Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where convenience meets health-conscious cooking, ceramic coated non-stick plates have emerged as a beacon of innovation in the kitchenware industry. These plates, with their sleek design and eco-friendly coatings, have captured the attention of consumers seeking a balance between performance and sustainability. As we delve into the intricacies of these products, it becomes clear that their rise is not just a fleeting trend but a testament to the evolving demands of the modern culinary landscape.

The market for ceramic coated non-stick cookware has seen a remarkable surge in popularity in recent years. Once a niche product, it has now become a staple in many kitchens across the globe. This shift can be attributed to several key factors that have propelled ceramic coated non-stick cookware to the forefront of the culinary world.

Consumer awareness of health and wellness has been a significant driver in this trend. Many people are looking for alternatives to traditional non-stick coatings, which can contain potentially harmful chemicals like PFOA and PTFE. Ceramic coatings, on the other hand, are free from these chemicals and are often perceived as a safer option for cooking.

Additionally, the versatility of ceramic coated cookware has played a crucial role in its rise. These pans and pots are not only excellent for non-stick properties but also for their durability and heat distribution. They can handle high temperatures without warping or peeling, making them suitable for a wide range of cooking techniques from sautéing to baking.

The aesthetic appeal of ceramic coated non-stick cookware cannot be overlooked. The sleek, modern designs and vibrant colors have made them a favorite among interior designers and homeowners seeking to add a touch of elegance to their kitchenware. The glossy finish and clean lines have become a statement piece in many kitchens, enhancing the overall aesthetic of the space.

The environmental movement has also contributed to the popularity of ceramic coated cookware. With a lifespan that often exceeds that of traditional non-stick pans, these products are seen as a more sustainable choice. They can be used for years without the need for frequent replacement, reducing waste and the carbon footprint associated with manufacturing new cookware.

Innovation in manufacturing processes has made ceramic coated non-stick cookware more accessible and affordable. Advances in technology have allowed for the creation of high-quality ceramic coatings that are durable and long-lasting. This has helped to drive down costs, making ceramic coated cookware a more attainable option for a broader market.

The global kitchenware industry has taken notice of this shift, with many manufacturers jumping on board to produce ceramic coated cookware. This has led to a competitive landscape, with brands offering a variety of designs, sizes, and price points to cater to different consumer needs.

In the culinary world, chefs have also embraced ceramic coated non-stick cookware. The ability to use high heat without damaging the coating has made these products a favorite among professional cooks. The non-stick surface allows for the creation of delicate dishes with ease, while the even heat distribution ensures that food is cooked to perfection.

The rise of ceramic coated non-stick cookware is also a testament to the power of marketing and social media. Influencers and home cooks have been instrumental in promoting these products through reviews, tutorials, and demonstrations. Their endorsement has helped to build trust and credibility, encouraging more consumers to try ceramic coated cookware.

The market for ceramic coated non-stick cookware is not just growing; it’s evolving. As consumers continue to seek out healthier, more sustainable, and aesthetically pleasing kitchenware, ceramic coatings are poised to remain a key player in the industry. The future looks bright for this innovative and versatile cookware option, with endless possibilities for new designs and applications.

Ceramic coated non-stick cookware has emerged as a game-changer in the kitchen appliance industry, offering a host of benefits that have revolutionized the way we cook and maintain our cooking utensils. Here’s why this innovation is shaking things up:

The first notable advantage of ceramic coatings is their exceptional non-stick properties. Unlike traditional non-stick coatings that can degrade over time, ceramic coatings are highly durable and maintain their non-stick qualities even after countless uses. This means that you can cook a variety of dishes without worrying about food sticking to the surface, reducing the need for excessive oil or butter.

Not only does ceramic coating enhance the cooking experience, but it also contributes to healthier eating habits. With less oil required, dishes become lower in calories and fat, making them a healthier option for those conscious of their diet. This aspect alone has garnered a significant following among health-conscious consumers who are always on the lookout for ways to improve their culinary habits.

Durability is another key factor that sets ceramic coated cookware apart. These coatings are resistant to scratches and abrasions, which means that your pans and skillets can withstand the rigors of daily use without showing signs of wear. This longevity not only saves money in the long run but also ensures that your cookware remains effective and efficient for years to come.

