Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

The world of kitchen appliances has evolved, and with it, the demand for versatile and efficient products. One such innovation that has gained traction is the 120V/240V dual voltage sandwich press. This compact, multipurpose appliance has captured the interest of both consumers and manufacturers alike, offering a unique blend of functionality and convenience. As we delve into the market dynamics, we’ll explore the innovative features that set these sandwich presses apart, the opportunities for OEM partnerships, current market trends, and the compliance challenges that come with catering to a global audience. The future of the dual voltage sandwich press market looks promising, and understanding its trajectory is crucial for anyone looking to capitalize on this burgeoning niche.

The dual voltage sandwich press market has emerged as a significant segment within the global kitchen appliances industry, offering a versatile solution for consumers across different regions. With the increasing demand for convenience and high-quality cooking experiences, this market has seen a surge in innovation and growth. In this dynamic landscape, the 120V/240V dual voltage sandwich presses have become a sought-after product, catering to a diverse customer base.

The dual voltage capability of these sandwich presses is a game-changer, allowing users to enjoy the perfect grilled sandwich regardless of their location. Whether in the United States, Europe, or Asia, these presses ensure that users can rely on consistent performance without the need for voltage adapters or transformers.

The market for dual voltage sandwich presses is driven by several key factors. Firstly, the growing trend of home cooking has led to a higher demand for kitchen appliances that can replicate restaurant-quality results. Secondly, the rise of health-conscious consumers has shifted preferences towards healthier cooking methods, such as grilling, which the dual voltage sandwich presses excel at. Lastly, the globalization of food culture has introduced a variety of sandwich styles that require specific cooking techniques, making the dual voltage sandwich press a versatile tool for any kitchen.

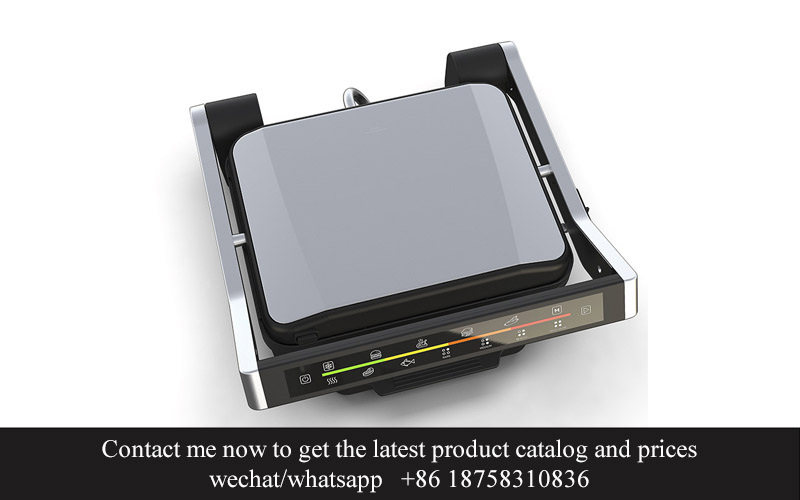

In terms of design, the 120V/240V dual voltage sandwich presses are often equipped with non-stick surfaces, adjustable temperature controls, and convenient features like removable drip trays and easy-to-clean components. These design elements not only enhance the user experience but also contribute to the product’s popularity.

The global kitchen appliances industry has been witnessing a steady increase in the adoption of smart technology. Dual voltage sandwich presses are no exception, with many models now featuring digital displays, preset cooking programs, and even Bluetooth connectivity for remote control. This integration of smart technology not only adds convenience but also provides users with a more personalized cooking experience.

When it comes to OEM (Original Equipment Manufacturer) opportunities, the dual voltage sandwich press market presents a promising landscape for manufacturers and suppliers. By partnering with established brands, OEMs can tap into a market that is continually expanding due to the growing number of sandwich shops, cafes, and home kitchens seeking high-quality appliances.

OEMs also benefit from the ability to customize their offerings based on market trends and customer preferences. For instance, certain regions may have a preference for specific sandwich styles or cooking temperatures, allowing OEMs to tailor their products accordingly. This flexibility is crucial in a market that is as dynamic as the dual voltage sandwich press industry.

Market trends indicate that the dual voltage sandwich press market is poised for further growth. Consumer demand for convenience, health, and innovation continues to drive the industry forward. Additionally, the rise of e-commerce has made it easier for consumers to access these products, further fueling market expansion.

In conclusion, the dual voltage sandwich press market is a thriving sector within the kitchen appliances industry. With its versatility, innovative features, and growing consumer base, it offers a wealth of opportunities for OEMs and manufacturers. As the market continues to evolve, those who stay attuned to consumer needs and market trends will be well-positioned to capitalize on this dynamic and lucrative market.

