Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

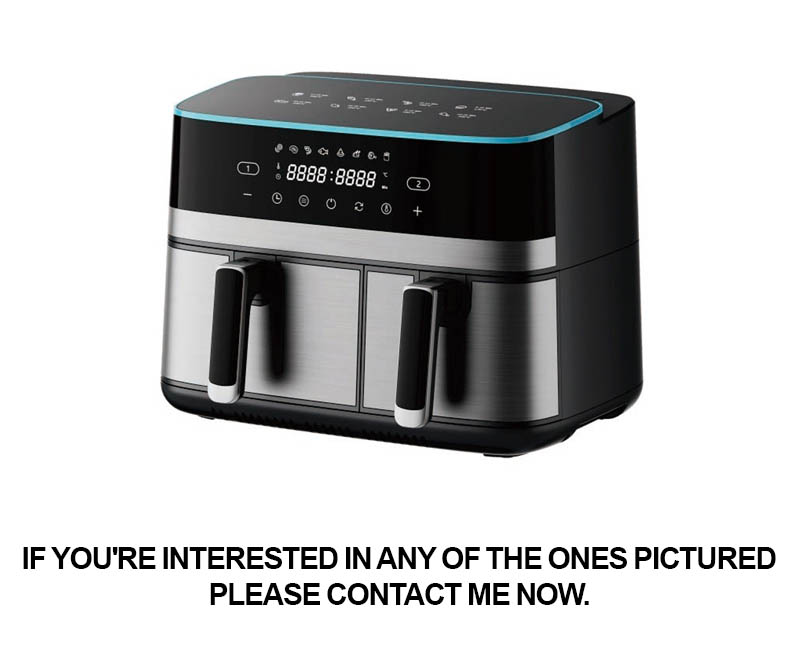

Navigating the world of air fryer manufacturers can be a daunting task, especially when you’re looking for a partner that not only meets your quality standards but also aligns with your business goals. It’s crucial to approach this process with a keen eye for detail and a strategic mindset. Trusting your instincts while conducting thorough due diligence is the key to making an informed decision. Let’s delve into the art of finalizing your choice in a way that ensures you’ve selected the perfect air fryer manufacturer for your needs.

When it comes to investing in an air fryer, the quality of the product can make or break your customer’s experience. That’s why partnering with a reliable air fryer factory is not just beneficial—it’s crucial. Here are several key reasons why choosing the right factory is so important.

Firstly, the reputation of the factory directly impacts the reputation of your brand. If the air fryers you sell are known for their durability and performance, it enhances your brand’s credibility. Conversely, if there are issues with the air fryers, it can tarnish your reputation and customer trust.

Secondly, the quality of the components used in the manufacturing process can significantly affect the longevity and performance of the air fryer. A reliable factory will use high-quality materials, ensuring that the final product is not only safe but also efficient and effective.

Thirdly, a trustworthy factory will have robust quality control measures in place. This means that each air fryer that leaves the factory has been thoroughly tested to meet safety standards and perform as expected. This level of assurance can prevent costly returns and customer dissatisfaction.

Moreover, the design and innovation of the air fryer are critical factors in its success. A factory that prides itself on creativity and innovation will be more likely to offer you a product that stands out in a crowded market. This can give your brand a competitive edge.

Fourthly, the manufacturing process itself is vital. A factory that employs advanced technology and efficient production methods can deliver a higher volume of air fryers at a faster rate, ensuring that you can meet your supply chain demands without delays.

Fifthly, consider the after-sales service. A reliable factory will offer excellent customer support, including technical assistance and parts replacement, which can save you time and money in the long run.

Sixthly, sustainability is a growing concern for consumers. A factory that prioritizes eco-friendly practices and materials can appeal to environmentally conscious customers, giving your brand an additional selling point.

Seventhly, the cost of manufacturing is a significant factor. A factory that offers competitive pricing without compromising on quality can help you maintain a healthy profit margin. It’s about finding that sweet spot between affordability and premium quality.