The eco-friendliness of ceramic coated cookware cannot be overstated. Unlike non-stick pans with PTFE (Teflon) coatings, which can release harmful fumes when overheated, ceramic coatings are free of harmful chemicals. This makes them a safer choice for both the consumer and the environment, as they do not degrade into toxic substances that could contaminate food or the atmosphere.

The aesthetic appeal of ceramic coated cookware is also a significant draw. The smooth, sleek surface of these cookware pieces comes in a variety of colors and designs, allowing them to complement any kitchen decor. Whether you have a modern, minimalist kitchen or a traditional, rustic one, there’s a ceramic coated piece that can fit right in.

Ease of cleaning is a hallmark of ceramic coated cookware. The non-stick surface makes food release effortlessly, which means less time scrubbing and more time enjoying your meal. This is particularly beneficial for those who are short on time or prefer not to spend hours cleaning up after cooking.

One of the most remarkable aspects of ceramic coatings is their ability to retain heat evenly. This ensures that your food cooks evenly and consistently, leading to better-tasting dishes. The even heat distribution is often a challenge with traditional cookware, but ceramic coatings have solved this issue, making them a favorite among professional chefs and home cooks alike.

The versatility of ceramic coated cookware is another game-changing feature. These pieces can be used on various types of cooktops, including induction, gas, electric, and ceramic, making them a universal addition to any kitchen. This means that whether you’re using a classic stove or the latest in kitchen technology, you can still rely on your ceramic coated cookware.

The market has responded positively to these advancements, with ceramic coated non-stick cookware becoming increasingly popular. Retailers and manufacturers are seeing a surge in demand, and it’s not hard to see why. The combination of health benefits, durability, eco-friendliness, aesthetic appeal, and ease of use has created a product that checks all the boxes for consumers.

In the realm of innovation, the introduction of ceramic coatings has paved the way for new designs and functionalities. From induction-ready cookware to cookware with built-in temperature controls, the possibilities are endless. This innovation has spurred a wave of creativity in the kitchen appliance industry, leading to a constant stream of new products that cater to the evolving needs and preferences of consumers.

In conclusion, ceramic coated non-stick cookware has indeed become a game-changer. Its numerous benefits have redefined what we expect from our cookware, offering a healthier, more durable, and visually appealing alternative to traditional options. It’s no wonder that this innovation has taken the kitchen appliance world by storm.

In the heart of the manufacturing landscape, there lies a factory dedicated to transforming the culinary world with its cutting-edge ceramic coated non-stick plates. This factory is not just a place of production; it’s a hub of innovation and quality. Let’s take a closer look at what makes this factory a beacon in the cookware industry.

The factory’s layout is meticulously designed to optimize efficiency without compromising on quality control. As you step inside, you’re greeted by rows upon rows of highly automated machinery, each specialized in its role in the production process. The seamless blend of advanced technology and skilled craftsmanship is evident from the moment you arrive.

Workers, donned in white coats and gloves, move with precision, ensuring that every piece of cookware that leaves the factory is up to the highest standards. The use of robots and AI in the initial stages of manufacturing means that the plates are precision-cut and shaped with unparalleled accuracy, setting the stage for the ceramic coating process.

The ceramic coating itself is a marvel of modern science. This factory employs a proprietary method that involves a multi-layer application process, each layer being baked on at specific temperatures to ensure optimal bonding and durability. The result is a non-stick surface that is not only incredibly smooth but also resistant to scratches, stains, and wear.

As the plates move through the factory, they are inspected at various checkpoints. Each plate is subjected to rigorous tests, including non-stick performance checks, thermal shock resistance, and durability trials. These tests are crucial in guaranteeing that the final product will not only look great but also stand up to the demands of everyday cooking.

The factory’s commitment to sustainability is also noteworthy. Energy-efficient lighting and machinery reduce the carbon footprint, while waste is meticulously sorted and recycled where possible. This eco-conscious approach is reflected in the product, as the ceramic coating is free from harmful chemicals like PFOA and PTFE, making it a healthier choice for consumers.

The factory’s focus on continuous improvement is evident in its investment in research and development. Engineers and designers work tirelessly to innovate, exploring new materials and techniques that could enhance the non-stick plates’ performance or even extend their lifespan. This dedication to innovation means that the factory is always one step ahead in the competitive cookware market.