In today’s rapidly evolving culinary landscape, the demand for versatility and convenience in kitchen appliances has surged. This shift has led to a significant rise in the popularity of dual voltage sandwich presses, specifically those designed for 120V and 240V systems. Understanding the need for such appliances is crucial for both manufacturers and consumers alike.

The global market is witnessing a surge in the number of households opting for kitchen gadgets that can cater to various power requirements. This is particularly true for countries where electricity standards differ, as dual voltage appliances ensure compatibility and ease of use. For instance, in the United States, where most homes operate on a 120V power supply, and in countries like the United Kingdom, where 240V is the standard, dual voltage sandwich presses bridge the gap.

One of the primary reasons for the increasing need for 120V/240V dual voltage sandwich presses is the growing international travel trend. Many individuals and families are frequently moving across borders, and with them, their culinary preferences. Having a sandwich press that can operate in different voltage systems allows for the convenience of enjoying familiar recipes, regardless of location.

Moreover, the global kitchen appliances industry has seen a significant transformation, with a shift towards healthier eating habits. Sandwich presses have become a staple in many kitchens, as they offer a quick and easy way to prepare nutritious meals at home. The dual voltage feature ensures that these appliances can be used in various settings, from small apartments to large homes, catering to the diverse needs of health-conscious consumers.

Another factor driving the demand for dual voltage sandwich presses is the rise of food enthusiasts and home chefs. These individuals often seek out high-quality appliances that can produce professional-grade results. With dual voltage models, they can enjoy consistent performance across different power grids, ensuring that their culinary creations are never compromised.

In addition to these factors, the ease of use and safety features of dual voltage sandwich presses cannot be overlooked. Modern designs often include safety locks and non-stick surfaces, making them user-friendly and easy to clean. The dual voltage capability also allows for greater flexibility when it comes to cooking temperatures, as the appliance can be adjusted to meet specific cooking needs.

For manufacturers, the demand for dual voltage sandwich presses presents a unique opportunity. By catering to the needs of a global market, companies can tap into a wider customer base. This also means that they must focus on producing high-quality products that not only meet the diverse voltage requirements but also offer innovative features and durability.

The environmental impact of kitchen appliances is also a crucial consideration. With the growing emphasis on sustainability, dual voltage sandwich presses can contribute to a lower carbon footprint by reducing the need for additional power conversions or purchases of multiple appliances for different voltage systems.

In the realm of innovation, the dual voltage sandwich press market is ripe for new ideas. Manufacturers can explore the integration of smart technology, such as WiFi connectivity, to allow for remote control and monitoring of the appliance. This would not only enhance the user experience but also make it possible to offer personalized cooking recommendations based on local power conditions.

Finally, the need for 120V/240V dual voltage sandwich presses is underscored by the desire for culinary exploration. As people become more adventurous with their food, they seek out appliances that can help them replicate recipes from around the world. Dual voltage sandwich presses offer this opportunity, making it easier for enthusiasts to experiment with different cooking techniques and ingredients.

In conclusion, the need for 120V/240V dual voltage sandwich presses is multifaceted, stemming from the global nature of travel, the shift towards healthier eating habits, the rise of food enthusiasts, and the increasing importance of environmental sustainability. As the kitchen appliances industry continues to grow, addressing these needs will be key to the success of dual voltage sandwich press manufacturers.

The global kitchen appliances industry has witnessed a remarkable transformation over the years, evolving from simple, functional devices to sophisticated, innovative tools that enhance our daily lives. This surge in growth can be attributed to several key factors that have shaped the landscape of this dynamic market.

Technological Advancements: The integration of cutting-edge technology has been a cornerstone in the expansion of the kitchen appliances sector. Smart appliances equipped with IoT capabilities, for instance, allow users to monitor and control their devices remotely, offering convenience and efficiency like never before.

Urbanization and Changing Lifestyles: As cities continue to grow, so does the demand for compact, multifunctional kitchen appliances. The rise of urban dwellers seeking to maximize space has led to the development of sleek, space-saving models that cater to this demographic.

Health and Wellness Trends: There’s been a significant shift towards healthier eating habits, which has spurred the demand for kitchen appliances that can help consumers prepare nutritious meals at home. Slow cookers, juicers, and air fryers have become increasingly popular as they offer healthier alternatives to traditional cooking methods.

Sustainability and Energy Efficiency: Environmental concerns have pushed manufacturers to focus on sustainable practices and energy-efficient designs. Appliances that consume less energy not only reduce utility bills but also contribute to a greener planet, aligning with the values of eco-conscious consumers.