Eighthly, the ability to customize your air fryer is important. A factory that can tailor the product to your brand’s specifications or incorporate new features can make your product unique and more appealing to your target market.

Ninethly, consider the factory’s global reach. A factory that has a strong presence in various markets can help you expand your business internationally, offering you a competitive advantage in different regions.

Lastly, the factory’s willingness to adapt to market trends is crucial. The air fryer industry is constantly evolving, and a factory that stays ahead of the curve can provide you with cutting-edge products that keep your customers interested and coming back for more.

In summary, a reliable air fryer factory is not just a supplier; it’s a partner in your business success. From quality and innovation to customer service and sustainability, the right factory can make all the difference in how your customers perceive your brand and how your business performs in the market.

When it comes to selecting an air fryer manufacturer, there are several key qualities that can make or break your business. Here’s what to look for:

Innovation and Product DesignAn air fryer manufacturer that stands out is one that not only produces high-quality products but also leads the market in innovative design. Look for a company that invests in research and development, offering unique features and a sleek, modern look that appeals to today’s consumers.

Quality MaterialsThe durability and performance of an air fryer are heavily dependent on the materials used in its construction. Ensure the manufacturer uses premium, food-grade materials that are safe, long-lasting, and resistant to wear and tear.

Advanced TechnologyThe technology behind an air fryer is crucial. Seek out a manufacturer that employs state-of-the-art cooking technology, such as precise temperature control and advanced fan systems, which contribute to healthier and tastier cooking results.

Robust Quality ControlA reliable air fryer factory should have a stringent quality control process in place. This includes regular inspections, thorough testing of products, and a commitment to meeting industry standards. A company that prioritizes quality will likely deliver products that consistently meet customer expectations.

Customization OptionsDepending on your business needs, the ability to customize air fryers can be a significant advantage. A manufacturer that offers a range of customization options, such as different sizes, colors, or add-ons, can help you cater to diverse market demands.

Competitive PricingWhile quality is paramount, so is pricing. Look for a manufacturer that offers competitive pricing without compromising on the quality of the product. This balance ensures that you can offer your customers a great value without sacrificing profits.

Strong Supply Chain ManagementA robust supply chain is essential for ensuring that you receive your orders on time and in full. A reliable air fryer factory should have a well-established supply chain that minimizes delays and guarantees a steady flow of inventory.

Excellent Customer ServiceThe level of customer service you receive from a manufacturer can reflect their dedication to their customers. Ensure that the company offers responsive customer service, including clear communication, technical support, and after-sales care.

Compliance with International StandardsIf you plan to export your air fryers, it’s important to work with a manufacturer that complies with international safety and quality standards. This includes certifications like CE, FDA, and other relevant regulatory approvals.

Sustainability PracticesIn today’s market, sustainability is a growing concern. Look for a manufacturer that is environmentally conscious, using eco-friendly materials and practices in their production process. This not only aligns with consumer values but can also be a competitive edge.

In-house Production CapabilitiesA manufacturer with in-house production capabilities often has better control over the quality and speed of production. This means they can respond quickly to changes in demand and maintain a high level of product consistency.

Flexibility in Production VolumeYour business may fluctuate in terms of orders, so it’s important to work with a manufacturer that can scale their production to match your needs. This flexibility ensures that you can meet peak demand without experiencing stockouts.

Marketing and Branding SupportA manufacturer that provides marketing and branding support can help you build a strong brand presence. Look for companies that offer co-branding opportunities, packaging design assistance, and other marketing resources.

Feedback and Continuous ImprovementA good air fryer manufacturer values feedback from their customers and uses it to continuously improve their products and services. They should be open to suggestions and willing to make changes based on customer needs.

Longevity and Track RecordFinally, consider the longevity of the manufacturer and their track record in the industry. A company that has been around for a while and has a history of satisfied customers is likely to be more reliable and stable in the long term.