Safety is paramount in this factory. The use of non-toxic materials and the implementation of strict health and safety protocols ensure that workers are protected and the products are free from contaminants. Regular training sessions keep the staff updated on the latest safety standards, creating a secure environment for everyone involved.

As the ceramic coated non-stick plates are packaged, a final quality assurance check is conducted. Each plate is carefully inspected for any defects, and only those that meet the factory’s stringent criteria are allowed to proceed to the distribution center. This attention to detail ensures that the consumer receives a product that is not just functional but also a testament to the factory’s commitment to excellence.

The factory’s state-of-the-art facilities and the passion of its employees are a testament to the fact that ceramic coated non-stick plates are not just a product; they are a game-changer. By combining technological advancements with a relentless pursuit of quality, this factory is not only revolutionizing the cookware industry but also setting the stage for what future kitchenware will look like.

In the heart of the bustling industrial landscape, there lies a factory that has revolutionized the ceramic coated non-stick plates market. This factory stands out not just for its sleek design but for the cutting-edge innovations that it brings to the table. Let’s delve into what truly sets this facility apart.

The factory boasts state-of-the-art machinery that not only enhances production efficiency but also ensures the highest quality standards. The automated systems are designed to minimize human error and maximize precision, creating a seamless production line that churns out thousands of ceramic coated non-stick plates every day.

One innovation that has caught the attention of industry experts is the development of a proprietary ceramic coating formula. This formula is a blend of natural, non-toxic materials that offer superior non-stick properties compared to traditional coatings. The factory’s chemists have meticulously crafted this mixture to be durable, heat-resistant, and safe for everyday use.

Another standout feature is the factory’s commitment to sustainability. The manufacturing process is designed to be eco-friendly, with a focus on reducing waste and energy consumption. Advanced recycling techniques are employed to repurpose materials, and the factory even uses renewable energy sources to power its operations.

Inside the factory, the workflow is a marvel of modern engineering. The plates are crafted with precision, starting from the selection of high-quality steel substrates. These substrates are then carefully coated with the special ceramic mixture, ensuring a uniform and robust layer that will not flake or peel over time.

The coating process itself is a testament to the factory’s innovation. The application of the ceramic coating involves a series of high-temperature ovens that cure the coating to perfection. This unique curing technique guarantees that the non-stick surface is not only non-porous but also scratch-resistant, making the plates durable enough for everyday cooking tasks.

What truly sets this factory apart is its focus on research and development. A dedicated team of scientists and engineers is constantly experimenting with new materials and methods to push the boundaries of what’s possible in ceramic coated cookware. This relentless pursuit of innovation means that the factory is always at the forefront of new technological breakthroughs.

One such innovation is the introduction of a unique pattern on the ceramic surface, which improves heat distribution and reduces sticking. This design is a direct result of extensive testing and feedback from professional chefs and home cooks alike. The factory’s willingness to listen to its customers and adapt its products accordingly is a testament to its customer-centric approach.

Additionally, the factory has implemented a rigorous quality control process that involves multiple stages of inspection. Each plate is checked for any defects, and only those that meet the highest standards are released for packaging. This commitment to quality ensures that customers receive a product that they can trust.

The factory’s innovations don’t stop at the product itself. It has also developed a range of accessories that complement the ceramic coated non-stick plates. These include specialized tools designed to make cooking easier and more enjoyable, such as ergonomic spatulas and innovative whiskers that reduce the need for scraping the surface.

Moreover, the factory has taken steps to ensure that its employees are well-trained and equipped with the latest knowledge in the industry. Continuous education programs are in place, ensuring that the workforce remains at the top of their game and capable of handling the most advanced manufacturing processes.

In the world of ceramic coated non-stick plates, this factory is a beacon of innovation and quality. Its dedication to pushing the boundaries of what’s possible in cookware design has not only set it apart from competitors but has also elevated the entire industry. From the development of a revolutionary ceramic coating to the introduction of eco-friendly practices and customer-centric designs, this factory is not just a manufacturer—it’s a pioneer in the field.

In the ever-evolving landscape of kitchenware, market trends and consumer preferences have shifted significantly, especially in the realm of ceramic coated non-stick plates. These shifts are driven by a variety of factors, including health concerns, environmental awareness, and the demand for convenience.

