Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the culinary world continues to evolve, air fryers have emerged as a game-changer in kitchen appliances. These innovative devices are not just redefining how we cook, but also reshaping the landscape of the kitchen appliance sector. With the demand for healthier cooking options on the rise, the air fryer market is experiencing a surge in popularity. This article delves into the exciting world of air fryer Original Design Manufacturers (ODMs), exploring the benefits of choosing China for your ODM needs, the importance of innovative design, the intricate development process, market trends in the EU and US, ensuring quality assurance, customization for brand fit, and the success story of a 30-day air fryer ODM project. By the end, we aim to provide you with a comprehensive understanding of the air fryer market and empower you to navigate it with confidence.

The air fryer has quietly revolutionized the way we cook, becoming a staple in modern kitchens worldwide. Once a niche product, it has now transformed into a must-have gadget for health-conscious and convenience-seeking home chefs. Let’s dive into the fascinating world of the air fryer phenomenon.

Once confined to the realms of deep-fat fryers and their calorie-laden counterparts, the air fryer has emerged as a hero in the fight against obesity and heart disease. By using hot air to circulate around food, it reduces the need for oil, thus cutting down on fat content while still delivering that crispy texture we all love. This clever invention has not only changed the way we think about frying but has also sparked a surge in popularity across various demographics.

The air fryer’s rise to fame can be attributed to several factors. First and foremost, the health benefits are undeniable. As more people become aware of the risks associated with excessive oil consumption, they are turning to air fryers as a healthier alternative. Secondly, the convenience of air frying is hard to beat. With minimal cleanup and a quick cooking time, it’s no wonder that busy professionals and families are embracing this kitchen marvel.

The versatility of the air fryer is another reason for its meteoric rise. It can cook a wide range of foods, from chicken wings and French fries to vegetables and even desserts. This versatility has made it a staple in both home and commercial kitchens, from the smallest apartments to the largest restaurants.

In recent years, the air fryer has also become a symbol of innovation in the kitchen appliance industry. Brands are constantly pushing the boundaries, introducing new features and functionalities that cater to the evolving needs of consumers. Smart air fryers with digital controls, preset cooking programs, and even voice assistants are now becoming the norm, further solidifying the air fryer’s status as a modern kitchen essential.

The air fryer has also become a cultural phenomenon. From social media influencers to cooking shows, the air fryer is often featured as a go-to tool for creating mouthwatering dishes with minimal effort. This has not only generated a sense of community among users but has also sparked a wave of creativity in cooking, as people experiment with new recipes and techniques.

In the culinary world, the air fryer has also become a game-changer for chefs and food enthusiasts alike. It allows for the creation of dishes that were once thought to be impossible without the use of oil, such as crispy tofu and air-fried seafood. This has opened up a world of possibilities for those looking to explore new flavors and textures.

Moreover, the air fryer has become a symbol of sustainability. By reducing the need for oil, it helps to conserve resources and minimize environmental impact. This eco-friendly aspect has resonated with consumers who are increasingly conscious of their carbon footprint and the importance of making sustainable choices in their daily lives.

As the air fryer continues to gain traction, it’s clear that this phenomenon is here to stay. With ongoing advancements in technology and a growing demand for healthier, more convenient cooking options, the air fryer is poised to become an even more integral part of our culinary landscape. Whether you’re a seasoned chef or a beginner home cook, the air fryer has something to offer everyone, making it an indispensable tool in the modern kitchen.

In the ever-evolving world of kitchen appliances, a new trend has emerged that’s transforming how we cook and eat. The rise of Original Design Manufacturers (ODMs) in the kitchen appliance sector has been nothing short of revolutionary. These specialized firms are not just producing products; they are shaping the future of culinary innovation.

ODMs have become the backbone of the kitchen appliance industry, offering a unique blend of creativity and expertise that has propelled the sector to new heights. By focusing on design and development, these companies have been able to cater to the ever-changing demands of consumers, creating products that are not only functional but also stylish and user-friendly.

The shift towards ODMs in the kitchen appliance sector is a testament to the industry’s maturation. In the past, manufacturers were primarily focused on mass production and cost reduction. However, as consumers became more discerning, the demand for unique, high-quality appliances grew. ODMs have filled this void, acting as a bridge between the end-users and the manufacturing process.

One of the key advantages of ODMs is their ability to offer tailored solutions. They work closely with brands to understand their specific needs and market requirements, ensuring that the final product aligns with the brand’s image and the consumers’ expectations. This personalized approach has allowed ODMs to innovate and push the boundaries of what is traditionally considered a kitchen appliance.