Navigating the online landscape, it’s crucial to delve into the depths of an air fryer manufacturer’s reputation. From customer testimonials to expert opinions, here’s how to sift through the information to get a clear picture:

Customer Reviews: Dive into the world of customer reviews on various platforms. Look for patterns in feedback regarding the quality, durability, and performance of the air fryers. Pay attention to both positive and negative comments, as they offer a balanced view of the product and the manufacturer’s responsiveness.

Social Media Engagement: Social media can be a treasure trove of information. Follow the manufacturer on platforms like Facebook, Instagram, and Twitter. Observe how they interact with customers, handle complaints, and share updates about their products. A proactive and customer-centric approach is a good sign.

Expert Opinions: Seek out reviews and analyses from kitchen experts, food bloggers, and tech enthusiasts. These individuals often provide detailed insights into the technical aspects of air fryers, their performance, and the overall value they offer. Their professional assessments can be incredibly informative.

Industry Awards and Recognitions: Check if the air fryer manufacturer has received any awards or been recognized by industry associations. Accolades like “Best Air Fryer of the Year” or “Innovative Design Award” can indicate a high standard of quality and innovation.

Testimonials from Retailers: Retailers who stock the air fryers can offer valuable insights. Look for testimonials or interviews with store managers or buyers who have firsthand experience with the manufacturer’s products. They can provide information on product reliability and customer satisfaction.

Product Warranties and Support: The warranty offered by the manufacturer is a reflection of their confidence in the product’s quality. A comprehensive warranty and responsive customer support can be a strong indicator of a reliable manufacturer.

Online Forums and Communities: Join online forums and communities dedicated to kitchen appliances and cooking. Members often share their experiences with different brands and models. This can be a direct line to real-world experiences with the air fryer manufacturer in question.

Comparative Analysis: Compare the manufacturer’s air fryers with competitors. Look at factors like price, features, customer reviews, and overall brand reputation. This comparative analysis can help you identify the standout qualities of the manufacturer in question.

Feedback on Post-Sales Service: Good manufacturers not only provide quality products but also excellent post-sales service. Look for reviews that mention the ease of returning products, the speed of replacements, and the helpfulness of customer service.

Longevity of the Brand: A manufacturer that has been in the industry for a while is likely to have a solid reputation. Longevity can be a testament to their ability to adapt to market changes and maintain customer satisfaction over time.

By thoroughly researching these aspects, you can build a comprehensive understanding of an air fryer manufacturer’s reputation and make an informed decision about whether they are the right choice for your needs.

Navigating the complexities of quality control and standards in an air fryer manufacturer is akin to uncovering the heart of a product’s reliability and longevity. Here’s a deep dive into what to look for:

Consistency in ProductionThe consistency of the manufacturing process is paramount. A reputable air fryer factory maintains strict protocols to ensure that every unit produced meets the same high standards. This means that whether you’re inspecting the first or the hundredth air fryer off the line, the quality remains unwavering.

Robust Quality Assurance ProtocolsA top-tier air fryer manufacturer employs rigorous quality assurance protocols. This includes multiple layers of checks, from raw material inspections to the final product testing. These protocols are designed to catch any discrepancies or defects early in the production cycle.

Certifications and ComplianceLook for certifications such as ISO 9001, which guarantees a quality management system that meets international standards. Compliance with these standards means the factory has been evaluated and found to meet specific criteria for quality, environmental management, and safety.

Material SelectionThe choice of materials is a clear indicator of a manufacturer’s commitment to quality. High-quality air fryers are made with durable materials that can withstand heat, pressure, and wear. Check if the manufacturer specifies the types of metals, plastics, and coatings used in their air fryers.

In-House TestingA reliable air fryer factory conducts extensive in-house testing. This includes durability tests, temperature accuracy checks, and safety assessments. These tests are not just limited to individual components but also to the entire product to ensure it performs as expected under various conditions.

Industry Standards and Best PracticesThe factory should adhere to industry standards and best practices. This means they are not just following regulations but also staying abreast of new technologies and methodologies that can enhance the quality of their products.