Consumers are increasingly seeking cookware that not only performs well but also aligns with their values and lifestyle choices. Here are some key trends and preferences shaping the market:

Health and SafetyThe rise of health-conscious consumers has led to a preference for cookware that is free from harmful chemicals like PFOA and PTFE, which were traditionally used in non-stick coatings. Ceramic coatings have emerged as a safer alternative, offering a non-toxic option that appeals to those who want to avoid the potential risks associated with traditional non-stick surfaces.

Eco-Friendly MaterialsWith growing environmental concerns, eco-conscious consumers are gravitating towards cookware made from sustainable materials. Ceramic coated non-stick plates often come with a green story, as they are typically made from natural clay and are recyclable, which is a strong selling point for environmentally aware shoppers.

Versatility and DurabilityModern cooks demand versatility in their kitchenware, and ceramic coated non-stick plates deliver. They are suitable for a wide range of cooking techniques, from searing to simmering, and their durability means they can withstand the rigors of everyday use without wearing down. This dual appeal has made them a favorite among busy home chefs and professional cooks alike.

Easy Cleaning and MaintenanceOne of the standout features of ceramic coated non-stick plates is their ease of cleaning. The non-stick surface reduces the need for excessive oil or butter, making dishes easier to clean off. This convenience is a major draw for consumers who prefer spending less time on dishes and more time enjoying their meals.

Style and DesignCookware that doesn’t just work well but also looks good is becoming increasingly popular. Ceramic coatings come in a variety of colors and finishes, allowing consumers to express their personal style in the kitchen. The aesthetic appeal of these plates is not just about looks; it’s about enhancing the overall kitchen experience.

Price SensitivityWhile high-quality ceramic coated non-stick plates can be more expensive than their traditional counterparts, consumers are often willing to pay a premium for the peace of mind and long-term savings that come with reduced maintenance and a longer lifespan. However, there’s also a growing segment of budget-conscious consumers who are looking for affordable yet reliable options.

Brand Trust and CertificationsAs consumers become more educated about the products they purchase, they are also looking for brands they can trust. Certifications from reputable organizations, such as the FDA or NSF, can be a deciding factor in the purchasing decision. Brands that invest in quality assurance and display these certifications are more likely to resonate with consumers.

Social Media and Influencer EndorsementsThe power of social media and influencer endorsements cannot be overstated. Consumers are often influenced by what they see on their favorite social platforms, and positive reviews from influencers can significantly impact purchasing decisions. Ceramic coated non-stick plate brands that leverage social media effectively can tap into this powerful marketing channel.

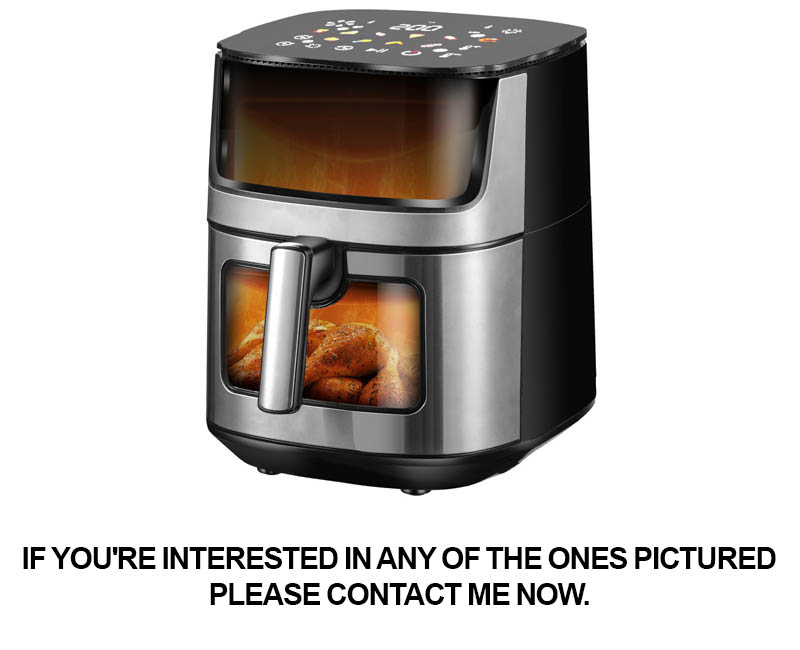

Innovation in Cooking TechniquesThe popularity of cooking shows and cooking techniques such as sous-vide and air frying has sparked an interest in cookware that can handle these new methods. Ceramic coated non-stick plates are often up to the challenge, making them a favorite among enthusiasts of modern cooking techniques.