The rise of ODMs has also been fueled by the globalization of the kitchen appliance market. With the world becoming more interconnected, companies are looking for partners who can help them enter new markets with ease. ODMs have the global reach and knowledge to navigate the complexities of international trade, from regulatory compliance to cultural nuances.

Another crucial factor in the rise of ODMs is the emphasis on sustainability and eco-friendliness. Consumers are increasingly concerned about the environmental impact of their purchases, and ODMs are responding by designing appliances that are energy-efficient and made with sustainable materials. This focus on sustainability not only appeals to environmentally conscious consumers but also positions brands as leaders in responsible innovation.

In terms of technology, ODMs are at the forefront of integrating cutting-edge features into kitchen appliances. Smart appliances with connectivity options, such as Wi-Fi-enabled ovens or induction cooktops with precise temperature control, are becoming more common. These advancements are not just about convenience; they are about enhancing the overall cooking experience and making appliances more adaptable to individual preferences.

Moreover, ODMs are adept at staying ahead of market trends. They closely monitor consumer behavior, social media, and emerging technologies to anticipate future needs. This forward-thinking approach allows them to develop products that are not only relevant today but also poised to become tomorrow’s standards.

The collaboration between ODMs and brands is a symbiotic relationship. ODMs provide the technical and design know-how, while brands bring their market expertise and consumer insights. This partnership has led to a surge in product innovation, with a multitude of new kitchen appliances hitting the market every year.

From compact countertop appliances to integrated kitchen systems, ODMs have played a pivotal role in expanding the scope and capabilities of kitchen appliances. They have brought to life products that were once just ideas, turning concepts into reality. This transformation has not only made cooking more enjoyable but has also redefined the kitchen itself.

In conclusion, the rise of ODMs in the kitchen appliance sector is a reflection of the industry’s commitment to innovation, customization, and sustainability. As the demand for unique, high-quality appliances continues to grow, ODMs are set to remain at the forefront, driving the future of kitchen appliance design and development.

China has become a powerhouse in the kitchen appliance sector, and for good reason. When considering Original Design Manufacturing (ODM) for your air fryer, there are several compelling reasons why China stands out as the preferred destination.

Vast Manufacturing ExpertiseThe manufacturing sector in China is renowned for its scale and expertise. With decades of experience in producing a wide array of electronics and appliances, the country boasts a workforce skilled in precision engineering, robotics, and automation. This vast experience translates into a deep understanding of the production process, from sourcing materials to the assembly line, ensuring that air fryer ODM projects are executed with precision and efficiency.

Cost-Effective ProductionCost is often a major consideration for businesses looking to outsource manufacturing. China offers a cost-effective solution due to its lower labor costs compared to other developed nations. This allows for competitive pricing without compromising on quality. The economies of scale in Chinese manufacturing facilities mean that production costs can be further reduced, making it an attractive option for businesses aiming to maximize profit margins.

Extensive Supply ChainThe supply chain in China is incredibly robust and well-established. Access to a vast network of suppliers and vendors ensures that materials and components for air fryer production are readily available. This streamlined supply chain reduces lead times and enhances the efficiency of the manufacturing process. Additionally, the availability of specialized components and parts in China can lead to innovative design possibilities.

Quality ControlDespite the focus on cost-effectiveness, Chinese manufacturers prioritize quality control. With stringent regulations and the implementation of international quality standards, the products that emerge from Chinese factories are held to high standards. This is particularly important for air fryers, which must meet safety and performance expectations to gain consumer trust.

Innovation and R&DChina is not just a manufacturing hub; it is also a hotbed of innovation and research and development (R&D). Local manufacturers often collaborate with R&D centers and universities to push the boundaries of what is possible in air fryer design and technology. This focus on innovation means that your air fryer ODM project can benefit from cutting-edge features and materials that might not be as accessible in other regions.

Diverse Range of ManufacturersThe Chinese market is home to a diverse array of manufacturers, each with its unique strengths. Whether you’re looking for a high-end, premium air fryer or a budget-friendly model, there is a manufacturer out there that can cater to your specific needs. This variety allows for flexibility in choosing the right partner for your project.

Global ReachChinese manufacturers are well-versed in exporting to international markets. They understand the nuances of global trade and are equipped to handle the complexities of shipping, customs, and logistics. This means that your air fryer ODM project can be managed seamlessly from design to delivery, ensuring that your product reaches customers around the world with ease.

SustainabilityWith growing environmental concerns, China has been investing heavily in sustainable manufacturing practices. Many manufacturers are adopting green technologies and processes to reduce their carbon footprint. This focus on sustainability can be a significant advantage for brands looking to align with eco-friendly consumer values.