Feedback LoopAn effective quality control system includes a feedback loop. The factory should collect and analyze customer feedback to identify potential issues and areas for improvement. This shows a commitment to continuous improvement and customer satisfaction.

Training and ExpertiseThe workforce in the factory should be well-trained and experienced. Skilled workers are less likely to make mistakes and more likely to understand the importance of quality in every step of the manufacturing process.

Environmental and Safety StandardsBeyond the product itself, a quality-conscious manufacturer will also ensure that their operations meet environmental and safety standards. This includes using eco-friendly materials, minimizing waste, and maintaining a safe working environment for their employees.

Supply Chain ManagementThe integrity of the supply chain is crucial. A reputable air fryer factory will have strong relationships with suppliers who provide high-quality components. This ensures that the raw materials are of the highest standard before they even reach the production line.

Warranty and After-Sales ServiceThe warranty and after-sales service policies are a reflection of a manufacturer’s confidence in their product’s quality. A longer warranty period and responsive customer service can be signs of a company that stands behind its products.

TransparencyLastly, a good air fryer factory is transparent about their processes and standards. They are not afraid to share details about their quality control measures and are open to discussing any concerns you may have.

By examining these aspects of quality control and standards, you can gain a comprehensive understanding of whether an air fryer manufacturer is committed to producing a high-quality product that you can trust.

Navigating through the myriad of air fryer manufacturers, it’s crucial to evaluate their production capacity and efficiency. This assessment can make a significant difference in the quality and reliability of the products you choose to distribute or sell. Here’s a deeper look into what you should consider:

Understanding Scale of OperationThe size of the factory and the scale of its operations can give you insights into its capacity. Larger factories often mean more space for advanced machinery and a higher volume of production. However, it’s not just about size; it’s about how well the factory utilizes its resources.

Automated vs. Manual ProductionThe degree of automation in the production process can affect both the efficiency and the quality of the air fryers. Factories that heavily rely on automated systems can produce more units in less time with fewer errors. Conversely, manual labor-intensive factories may offer a more hands-on approach but might not match the speed of automated counterparts.

Current Production VolumeDetermine the current production volume to gauge how well the factory manages its resources. If they’re consistently meeting or exceeding their production goals, it’s a sign of good efficiency. On the other hand, if they’re struggling to keep up with orders, it could indicate potential bottlenecks or inefficiencies.

Lead Times and Turnaround TimesPay attention to the lead times—the time from order placement to delivery—and turnaround times—the time from order placement to when the product is ready for shipping. Shorter lead and turnaround times suggest a well-optimized production process and a factory that can handle high demand without delays.

Capacity for Scaling UpA reliable air fryer manufacturer should have the capability to scale up production as demand increases. This means they should have the infrastructure, workforce, and technology in place to handle an increase in orders without compromising quality.

Inventory ManagementEfficient inventory management is key to maintaining a steady flow of production. A factory that struggles with inventory control might experience stockouts or overstock situations, both of which can be costly and disruptive.

Resource UtilizationEvaluate how well the factory uses its resources, including raw materials, energy, and labor. Efficient use of resources not only reduces costs but also minimizes the environmental impact, which is an increasingly important factor for consumers and businesses alike.

Quality Assurance MeasuresA manufacturer’s production capacity and efficiency are also reflected in their quality assurance processes. Look for a factory that has a robust quality control system in place, ensuring that each air fryer meets or exceeds industry standards.

Training and Development ProgramsA factory that invests in training and development programs for its workforce is likely to have a more efficient operation. Employees who are well-trained are more productive and less likely to make mistakes that could slow down production.

Feedback from Customers and DistributorsSometimes, the best way to assess a factory’s production capacity and efficiency is to hear it directly from those who work with them. Seek feedback from current customers and distributors to get a sense of the factory’s reliability and the consistency of their products.