Global Market ExpansionThe demand for ceramic coated non-stick plates is not limited to a single region; it’s a global trend. As more consumers around the world become aware of the benefits of these products, the market is expanding, offering new opportunities for manufacturers and retailers.

These market trends and consumer preferences paint a picture of a changing landscape in the kitchenware industry. Ceramic coated non-stick plates are not just a product; they are a symbol of the evolving values and needs of consumers who are seeking safer, healthier, and more stylish solutions for their cooking needs.

The ceramic coated non-stick plates factory has become a hub of innovation, pushing the boundaries of traditional cookware. Let’s delve into some of the key aspects that make these factories stand out.

Advanced Coating TechniquesThese factories have invested heavily in state-of-the-art coating techniques. The process involves applying a layer of ceramic coating onto the surface of the cookware, which is then baked at high temperatures to create a durable and non-stick finish. This method ensures that the cookware not only performs well but also maintains its quality over time.

Eco-Friendly ProductionEco-consciousness is at the heart of these factories’ operations. They prioritize the use of environmentally friendly materials and production methods. From sourcing raw materials to minimizing waste during the manufacturing process, these factories are committed to reducing their carbon footprint and promoting sustainability.

Customization and PersonalizationUnderstanding the diverse needs of consumers, these factories offer a wide range of cookware options. From different sizes and shapes to unique colors and patterns, the ability to customize products has become a hallmark of these factories. This approach caters to the personal preferences of consumers, making cookware not just a functional item but also a personal statement.

Cutting-Edge Research and DevelopmentInnovation is a driving force in these factories. Continuous research and development efforts ensure that new technologies and materials are constantly being explored. This proactive approach allows the factories to stay ahead of the curve and introduce new features and benefits to their products.

Quality Control and AssuranceA rigorous quality control process is in place to ensure that each piece of cookware leaving the factory meets the highest standards. From the initial selection of raw materials to the final inspection, every step is carefully monitored to guarantee the longevity and performance of the products.

Global ReachThese factories have expanded their operations globally, reaching customers in various countries across Europe and the Americas. This global footprint is a testament to the quality and demand for their ceramic coated non-stick plates.

Training and DevelopmentThe workforce in these factories undergoes regular training and development programs. By investing in their employees’ skills and knowledge, these factories maintain a high level of expertise throughout their operations.

Customer Feedback and AdaptationThese factories take customer feedback seriously, using it as a tool to improve their products and services. By listening to what consumers have to say, the factories are able to adapt and evolve, ensuring that their offerings align with market trends and consumer preferences.

Strategic PartnershipsCollaborating with industry leaders and material suppliers, these factories have formed strategic partnerships that enhance their product offerings. These alliances provide access to cutting-edge materials and technologies, further distinguishing the factories from their competitors.

Expansion into New MarketsThe factories are continuously seeking opportunities to expand into new markets. By identifying emerging trends and understanding regional preferences, they are able to adapt their products to cater to a wider audience.

Emphasis on Health and SafetyHealth and safety are paramount in these factories. Strict protocols are followed to ensure that products are safe for consumers to use, and that the manufacturing process itself does not pose any risks to employees.

Technological IntegrationIntegrating technology into the production line has significantly improved efficiency and productivity. Automation and digital systems are used to monitor and optimize every aspect of the manufacturing process.

In summary, the ceramic coated non-stick plates factory is a beacon of innovation and excellence. Their commitment to quality, sustainability, and customer satisfaction is reflected in their cutting-edge technologies, eco-friendly practices, and the continuous improvement of their product line.

The European and American markets have been witnessing a significant shift in the kitchenware industry, particularly with the advent of ceramic coated non-stick cookware. This transformation is marked by various factors that are reshaping consumer behavior and market dynamics.

The ceramic coating technology has revolutionized the non-stick cookware landscape by offering several advantages over traditional coatings like Teflon. This section delves into the impact of ceramic coated non-stick plates on both the European and American markets.

One of the most notable impacts is the increase in demand for ceramic coated non-stick plates. Consumers in both regions are increasingly gravitating towards cookware that promises healthier cooking with fewer toxins. The rise of health consciousness has prompted a significant shift in the market, with sales of ceramic coated products soaring.