Customization and FlexibilityChinese manufacturers offer a high level of customization, allowing brands to tailor air fryers to specific market needs. From design modifications to branding and packaging, the flexibility to adapt the product to various market segments is a key advantage of choosing China for ODM.

In summary, China’s position as a leading player in the kitchen appliance sector, coupled with its manufacturing prowess, cost-effectiveness, and innovative approach, makes it an ideal choice for air fryer ODM needs. The combination of a vast manufacturing ecosystem, quality control, and a commitment to innovation ensures that brands can bring their air fryer visions to life with confidence.

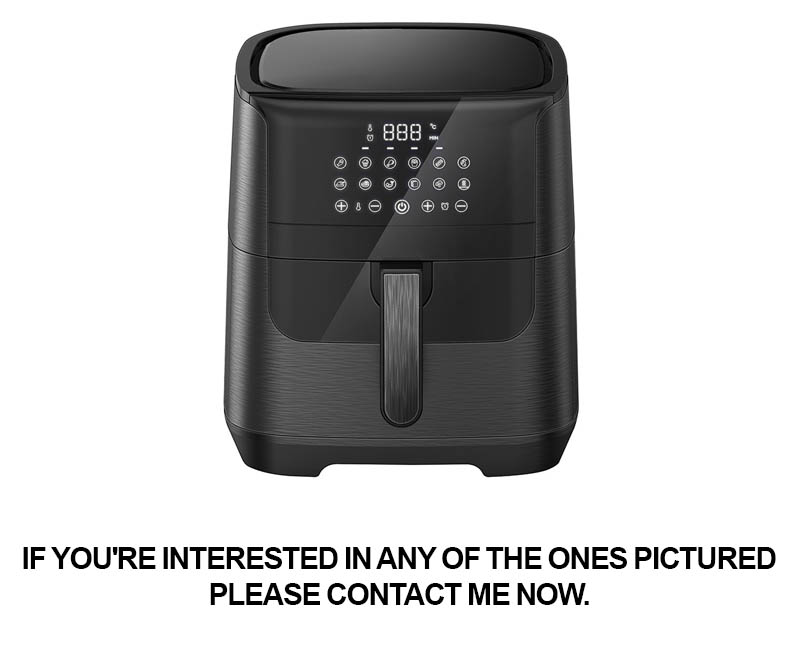

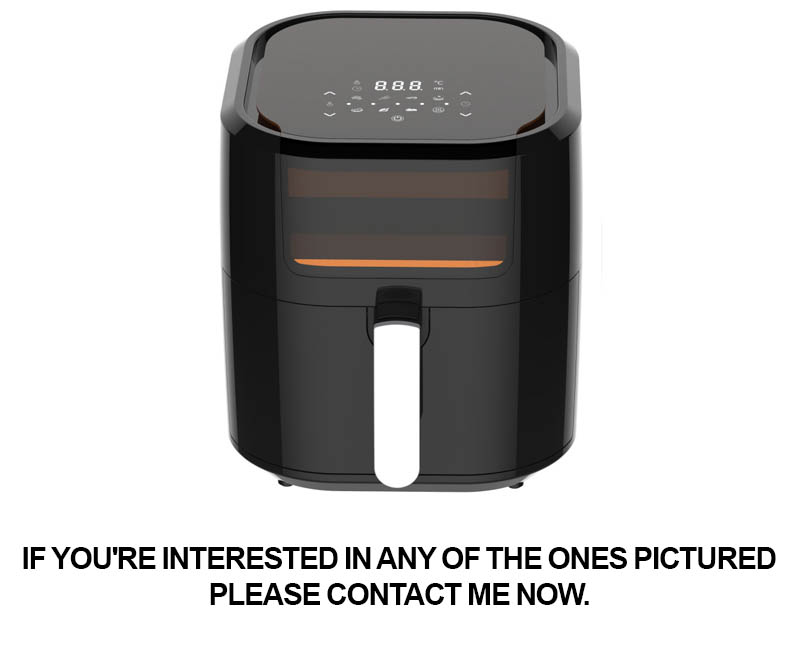

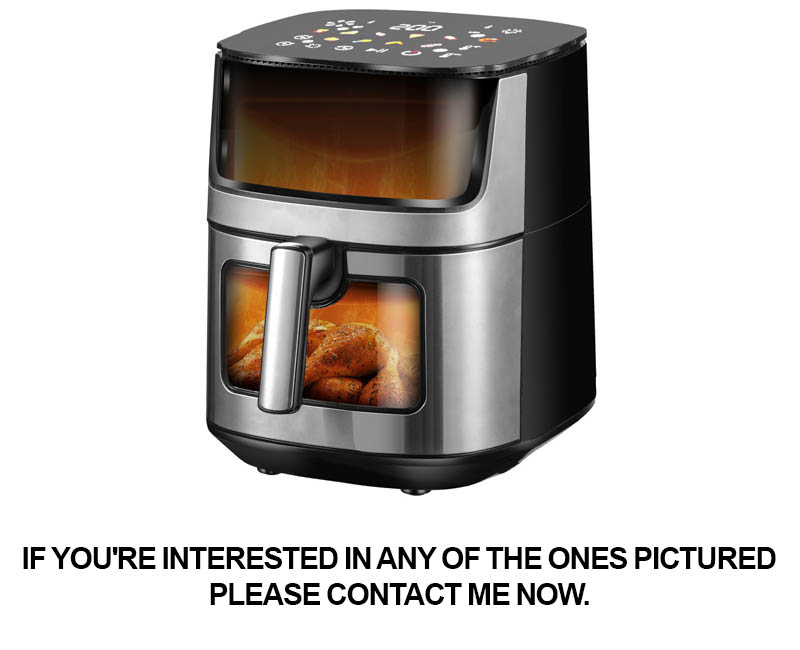

In the ever-evolving world of kitchen appliances, the air fryer has emerged as a revolutionary player, transforming how we cook and eat. But it’s not just the existing models that are making waves; it’s the innovative ideas that are shaping the next generation of air fryers. Here are some of the groundbreaking concepts that are poised to redefine the market:

The first notable innovation is the integration of smart technology. Modern air fryers are not just about cooking; they’re about connectivity. Imagine an air fryer that can be controlled via a smartphone app, allowing you to monitor and adjust settings from anywhere. This not only adds convenience but also ensures that your food is cooked to perfection, regardless of your location.

Another area of innovation is the focus on health and wellness. Air fryers are already a healthier alternative to traditional frying methods, but the next generation is taking it a step further. We’re seeing designs that incorporate adjustable oil levels, making it possible to use even less oil for cooking. Additionally, some models are introducing self-cleaning functions, reducing the need for manual cleaning and promoting a more hygienic cooking environment.

The aesthetics of air fryers are also undergoing a transformation. No longer are they just utilitarian appliances; they are becoming statement pieces for your kitchen. Manufacturers are experimenting with sleeker designs, incorporating materials like stainless steel and glass, and even introducing colors and finishes that complement a variety of kitchen decors.

One of the most exciting innovations is the expansion of cooking capabilities. The next generation of air fryers is not just limited to frying; they are multifunctional appliances that can bake, roast, and even dehydrate. This versatility means that you can use a single appliance to perform multiple cooking tasks, saving space and simplifying meal preparation.

