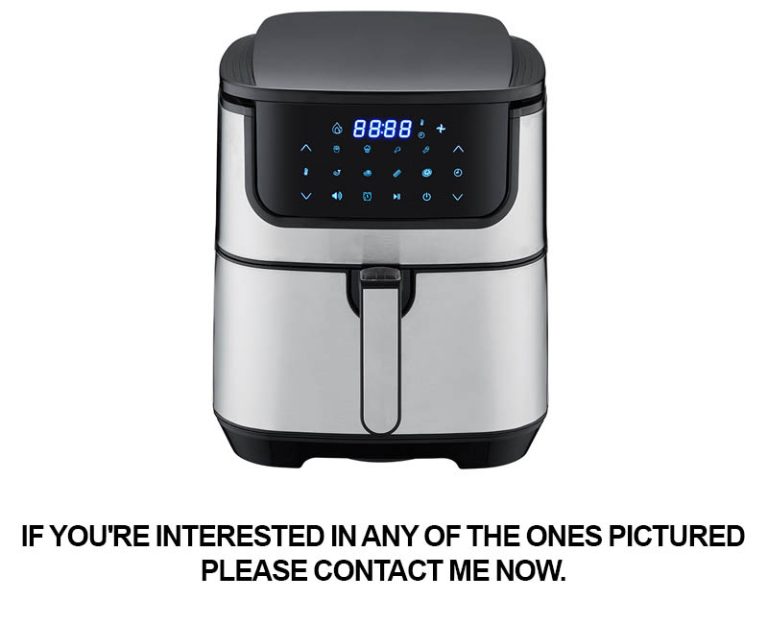

FOB Ningbo has emerged as a leading hub for air fryer suppliers, offering innovative and efficient cooking solutions. Known for their strategic location and robust manufacturing ecosystem, Ningbo’s suppliers provide high-quality air fryers that cater to the global market’s demand for healthier, convenient cooking. With a focus on cutting-edge design, functionality, and sustainability, FOB Ningbo air fryers are revolutionizing the way people cook, delivering delicious results with minimal oil and maximum versatility.

In the realm of kitchen appliances, the 2200W CE-EMC compliant appliance stands out as a game-changer, blending powerful performance with cutting-edge technology. This versatile device not only elevates cooking efficiency and safety but also embodies the future of culinary innovation. Its CE-EMC compliance ensures adherence to strict European and American standards, making it a reliable and safe choice for any kitchen. This high-powered kitchen appliance is designed to transform cooking experiences, offering precision, convenience, and energy efficiency, all while seamlessly integrating into the modern kitchen environment.

The Moscow Air Fryer Manufacturer has emerged as a leader in the air fryer market, offering innovative appliances that prioritize health and sustainability. Their air fryers, a staple in modern kitchens, have gained popularity for their ability to provide crispy, low-fat cooking alternatives to traditional frying methods. With a commitment to excellence and cutting-edge design, the Moscow air fryer manufacturer stands out for its commitment to efficiency and eco-friendly practices. Their versatile and user-friendly appliances, coupled with a focus on smart technology and sustainability, are reshaping the cooking landscape and solidifying their position as a global trendsetter in kitchen appliances.

In the culinary revolution, the commercial air fryer factory stands at the forefront, transforming cooking with its innovative appliances. These factories are not merely manufacturing air fryers; they are crafting the future of kitchen efficiency and health. The air fryer, once a niche product, has become a staple in commercial kitchens worldwide, offering a guilt-free fried taste without the excess oil. These factories push boundaries with smart technology integration, energy efficiency, and safety features, creating appliances that are both powerful and user-friendly. As consumer demand grows for healthier cooking options, commercial air fryer factories are responding with advanced models that cater to health-conscious lifestyles, all while expanding their global reach and shaping the future of cooking appliances.

The restaurant-grade air fryer factory stands as a testament to innovation and efficiency, churning out appliances that revolutionize home cooking. These air fryers, far from mere gadgets, are high-tech appliances that mimic the crispy texture of fried foods with a fraction of the oil, making them a health-conscious cook’s delight. Their advanced technology, from durable construction to smart controls, ensures consistent and perfect cooking results. The factory’s precision and commitment to quality produce air fryers that are not just kitchen tools but integral components of modern culinary experiences, offering convenience, versatility, and sustainability in every meal.

The heavy duty sandwich press factory has revolutionized kitchen appliances, offering a compact and powerful tool that perfectly presses sandwiches with ease. With key features such as durable construction, even heat distribution, and non-stick surfaces, these presses ensure every sandwich is cooked to perfection. The adjustable pressure and temperature controls guarantee consistent results, while the user-friendly design makes them a staple in modern kitchens. The factory’s commitment to quality and innovation has made the heavy duty sandwich press an indispensable appliance for achieving the perfect sandwich at home or in commercial settings.

The continuous operation sandwich grill plant represents a culinary revolution, harnessing advanced technology for efficient and consistent sandwich production. These innovative facilities operate 24⁄7, ensuring a seamless flow of high-quality sandwiches at a rapid pace. Their automated systems, from bread slicing to filling application, are precision-engineered to reduce waste and enhance food safety. With their modular design and smart automation, these plants are not only efficient but also adaptable, meeting the growing demand for fast, fresh, and customizable meals. As the fast-food industry evolves, the continuous operation sandwich grill plant is poised to be a pivotal player, setting new standards for cooking efficiency and technological innovation.

In the grill manufacturing sector, in-house mold making has emerged as a revolutionary technique, enabling manufacturers to create customized and advanced features for Grills. This process not only enhances the cooking experience but also allows for rapid prototyping and market responsiveness. By leveraging in-house mold making, manufacturers can produce Grills with unique features like ergonomic handles, innovative cooking surfaces, and integrated accessories, ultimately delivering a more personalized and efficient cooking solution. This evolution in manufacturing techniques has paved the way for a new era of Grills that cater to the diverse needs of cooking enthusiasts, offering unparalleled design flexibility and functionality.