In Europe, the market for ceramic coated non-stick plates has seen a steady growth over the past few years. This is attributed to the stringent regulations on chemical emissions and the growing preference for eco-friendly products. The European consumer is more aware of the potential health risks associated with conventional non-stick coatings and is actively seeking alternatives. This has led to a surge in the popularity of ceramic cookware, which is perceived as a safer and more sustainable option.

Similarly, in the American market, there has been a noticeable change in consumer preferences. The trend towards clean eating and the quest for non-toxic cooking surfaces has pushed ceramic coated non-stick plates to the forefront. The demand for cookware that does not release harmful chemicals, especially when overheated, has been on the rise. This has been further fueled by celebrity endorsements and health experts advocating for the use of ceramic coated cookware.

Another significant impact on both markets is the rise of smart technology integrated into ceramic coated non-stick plates. Brands are now offering cookware that not only boasts health benefits but also provides convenience. Features such as induction compatibility, temperature control, and built-in cooking timers have become popular, especially among tech-savvy consumers. This has led to an increase in the average price point of ceramic coated non-stick plates, as consumers are willing to pay a premium for innovative technology.

Moreover, the market for ceramic coated non-stick plates has seen an expansion in the variety of designs and materials. Manufacturers are now experimenting with different ceramic formulations to enhance durability and performance. The introduction of new patterns, colors, and materials has appealed to a broader audience, including those who prefer a more stylish kitchen aesthetic. This has contributed to a more competitive market, with manufacturers constantly trying to outdo each other in terms of product innovation and design.

The impact of ceramic coated non-stick plates is also seen in the retail sector. Stores are adapting their inventory to cater to the growing demand for these products. Supermarkets, specialty kitchenware stores, and online retailers are all experiencing increased sales, with ceramic coated non-stick plates often featured as a highlight or a part of promotional campaigns.

In Europe, the market is further influenced by the rise of direct-to-consumer brands that offer ceramic coated cookware. These brands, with their focus on sustainability and ethical sourcing, are gaining traction among environmentally conscious consumers. The European market’s openness to new and innovative brands has facilitated the entry of these direct-to-consumer companies, which are disrupting traditional distribution channels.

The American market, while more established in terms of ceramic coated cookware sales, is not immune to the changing landscape. The increasing competition and the evolving consumer preferences are pushing manufacturers and retailers to continuously innovate and adapt. The market is becoming more segmented, with niche markets emerging for specific consumer groups, such as athletes seeking cookware that promotes nutrient-rich meals or busy professionals looking for easy-to-clean, quick-cooking options.

In conclusion, the ceramic coated non-stick plate market has had a profound impact on both the European and American markets. The shift towards healthier living, environmental consciousness, and technological advancements has created a demand for a product that offers a balance between health, sustainability, and convenience. As manufacturers continue to push the boundaries of innovation, the future of ceramic coated cookware looks promising, with the European and American markets leading the charge.

In the world of kitchenware, the commitment to quality and environmental responsibility has become more than just a buzzword; it’s a cornerstone of success. For the ceramic coated non-stick plates factory, maintaining high standards and embracing eco-friendly practices is not just about staying ahead of the curve—it’s about crafting a legacy that resonates with both consumers and the planet.

The factory’s approach to quality is meticulous, from the sourcing of raw materials to the final inspection of each product. They understand that the non-stick coating is the heart of their product, and thus, they invest in premium-grade ceramics that are not only durable but also free from harmful chemicals like PFOA and PTFE. This dedication to purity ensures that every plate they produce is not just a tool for cooking but also a symbol of health and safety.

Environmental responsibility is deeply woven into the factory’s operations. They’ve implemented a series of initiatives to reduce their carbon footprint. One such initiative is the use of renewable energy sources, such as solar panels, to power their manufacturing facilities. This move not only slashes energy costs but also significantly cuts down on greenhouse gas emissions.

The factory also focuses on water conservation. Advanced recycling systems are in place to treat and reuse water, minimizing waste and ensuring that every drop is used efficiently. Additionally, the factory has adopted a recycling program for packaging materials, ensuring that the materials used to protect their products are themselves sustainable.

In terms of materials, the factory has made a conscious effort to use recycled and recyclable materials wherever possible. This extends to the packaging itself, which is designed to be easily recyclable and to minimize waste. By doing so, they’re not just reducing their impact on the environment but also setting an example for their customers to follow.