Customization is another key aspect that’s gaining traction. Some air fryer models are being designed with interchangeable components, allowing users to adapt the appliance to their specific needs. For example, different basket sizes or even a steaming tray could be included, making the air fryer suitable for everything from crispy French fries to delicate fish fillets.

Sustainability is also playing a role in the development of new air fryer ideas. We’re seeing an increase in the use of eco-friendly materials and energy-efficient designs. From biodegradable components to energy-saving modes, these air fryers are not only good for your health but also for the planet.

Safety features are being enhanced as well. Advanced overheating protection, child lock mechanisms, and automatic shut-off functions are becoming standard in new air fryer models. These features provide peace of mind, knowing that your appliance is safe to use, even when you’re not at home.

Lastly, the rise of social cooking has influenced the design of air fryers. Some models are being developed with built-in video conferencing capabilities, allowing you to cook alongside friends or family members, even if they’re in a different part of the world. This is particularly appealing for those who enjoy cooking together but are geographically separated.

In conclusion, the next generation of air fryers is being shaped by a myriad of innovative ideas. From smart technology and health-focused features to aesthetic appeal and environmental considerations, these appliances are not just cooking devices; they are becoming an integral part of our daily lives. As the market continues to evolve, we can expect even more creative and functional air fryers that will revolutionize the way we cook and eat.

The development process of an air fryer, from initial design to final production, is a meticulous journey that combines creativity, technical expertise, and a keen eye for market trends. Here’s an inside look at what goes into crafting the next generation of air fryers.

The Conceptualization PhaseThe journey begins with the brainstorming session, where ideas are sketched out on paper or digital platforms. Engineers and designers gather to discuss the latest consumer needs, market demands, and technological advancements. The goal is to conceptualize an air fryer that not only meets these criteria but also stands out in a crowded market.