Adaptability to New TechnologiesThe ability to adapt to new technologies and innovations is a hallmark of an efficient manufacturer. A factory that continuously updates its technology is likely to maintain high levels of production and quality.

Long-Term Vision and PlanningA manufacturer with a clear long-term vision and strategic planning is better positioned to manage production capacity and efficiency. They are more likely to anticipate market trends and adjust their production accordingly.

By thoroughly examining these aspects of an air fryer manufacturer’s production, you can gain a comprehensive understanding of their capabilities and how well they can meet your needs. It’s an investment of time that can pay off in the form of high-quality products and reliable supply.

Navigating the world of certifications and compliance can be a complex task, especially when dealing with a manufacturer of air fryers. It’s crucial to understand the significance of these factors to ensure that the products you’re considering meet both industry standards and your own expectations. Here’s a closer look at what to consider:

Understanding the Importance of CertificationsCertifications serve as a seal of approval, indicating that a product or manufacturing process has been evaluated and meets specific standards. In the case of air fryer manufacturers, certifications can range from safety to environmental impact. It’s important to research what certifications are relevant to your needs, such as CE for Europe, UL for the United States, or ROHS for restricted substances.

Identifying Relevant CertificationsNot all certifications are created equal. For instance, a CE mark is a crucial indicator for European markets, but it doesn’t guarantee the same level of safety or quality as other certifications. Look for certifications that are recognized and respected in the regions where you plan to sell your air fryers. For example, if you’re targeting the U.S. market, certifications like UL and ETL are essential.

Verifying Certification AuthenticityOnce you’ve identified the relevant certifications, it’s vital to verify their authenticity. This can be done by checking the manufacturer’s website for the certification logos, as well as looking for the certification bodies’ own websites to confirm the validity of the certificates. Be wary of manufacturers who may display forged or expired certifications.

Assessing Compliance with International StandardsInternational standards, such as ISO (International Organization for Standardization), provide a framework for quality management and environmental sustainability. A manufacturer that complies with ISO standards is likely to have robust quality control processes. Check if the manufacturer adheres to these standards and inquire about their specific certifications under the ISO framework.

Environmental and Social ResponsibilityIn today’s market, consumers and businesses alike are increasingly concerned about the environmental and social impact of their purchases. Look for manufacturers that have certifications indicating their commitment to sustainability, such as the Energy Star label for energy efficiency or the Fair Trade certification for ethical sourcing. These certifications can also extend to labor practices and working conditions within the factory.

Reviewing the Scope of ComplianceA manufacturer’s compliance with standards is not just about having certifications; it’s about the scope of compliance. Some certifications are broad and cover multiple aspects of the business, while others are more specific. Ensure that the compliance extends to the entire product lifecycle, from design and production to distribution and recycling.

Understanding the Certification ProcessUnderstanding how the certification process works can give you insight into the manufacturer’s commitment to quality and compliance. Ask about the frequency of audits and the criteria used for certification. A manufacturer that undergoes regular audits and has a transparent process is more likely to maintain high standards.

Evaluating the Impact of Certifications on Product PricingWhile certifications are important, they can also affect the cost of products. High-quality certifications often come with a premium. Consider whether the added cost is justified by the improved quality and reliability of the air fryers.

Seeking Third-Party EndorsementsThird-party endorsements can provide additional credibility. Look for independent organizations that have tested and recommended the manufacturer’s air fryers. These endorsements can come in the form of awards, reviews, or rankings within the industry.

Checking for Recency of CertificationsCertifications are not eternal; they expire and need to be renewed. A manufacturer that regularly updates its certifications demonstrates a continuous commitment to maintaining high standards. Make sure that the certifications are current and not expired.

Understanding the Certification’s Recognition in Target MarketsDifferent markets may recognize different certifications. For example, the FDA approval in the U.S. may be more important than a CE mark in certain other countries. Tailor your research to the specific requirements and expectations of your target markets.

By thoroughly assessing certifications and compliance, you can gain confidence in the quality and reliability of the air fryers you’re considering. It’s an investment in both the product and the trust of your customers.