The factory’s commitment to quality and the environment doesn’t stop at their own operations. They’ve also established a rigorous training program for their workforce, emphasizing the importance of sustainability and the role each employee plays in maintaining these high standards. This culture of environmental stewardship trickles down to every aspect of their operations, from the way products are designed to the way they’re disposed of at the end of their life cycle.

When it comes to the end product, the factory understands that the consumer is increasingly conscious of the environmental impact of their purchases. They’ve responded by creating a range of ceramic coated non-stick plates that are not only durable and easy to clean but also designed with the environment in mind. The plates are lightweight, making them easier to transport and handle, and they come with a lifespan that far exceeds that of traditional non-stick cookware.

The factory also offers a range of eco-friendly accessories, such as bamboo utensils and stainless steel strainers, that complement their ceramic coated non-stick plates. These accessories are designed to be used alongside the plates, extending their longevity and further reducing the need for disposable items.

Moreover, the factory actively participates in community initiatives and partnerships that support environmental conservation. They’ve joined local recycling programs and collaborate with non-profit organizations to promote sustainability education. By doing so, they’re not only contributing to the health of the environment but also fostering a sense of responsibility among their customers.

In a market where consumers are more likely to reward brands that align with their values, the ceramic coated non-stick plates factory stands out. Their commitment to quality and environmental responsibility has turned them into a leader in the industry, and their products are a testament to their dedication to making a positive impact.

The factory’s approach to quality and sustainability is a double-edged sword. On one side, it ensures that their products meet the highest standards, providing customers with reliable and long-lasting cookware. On the other side, it addresses the growing concern for the environment, offering a solution that is both eco-friendly and practical.

In conclusion, the ceramic coated non-stick plates factory’s commitment to quality and environmental responsibility is not just a strategy; it’s a philosophy that drives every aspect of their business. By doing so, they’re not only setting a new benchmark in the industry but also inspiring others to follow suit. In a world where the stakes are high and the future is uncertain, their approach is a shining example of how businesses can thrive while also being stewards of the planet.

In recent years, the demand for ceramic coated non-stick plates has surged, reshaping the kitchenware industry. These innovative cookware pieces offer a myriad of benefits that cater to both the environmental and health-conscious consumer. As we delve into the future of ceramic coated non-stick plates, several key trends and potential developments emerge, painting a picture of a product poised to continue its ascent in the market.

The popularity of ceramic coatings is largely due to their non-toxic nature. Unlike traditional non-stick coatings, which often contain harmful chemicals like PFOA and PTFE, ceramic coatings are free from these toxic substances. This has resonated with consumers who are increasingly concerned about the health implications of their cooking habits, leading to a shift towards safer alternatives.

The versatility of ceramic coated non-stick plates is another factor contributing to their growing appeal. These plates are not only excellent for cooking a wide range of dishes but also maintain their non-stick properties even after years of use. This longevity is a significant draw for environmentally conscious consumers who seek to reduce kitchen waste and extend the life of their cookware.

In terms of design, ceramic coated non-stick plates often come in a variety of colors and finishes, offering consumers a chance to personalize their kitchenware. This aesthetic appeal caters to those who appreciate the importance of a visually pleasing kitchen environment.

The manufacturing process of ceramic coated non-stick plates is also evolving. Factories are investing in advanced technology to ensure the highest quality coatings. These include robotic systems for precise application of the ceramic particles and high-temperature curing processes that strengthen the bond between the ceramic and the plate surface.

In the realm of sustainability, ceramic coated non-stick plates have a clear advantage. They are more durable than traditional non-stick cookware, which means fewer replacements are needed over time. This reduces the environmental impact of manufacturing and disposal. Additionally, the lack of harmful chemicals in ceramic coatings means that the plates can be recycled or composted at the end of their life cycle, further reducing their environmental footprint.

Market research indicates that the demand for ceramic coated non-stick plates is on the rise globally. In Europe, the market is being driven by health concerns and the growing preference for eco-friendly products. The American market, on the other hand, is seeing a surge in demand due to the increased awareness of the dangers of traditional non-stick coatings and the rising popularity of minimalist kitchen aesthetics.

The future of ceramic coated non-stick plates looks promising, with several exciting developments on the horizon. One such development is the introduction of ceramic coatings that are even more durable and resistant to scratching and wear. This will appeal to consumers who are looking for cookware that can withstand heavy use.