Iterative DesignOnce the concept is set, the design phase kicks in. This involves sketching out the initial design, which is then refined through a series of iterations. The design team must consider factors such as ease of use, safety, energy efficiency, and the ability to cook a variety of foods. Each iteration brings the design closer to the final product, with adjustments made based on feedback from the team and initial prototypes.

Prototyping and TestingWith the design finalized, the next step is to create a prototype. This is a working model of the air fryer that allows the team to test its functionality and durability. Prototypes are built using 3D printing, metal fabrication, and other prototyping techniques. Rigorous testing is conducted to ensure that the air fryer operates as intended, from the heat distribution to the ease of cleaning.

Functionality and SafetyDuring the development process, functionality and safety are paramount. The air fryer must be capable of reaching the desired cooking temperatures and maintaining them consistently. Safety features, such as overheating protection and non-slip bases, are integrated to prevent accidents. The team also ensures that the product complies with international safety standards, which can vary by region.

Material SelectionChoosing the right materials is crucial for both the performance and the longevity of the air fryer. Materials must be durable, heat-resistant, and easy to clean. The development team works closely with suppliers to select high-quality components that not only meet the product’s requirements but also align with the brand’s image and target price point.

Integration of Smart FeaturesIn today’s market, smart features are becoming increasingly popular. The development process involves integrating technology such as touchscreens, Wi-Fi connectivity, and app integration. These features allow users to control their air fryer remotely, track cooking times, and even receive recipes. The team must ensure that these features are user-friendly and do not compromise the product’s reliability.

User Interface and ExperienceThe user interface (UI) and user experience (UX) are critical to the success of an air fryer. The team designs an intuitive UI that is easy to navigate, with clear icons and simple controls. The UX is designed to be seamless, ensuring that users can achieve their cooking goals with minimal effort. This includes considering the placement of buttons, the size of the display, and the overall layout of the control panel.

Pilot ProductionAfter thorough testing and refinement, the air fryer moves into pilot production. This stage involves producing a small batch of units to test the entire production process. It’s an opportunity to identify any potential issues that may have been overlooked during the development phase. The team monitors the production line, quality control, and supply chain logistics to ensure that everything runs smoothly.

Feedback and Final AdjustmentsOnce the pilot production is complete, the team gathers feedback from both internal testing and external beta testers. This feedback is used to make final adjustments to the design, production process, and user experience. It’s a critical step that ensures the final product meets the highest standards of quality and performance.

Finalizing ProductionWith all adjustments made, the air fryer is ready for full-scale production. The development team works with the manufacturing team to optimize the production process, ensuring efficiency and quality control. They also oversee the implementation of any necessary certifications and compliance measures.

In conclusion, the development process of an air fryer is a complex and multi-faceted endeavor. It requires a combination of innovation, precision, and attention to detail to bring a new product to market that not only meets consumer expectations but also stands out in a competitive landscape.

The European Union (EU) and the United States (US) are two of the world’s largest and most influential markets for consumer electronics, including kitchen appliances. Understanding the trends and opportunities in these regions is crucial for any company looking to succeed in the air fryer ODM (Original Design Manufacturer) space. Here’s a closer look at the market dynamics:

Health and Wellness Trends Driving DemandThe EU and US consumers are increasingly health-conscious, leading to a surge in demand for kitchen appliances that promote healthier cooking methods. Air fryers, with their ability to cook with less oil, have become a popular choice for those looking to reduce fat intake without sacrificing flavor.

Smart Technology IntegrationThere’s a growing trend towards smart kitchen appliances that can be controlled via smartphones or other devices. In the US and EU, consumers are eager to adopt air fryers that come with features like Wi-Fi connectivity, remote monitoring, and customizable cooking programs.

Sustainability and Eco-Friendly DesignsBoth markets are placing a higher value on sustainability. Air fryer manufacturers are responding by focusing on eco-friendly materials, energy-efficient designs, and appliances that are easy to recycle at the end of their life cycle.

Design and AestheticsThe aesthetic appeal of kitchen appliances has become a significant factor in purchasing decisions. In the EU and US, consumers are drawn to air fryers that not only perform well but also complement their kitchen decor. Sleek designs, modern colors, and innovative shapes are becoming key selling points.

Competitive LandscapeThe market is highly competitive, with numerous brands vying for consumer attention. This competition drives innovation and pushes manufacturers to offer unique features and benefits. In the US, brands like Instant Pot and NuWave have already made significant inroads, while in the EU, local brands like Tefal and Russell Hobbs are strong competitors.

Regulatory ComplianceBoth the EU and US have stringent regulations regarding product safety and environmental standards. Companies must ensure that their air fryers comply with these regulations to avoid legal issues and maintain consumer trust.