Understanding the importance of a reliable air fryer manufacturer is crucial in today’s competitive market. With countless options out there, finding a partner that not only produces high-quality products but also aligns with your business values can be a daunting task. Let’s delve into the intricacies of identifying such a manufacturer.

Quality Control and StandardsEnsuring that an air fryer manufacturer maintains stringent quality control measures is essential. This involves a rigorous inspection process, adherence to international safety standards, and the use of premium materials. A quality-driven manufacturer will have a track record of producing durable, reliable, and safe appliances.

Innovation and DesignThe manufacturer should be known for its innovative approach to design. This means not just creating a functional product but also one that stands out in terms of aesthetics and user experience. Look for a company that invests in research and development to push the boundaries of what’s possible in air fryer technology.

Market Trends and Consumer InsightsA forward-thinking manufacturer will have a keen eye on current market trends and consumer preferences. They should be able to adapt quickly to changing demands and provide solutions that cater to the evolving needs of consumers. This includes understanding the latest health and wellness trends that influence kitchen appliance purchases.

Customer Service and SupportExceptional customer service is a hallmark of a reliable manufacturer. This extends beyond just sales and includes post-purchase support, technical assistance, and a willingness to address any concerns or issues promptly. A company that values its customers will invest in training its staff to provide top-notch service.

Sustainability and Environmental ResponsibilityIn today’s world, sustainability is a significant factor in business decisions. A manufacturer that prioritizes environmentally friendly practices, such as using recyclable materials or minimizing energy consumption during production, is not only good for the planet but also likely to resonate with eco-conscious consumers.

Global Reach and DistributionA manufacturer with a strong global presence indicates its products are well-received in various markets. This can be a good sign that the company has a robust supply chain and the ability to handle international shipping and logistics. It also suggests that the manufacturer has the capacity to scale up production as needed.

Customization and FlexibilityNot every business has the same requirements. A manufacturer that offers customization options can be a valuable partner. Whether it’s branding, specific features, or bulk orders, the ability to tailor products to your business needs is a significant advantage.

Financial Stability and Business EthicsBefore committing to a manufacturer, it’s important to assess their financial stability. A company with a solid financial foundation is more likely to be reliable and capable of fulfilling long-term partnerships. Additionally, consider their business ethics, including how they treat their employees and how they manage their operations.

Product Range and VarietyA comprehensive product range demonstrates that the manufacturer is committed to meeting a wide array of customer needs. Whether you’re looking for countertop models, commercial units, or portable options, a diverse portfolio can cater to different market segments.

Feedback from Existing CustomersHearing directly from other businesses that have worked with the manufacturer can provide invaluable insights. Positive testimonials, case studies, and references can give you confidence in the manufacturer’s ability to deliver on its promises.

Remember, finding a reliable air fryer manufacturer is about aligning with a partner who shares your vision and values. It’s not just about the product; it’s about the entire experience, from initial contact to long-term collaboration. Take the time to thoroughly research and evaluate potential manufacturers to ensure you’re making the best choice for your business.

Understanding the layout of the factory is crucial. You want to see how the space is utilized and if it’s optimized for production. Walk through the facility, observing the flow of materials and products. Is there a logical sequence from raw materials to finished goods?

Inspecting the cleanliness of the factory is non-negotiable. A clean environment is indicative of good hygiene practices, which are essential for maintaining product quality. Look for dust-free areas, spotless machinery, and employees who follow strict sanitation protocols.

Machinery and TechnologyThe technology used in the manufacturing process can significantly impact the quality and efficiency of the air fryers. Take a close look at the machinery. Are the machines state-of-the-art, or are they outdated? Modern equipment often translates to better quality control and higher production speeds.

Employee Training and Skill LevelThe skill level of the workforce is a key indicator of the factory’s quality. Observe how employees interact with the machinery and whether they seem well-trained. Ask about the training programs in place for new hires and the ongoing development of current staff.