Another trend is the integration of smart technology into ceramic coated non-stick plates. Imagine a cookware piece that can monitor cooking temperatures and times, ensuring perfect results every time. Such innovations would not only enhance the cooking experience but also cater to the tech-savvy consumer who values convenience and efficiency.

The future also holds the potential for ceramic coatings to be applied to a wider range of cookware products, including pots, pans, and even bakeware. This expansion would further solidify ceramic coated non-stick plates as a must-have item in modern kitchens.

Lastly, the continued focus on sustainability and environmental responsibility will play a crucial role in shaping the future of ceramic coated non-stick plates. As consumers become more aware of the importance of reducing waste and protecting the planet, they will seek out products that align with these values. The industry will need to ensure that the production processes remain eco-friendly and that the products are designed for a circular economy.

In conclusion, the future of ceramic coated non-stick plates is bright, with a strong emphasis on health, sustainability, and innovation. As the market continues to grow, we can expect to see even more exciting advancements that will make these plates an indispensable part of modern kitchens worldwide.

The shift towards ceramic-coated non-stick plates is not just a fleeting trend; it’s a testament to the evolving demands of consumers and the relentless pursuit of innovation. These plates are becoming a staple in kitchens across the globe, and their impact is profound. The reasons for their staying power are numerous, from their health benefits to their durability and eco-friendly nature.

Health-conscious consumers are increasingly looking for alternatives to traditional non-stick coatings, which can release harmful chemicals when overheated. Ceramic coatings, on the other hand, are free from PFOA and PTFE, two chemicals linked to potential health risks. This shift in preference is a clear indicator of the market’s move towards safer, more sustainable options.

Durability is another key factor. Ceramic coatings are designed to withstand higher temperatures than their chemical counterparts, making them less prone to scratching and peeling. This longevity means fewer replacements, which in turn reduces waste and the carbon footprint associated with manufacturing and disposing of cookware.

The environmental angle is also compelling. Ceramic-coated non-stick plates are often made from recycled materials, and their lower environmental impact during production and use resonates with eco-conscious consumers. The emphasis on sustainability is not just a marketing ploy; it’s a reflection of the values that are shaping the future of the cookware industry.

In the European and American markets, where health and environmental concerns are paramount, ceramic-coated non-stick plates have gained significant traction. The European market, in particular, has shown a preference for cookware that is not only functional but also aesthetically pleasing. The sleek, modern design of ceramic-coated plates appeals to this demographic, making them a popular choice for both home cooks and professional chefs.

In the United States, the emphasis on convenience and health has propelled the growth of ceramic-coated non-stick plates. The ease of cooking without the need for excessive oil or butter, coupled with the ease of cleaning, has made these products a hit among busy individuals and families. The market data reflects this trend, with sales figures soaring year after year.

The data-driven insights into consumer behavior and market trends are compelling. Sales reports indicate a steady increase in the demand for ceramic-coated non-stick plates, with a particular surge in popularity during the past few years. This upward trajectory is expected to continue, driven by the growing awareness of health and environmental issues.

The integration of technology into the manufacturing process has also played a role in the success of ceramic-coated non-stick plates. Advanced coatings techniques ensure that the ceramic layer is applied evenly and uniformly, resulting in a non-stick surface that is as effective as it is durable. This technological advancement has not only improved the quality of the product but has also opened up new possibilities for design and customization.

Looking ahead, the future of ceramic-coated non-stick plates looks bright. The industry is poised to explore new materials and manufacturing techniques that could further enhance the performance and longevity of these products. Innovations in materials science may lead to coatings that are even more heat-resistant and scratch-proof, while still maintaining their non-stick properties.

Additionally, there is a growing trend towards personalized cookware. Consumers are looking for products that not only meet their functional needs but also reflect their personal style. The ceramic-coated non-stick plate market is responding to this demand by offering a wide range of colors and designs, allowing customers to choose cookware that complements their kitchen decor.

In conclusion, ceramic-coated non-stick plates are here to stay due to their numerous advantages. Their health benefits, durability, eco-friendly nature, and growing market demand ensure their continued popularity. As the industry evolves, so too will the products, offering consumers even more reasons to choose ceramic-coated non-stick plates over other options. The future is bright, and these plates are set to be a staple in kitchens for years to come.