Distribution ChannelsUnderstanding the distribution channels is essential for market entry. In the US, big-box retailers like Walmart and Costco are major players, while in the EU, online sales through Amazon and local e-commerce platforms are increasingly popular.

Cross-Generational AppealAir fryers are not just a trend among millennials; they have gained popularity across different age groups. The simplicity and convenience of air frying have made it appealing to busy professionals, families, and retirees alike.

Cultural DifferencesWhile the core appeal of air fryers remains consistent across the EU and US, there are cultural nuances to consider. For example, in the US, there’s a strong focus on innovation and technology, while in the EU, there’s a greater emphasis on sustainability and eco-friendliness.

Marketing StrategiesEffective marketing strategies are key to standing out in the crowded market. Brands need to leverage social media, influencer partnerships, and targeted advertising to reach their desired audience. In the US, influencer marketing is particularly effective, while in the EU, traditional media and in-store demonstrations play a larger role.

Product InnovationContinuous innovation is crucial for staying ahead in the market. This includes not only new features but also improvements in durability, ease of use, and cooking performance. Brands that can innovate quickly and effectively will have a competitive edge.

Global Supply ChainGiven the global nature of the kitchen appliance industry, having a robust supply chain is essential. Companies need to ensure they can source components, manage production, and distribute products efficiently to meet the demands of the EU and US markets.

Understanding these trends and opportunities is vital for any company looking to enter or expand in the air fryer ODM market in the EU and US. By aligning with consumer preferences, regulatory requirements, and distribution channels, manufacturers can position themselves for success in these dynamic markets.

In the competitive landscape of kitchen appliances, ensuring quality is paramount. When it comes to meeting international standards, China has emerged as a leading hub for quality assurance in the production of air fryers and other kitchen gadgets. Here’s a closer look at how this process unfolds:

The meticulous attention to detail in Chinese manufacturing is a cornerstone of its reputation for quality. From the selection of raw materials to the final assembly, every step is scrutinized to ensure that the end product meets the highest standards. This commitment to excellence is evident in the adherence to global certifications like ISO 9001, which guarantees a quality management system that is robust and reliable.

In the realm of air fryers, the components are sourced from suppliers who are themselves certified for quality. This includes not just the plastic parts, but also the electrical components, heating elements, and even the cooking baskets. The precision with which these parts are manufactured and tested ensures that the air fryer will perform consistently and safely.

The assembly line is where the magic happens. Workers are trained to a high standard, with each step of the process being carefully monitored. Whether it’s the insertion of electronic components, the application of heat-resistant coatings, or the final checks for functionality, every air fryer is handled with care. This attention to detail minimizes the risk of defects and guarantees a product that is ready to meet the demands of consumers worldwide.

Testing is a critical phase in the quality assurance process. Air fryers are subjected to a battery of tests to ensure they meet safety and performance standards. These tests can include drop tests to simulate handling by consumers, temperature tests to ensure even cooking, and electrical safety checks to prevent any risks of fire or electric shock. The rigorous testing process ensures that only air fryers that are up to par with international standards leave the factory.

Certification bodies play a vital role in validating the quality of Chinese-made air fryers. These independent organizations conduct audits and inspections to verify that the manufacturing processes are in line with international regulations. They also conduct random sampling and testing to ensure that the final product meets the required specifications. The certifications that a product holds are a testament to its quality and can be a significant selling point in the global market.

The quality assurance process doesn’t end at the factory gate. Chinese manufacturers often provide after-sales service and support, which includes warranty coverage and customer service. This ensures that even after the product has been purchased, the consumer can rely on the manufacturer to address any issues that may arise.

Innovation is also a key component of quality assurance. Chinese manufacturers are constantly seeking new ways to improve their products. This might involve developing new materials that are more durable or incorporating smart features that enhance the user experience. By staying ahead of the curve, these manufacturers are able to offer products that not only meet but exceed international standards.

The emphasis on quality in Chinese air fryer manufacturing is not just about meeting regulations; it’s about building trust with consumers. A product that is known for its quality is more likely to be purchased, recommended, and become a staple in homes around the world. This trust is earned through a combination of stringent quality control measures, ongoing innovation, and a commitment to customer satisfaction.

In conclusion, the quality assurance process in China’s air fryer industry is a complex and multifaceted endeavor. It involves a careful selection of materials, meticulous assembly, rigorous testing, adherence to international certifications, and a focus on continuous improvement. This dedication to quality is what sets Chinese air fryers apart in the global market, making them a preferred choice for consumers seeking reliable and high-performance kitchen appliances.