Quality Control ProcessesQuality control is paramount in the production of air fryers. Look for signs of a robust quality control system. Are there inspection stations at various stages of production? Do employees use checklists or digital systems to ensure that each product meets specifications?

Safety MeasuresFactory safety is a critical aspect that should not be overlooked. Note the presence of safety equipment like fire extinguishers, first aid kits, and emergency exits. Observe if there are clear safety procedures in place, and whether employees are adhering to them.

Material HandlingEfficient material handling is essential for smooth production. Watch how raw materials are stored and transported within the factory. Are there organized systems for inventory control? Are there measures in place to prevent damage or contamination during handling?

Communication and CollaborationThe ability to communicate and collaborate effectively is vital for any successful factory. Observe how employees interact with each other and with management. Are there open lines of communication? Do team members work together seamlessly?

Flexibility and ScalabilityA factory that can adapt to changing demands is more likely to produce high-quality air fryers consistently. Ask about the factory’s ability to scale up production quickly if needed and how they handle custom orders or changes in product specifications.

Environmental ConsiderationsIn today’s market, environmental responsibility is increasingly important. Inquire about the factory’s efforts to minimize waste, reduce energy consumption, and use sustainable materials. Look for any certifications that indicate a commitment to environmental stewardship.

Customer FeedbackIf possible, gather information about customer feedback on the air fryers produced by the factory. Are there common complaints or praises? This can give you insight into the real-world performance and quality of the products.

Long-Term PartnershipsEstablishing a long-term partnership with a factory is beneficial. Look for signs that the factory values long-term relationships with its customers. Are there incentives for repeat business? Do they offer support and service after the sale?

Final ImpressionsAfter your visit, take a moment to reflect on your overall impression. Did the factory leave you with a sense of confidence in their ability to produce high-quality air fryers? Trust your instincts and consider all the factors you’ve observed when making your decision.

Navigating the fine print is crucial when it comes to locking in deals with an air fryer factory. Here’s how to ensure you’re not just getting a product, but a partnership that aligns with your business goals.

Understanding Contractual Details

It’s not just about the price; it’s about the entire package. When reviewing terms, delve into the specifics of the contract. Look at the delivery schedules, minimum order quantities, and any penalties for late deliveries. These details can impact your inventory management and customer satisfaction.

Checking Payment Terms

Payment terms can vary widely, from upfront payments to installment plans. Be clear about when and how you’ll be invoiced. Consider the impact of payment terms on your cash flow and whether the factory’s terms align with your business’s financial strategy.

Evaluating Warranty and Support

Warranties are a key indicator of a manufacturer’s confidence in their product. Make sure the warranty covers not just defects but also typical wear and tear. Additionally, inquire about the level of customer support provided. A responsive support team can be invaluable when issues arise.

Negotiating Production Times

Lead times can be just as important as pricing. Discuss the factory’s production capacity and how it will affect your order deadlines. If they’re unable to meet your desired timeframe, understand the reasons and whether they offer expedited services at an additional cost.

Reviewing Intellectual Property Rights

Intellectual property is crucial, especially if you’re looking for custom solutions. Ensure that the contract clearly outlines ownership of designs, patents, and any other intellectual property that arises from the partnership. This protects your investment and future market position.

Considering Logistics and Shipping

Logistics can make or break a deal. Discuss shipping costs, insurance, and the responsibility for handling damages during transit. Be transparent about customs procedures and any potential tariffs that may affect the final cost to your customer.

Understanding Quality Assurance Protocols

Before signing on the dotted line, ensure that the factory has robust quality assurance protocols. This includes the processes they use to test products, how they handle defective items, and their approach to continuous improvement. These protocols can impact the reputation of your brand.

Discussing Product Customization

If customization is part of your agreement, it’s vital to have clear terms about what’s possible, how much it will cost, and how long it will take. Be prepared to negotiate the specifics of any custom design to ensure it meets your product specifications and timelines.

Setting Clear Communication Channels

Effective communication is key to a successful partnership. Establish how and how often you will communicate with the factory. This includes regular updates on production status, any issues that arise, and how disputes will be resolved.

Reviewing Contract Renewal and Exit Clauses

No matter how promising a partnership seems, it’s important to have clear terms for contract renewal and how to handle the end of the agreement. This includes understanding any exit fees, how the transition will be managed, and how any existing orders will be handled.

Assessing Legal and Compliance Issues

Finally, make sure that the contract complies with all relevant laws and regulations. This includes employment laws, environmental regulations, and international trade laws. Non-compliance can lead to legal issues and damage your brand’s reputation.

By thoroughly examining and negotiating these terms, you can build a strong foundation for a mutually beneficial relationship with your air fryer factory. It’s not just about getting the best deal; it’s about setting up a partnership that can grow with your business.

Navigating the fine line between intuition and thorough research can be a challenging aspect of finalizing your choice for a business partner. When it comes to selecting an air fryer manufacturer, it’s crucial to not only rely on logical analysis but also to trust your instincts and ensure you’ve conducted due diligence. Here’s how to balance these two approaches:

Remember that your gut feeling often stems from a combination of past experiences, market knowledge, and instincts. It’s the whisper in the back of your mind that tells you someone or something is right for you. In the world of manufacturing, this might mean a factory that just feels right, with an efficient layout, a motivated workforce, and a vibe that resonates with your values.

Understanding the technical specifications of the air fryers you’re interested in is essential. Look for manufacturers that offer a range of models with different capacities, power outputs, and features. A diverse product line can indicate a company that invests in innovation and caters to various market needs.

When it comes to due diligence, it’s about digging deeper into the facts and figures. Investigate the company’s financial health to ensure they can weather any potential market downturns. Look into their track record with past clients, especially those who require similar products and services. This can give you a sense of their reliability and customer satisfaction.

The quality of the components used in the air fryers can speak volumes about the manufacturer’s commitment to excellence. Inspect the materials and ask about the sourcing process. A reputable factory will be transparent about where their components come from and how they ensure their suppliers meet high-quality standards.

One of the most telling signs of a reliable manufacturer is their willingness to engage in open communication. Whether it’s discussing production timelines, shipping logistics, or after-sales service, a company that keeps the lines of communication open is more likely to be a good partner. Pay attention to how promptly and effectively they address your questions and concerns.

It’s not just about what a manufacturer can do for you; it’s also about how they do it. Look for evidence of a structured process, from design and prototyping to production and quality control. A well-oiled machine with a clear process in place is less likely to encounter setbacks or delays.

When you’re considering an air fryer manufacturer, consider the scalability of their operations. Can they handle increased production demands if your business grows? A manufacturer with a strong infrastructure and the ability to scale up can be a crucial asset in the long term.

Don’t underestimate the power of referrals and testimonials. Reach out to other businesses in your industry and ask about their experiences with the manufacturers they’ve worked with. Personal recommendations can provide invaluable insights into the day-to-day operations and the level of service you can expect.

In the world of business, relationships are key. Look for a manufacturer that values building long-term relationships with their clients. This means they’re invested in your success and are willing to go the extra mile to ensure you’re satisfied with their products and services.

Trust your instincts when it comes to the overall vibe of the company. If the team seems passionate, knowledgeable, and dedicated, it’s a good sign that they’re committed to producing high-quality air fryers. Conversely, if something feels off, it might be worth looking elsewhere.

Lastly, always have a contingency plan. Even after thorough research and a strong gut feeling, unexpected challenges can arise. A manufacturer who is adaptable and has a history of overcoming obstacles is a better bet in the long run.

In summary, finalizing your choice of an air fryer manufacturer requires a blend of intuitive decision-making and meticulous due diligence. Trust your gut to guide you towards a company that aligns with your values and vision, but back it up with thorough research to ensure they can deliver on their promises. With the right balance, you’ll find a partner that not only meets your immediate needs but also grows with your business.