In the competitive landscape of kitchen appliances, customizing your air fryer to align with your brand’s identity is a strategic move that can set your product apart. Here’s how the process works, ensuring that each air fryer is not just a product but a reflection of your brand’s values and aesthetics.

Understanding Your Brand’s IdentityYour brand’s identity is the essence of what you stand for. It’s the combination of your values, mission, and the image you want to project to consumers. When it comes to air fryers, this identity can be translated into features, design, and functionality that resonate with your target audience.

Designing for Brand ConsistencyThe design phase is where your brand’s voice truly comes to life. This involves not just the visual appeal but also the usability of the air fryer. Whether it’s a sleek, modern look or a rustic, homely feel, the design must be consistent with your brand’s image. This could mean using specific colors, materials, or even incorporating unique features that are exclusive to your brand.

Functionality that Speaks VolumesFunctionality is key when it comes to air fryers. But it’s not just about the ability to cook with less oil; it’s about offering features that enhance the user experience and align with your brand’s promise. For instance, if your brand focuses on health and wellness, you might integrate smart features that track cooking times and temperatures, ensuring optimal results every time.

Brand Storytelling Through PackagingPackaging is another area where customization can make a significant impact. The box, the materials, the graphics—every element should tell a story about your brand. This could involve eco-friendly materials, clear messaging about the product’s benefits, or even interactive elements that engage the consumer before they even open the box.

Incorporating Brand-Specific FeaturesSome brands might opt for unique features that are exclusive to their air fryers. This could be a special cooking mode, a smart app integration, or even a unique design element that becomes a talking point. These features not only differentiate the product but also reinforce the brand’s identity in the consumer’s mind.

Collaboration with Design AgenciesTo ensure that the air fryer design aligns perfectly with your brand, many companies turn to design agencies. These agencies specialize in creating products that not only look great but also feel right for the brand. They bring a fresh perspective and a wealth of experience to the table, helping to refine the design and make it as impactful as possible.

Iterative Prototyping and TestingBefore the final product hits the shelves, it goes through an iterative process of prototyping and testing. This involves creating multiple versions of the air fryer, each with slight variations in design or functionality, to see what resonates best with your target market. This stage is crucial for fine-tuning the product to ensure it meets both your brand’s standards and customer expectations.

Branding Through After-Sales ServiceOnce the air fryer is in the hands of consumers, the branding continues through after-sales service. This includes everything from customer support to warranty services. By providing exceptional service, your brand can build trust and loyalty, reinforcing the customer’s connection to your brand.

Marketing and Promotional MaterialsCustomization extends beyond the physical product to marketing and promotional materials. From social media posts to point-of-sale displays, these materials should all reflect your brand’s identity. This consistency in messaging helps to strengthen brand recognition and recall.

Feedback Loop and Continuous ImprovementFinally, a successful customization process involves a feedback loop. Collecting customer feedback and using it to make continuous improvements ensures that your air fryer remains relevant and aligned with your brand’s evolving identity. This approach keeps your product fresh and your brand at the forefront of consumer minds.

In the fast-paced world of kitchen appliances, a successful Original Design Manufacturer (ODM) project can set a brand apart from the competition. Let’s delve into a case study that showcases a remarkable 30-day air fryer ODM project, highlighting the key steps, challenges, and triumphs along the way.

The client, a budding brand in the health and wellness sector, approached us with a clear vision: to create an air fryer that not only performed exceptionally but also resonated with consumers’ desire for a healthier lifestyle. The brief was simple yet ambitious—design and produce a high-quality air fryer within a tight 30-day timeline.

Day 1: Understanding the BriefThe project kicked off with a detailed briefing session. We delved into the client’s brand identity, target market, and the specific features they wanted in the air fryer. It was essential to align our design and production process with the client’s brand values and market expectations.

Day 2-5: Conceptualization and DesignOur design team brainstormed and sketched multiple concepts, focusing on ease of use, compact size, and innovative features. We considered the latest trends in kitchen appliances and how our design could stand out. After several iterations, we settled on a sleek, minimalist design that incorporated advanced technology and a user-friendly interface.

Day 6-10: Prototyping and TestingOnce the design was finalized, our engineers began crafting prototypes. We used high-quality materials to ensure durability and reliability. Each prototype went through rigorous testing for performance, safety, and energy efficiency. We also sought feedback from potential end-users to refine the design further.

Day 11-15: Iterations and RefinementBased on the feedback from testing, we made several adjustments to the prototype. This involved tweaking the design for better ergonomics, improving the cooking capabilities, and ensuring the air fryer was easy to clean. The iterative process was crucial in honing the product to meet the client’s expectations.

Day 16-20: Tooling and Production SetupWith the final design in place, we moved on to the tooling phase. This involved creating molds and fixtures necessary for mass production. Our production team worked tirelessly to ensure the tools were precise and efficient. Simultaneously, we set up the production line, optimizing it for speed and quality control.

Day 21-25: Pilot ProductionBefore full-scale production, we initiated a pilot run to test the production process. This allowed us to identify any potential issues and address them promptly. The pilot batch also served as a reference for quality control measures, ensuring consistency in every unit produced.

Day 26-30: Full-Scale Production and Quality ControlWith the pilot run successful, we transitioned to full-scale production. Our team monitored the production line closely, ensuring each air fryer met the stringent quality standards. We implemented a robust quality control system, including in-process checks and final inspections, to guarantee the product’s excellence.

On the 30th day, we delivered the final batch of air fryers to the client. The entire project was completed on time, and the client was thrilled with the result. The air fryer exceeded their expectations, and the brand was ready to hit the market with a product that stood out from the crowd.

This case study highlights the importance of a well-planned and executed ODM project. From understanding the client’s vision to final delivery, every step was crucial in ensuring the success of the project. The collaboration between the client and our team was key, and the end result was a product that not only met but exceeded expectations.

The air fryer landscape is ever-evolving, and as we approach the end of this journey, it’s important to reflect on the key factors that can lead to success in this competitive market. Confidence in navigating this landscape comes from understanding the nuances of consumer preferences, technological advancements, and strategic partnerships.

Consumer Behavior Insights: The shift towards healthier cooking methods has propelled the air fryer market forward. Consumers are increasingly aware of the health benefits, such as lower oil usage and the ability to cook a variety of foods with minimal fat. By staying attuned to these trends, brands can design air fryers that cater to this growing demand for healthier living.

Technological Advancements: Innovation in air fryer technology is key to staying ahead of the curve. Features like programmable settings, larger capacities, and energy efficiency are becoming standard expectations. Brands that invest in research and development to push the boundaries of what air fryers can do are more likely to capture the interest of tech-savvy consumers.

Strategic Partnerships: Collaborating with the right suppliers and manufacturers can significantly impact a brand’s success. Partnerships that allow for customization, flexibility, and high-quality production are invaluable. These alliances can also provide insights into market demands and help streamline the product development process.

Brand Storytelling: In a crowded marketplace, brand identity and storytelling play a crucial role. A compelling brand story that resonates with consumers can create a loyal customer base. Whether it’s emphasizing eco-friendly practices, supporting local communities, or highlighting the air fryer’s ability to simplify busy lifestyles, a strong narrative can set a brand apart.

Marketing and Distribution: How a brand chooses to market its air fryers and where it distributes them can greatly influence its success. Social media campaigns, influencer partnerships, and targeted advertising can create buzz and generate interest. Additionally, understanding which retail channels are most effective for reaching your target audience is essential.

Customer Service: Exceptional customer service is the cherry on top of a great air fryer. Brands that provide prompt and helpful support build trust and foster long-term relationships with customers. Investing in a responsive customer service team and easy-to-access support channels can be the difference between a satisfied customer and a dissatisfied one.

Long-Term Vision: Confidence in the air fryer landscape also comes from having a clear long-term vision. Brands that plan for the future by anticipating market changes, evolving with consumer needs, and adapting to new technologies will be better positioned to thrive in the long run.

Sustainability: The growing focus on sustainability is another area where brands can stand out. By considering the environmental impact of their products and packaging, and by promoting recycling and eco-friendly practices, brands can appeal to environmentally conscious consumers.

Global Expansion: As the air fryer market continues to grow, there are opportunities to expand globally. Understanding different markets, local regulations, and consumer preferences in various regions can open doors to new customers and revenue streams.

Innovation and Continuous Improvement: Staying ahead requires a commitment to innovation and continuous improvement. Brands that are willing to experiment with new features, materials, and designs are more likely to capture the attention of customers and maintain their competitive edge.

Customer Feedback: Actively seeking and responding to customer feedback is vital. It provides valuable insights into what’s working and what’s not, allowing brands to make informed decisions about future product iterations and enhancements.

Legal and Compliance: Ensuring that air fryers meet international safety standards and certifications is non-negotiable. Compliance with legal requirements is the foundation upon which consumer trust is built.

By keeping these factors in mind, brands can confidently navigate the complex and dynamic air fryer landscape, building a solid foundation for future success. Whether it’s through technological innovation, strategic partnerships, or a strong focus on customer satisfaction, the path to leading in the air fryer market is clear—stay adaptable, customer-centric, and forward-thinking.