Globalization and Cross-Cultural Influence: The interconnectedness of the world has led to a fusion of culinary traditions, influencing the types of kitchen appliances that are in demand. International flavors have sparked a demand for specialized appliances that can replicate traditional cooking techniques from various cultures.

E-commerce and Online Shopping: The rise of e-commerce has transformed the way consumers purchase kitchen appliances. Online marketplaces provide a vast array of options, competitive pricing, and easy access to products from around the world, making it more convenient for consumers to explore and purchase the latest innovations.

Customization and Personalization: Consumers today are looking for appliances that not only perform well but also reflect their personal style and preferences. Brands are responding by offering customizable options, from color choices to unique features, allowing customers to tailor their kitchen appliances to their specific needs.

Regulatory Compliance and Safety Standards: The kitchen appliances industry must adhere to stringent safety and regulatory standards across different regions. This has necessitated continuous innovation in design and materials to ensure compliance while maintaining product quality.

Market Expansion in Emerging Economies: The expansion of the middle class in emerging economies has opened up new markets for kitchen appliances. As these regions experience economic growth, there’s a corresponding increase in demand for modern kitchen technology.

Collaboration and Partnerships: To stay competitive, manufacturers are forming strategic partnerships, merging their expertise to create groundbreaking products. These collaborations often lead to the development of innovative solutions that push the boundaries of what’s possible in kitchen appliances.

Culinary Education and Cooking Shows: The popularity of culinary education and cooking shows has sparked a renewed interest in cooking at home. As aspiring chefs and home cooks seek to improve their skills, they turn to high-quality kitchen appliances to enhance their culinary experiences.

Marketing and Branding Strategies: Effective marketing and branding have played a crucial role in the success of the kitchen appliances industry. Brands that tell compelling stories and connect with consumers on an emotional level have a competitive edge in this highly competitive market.

The rise of the global kitchen appliances industry is a testament to the power of innovation, consumer demand, and the ever-evolving landscape of technology and culture. As the industry continues to grow, it will undoubtedly bring forth new challenges and opportunities, shaping the future of how we cook and live.

In the ever-evolving landscape of kitchen appliances, the 120V/240V dual voltage sandwich press has emerged as a game-changer. These versatile devices are not just about pressing sandwiches; they offer a range of innovative features that cater to the diverse needs of modern consumers. Let’s delve into some of these standout characteristics.

The compact design of these sandwich presses is a testament to their innovation. They are sleek and space-saving, making them perfect for kitchens of all sizes. Their ability to fold flat or stand vertically when not in use is a nod to practicality and convenience.

One of the most notable features is the adjustable heat settings. Users can choose from a variety of temperatures to achieve the perfect level of crispiness on their sandwiches. Whether you prefer a slightly toasted outside with a soft, warm interior or a golden-brown crust, these presses provide the precision needed to satisfy even the pickiest sandwich enthusiast.

Many models come equipped with non-stick surfaces, ensuring that your creations come out effortlessly and without the need for excessive oil or butter. This not only simplifies the cleaning process but also adds to the health benefits by reducing the fat content in your sandwiches.

The inclusion of a locking mechanism is another clever feature. It prevents the sandwich from sliding around during the pressing process, ensuring even cooking and minimizing the risk of burning. This is particularly useful for those who are short on time or prefer a hands-free cooking experience.

The presence of a drip tray is a thoughtful addition. It catches any excess oil or juices that might leak from the sandwich, keeping your countertop clean and your kitchen organized. This is especially appreciated by those who like to make a variety of sandwiches with different ingredients.

Some sandwich presses take innovation a step further by offering a variable press time. Users can set the timer to ensure that their sandwiches are cooked to perfection without the risk of overcooking. This feature is especially valuable for those who might not be as familiar with the timing required for different types of bread and fillings.

Safety features are also a priority in these appliances. Many models come with cool-touch handles and bases, preventing accidental burns. Additionally, some presses are designed with automatic shut-off mechanisms, which activate if the device is left unattended for an extended period, adding an extra layer of safety.

In terms of versatility, these sandwich presses are not limited to just sandwiches. They can also be used to press other foods like burgers, paninis, and even tofu or tempeh for a vegan twist. The adjustable plates often have a non-stick surface on both sides, making them suitable for a variety of cooking methods.

The digital displays on some models are not just for show. They provide real-time temperature readings and allow users to monitor the cooking process, ensuring that the sandwich is cooked to the desired level of doneness. This is particularly useful for those who enjoy experimenting with different types of bread and fillings.

For those who are health-conscious, the ability to control the amount of oil used is a significant feature. The non-stick surfaces and adjustable heat settings make it easier to cook with less fat, contributing to a healthier lifestyle.

The inclusion of a user manual and recipe book is a bonus for those who are new to using a sandwich press. It provides step-by-step instructions and a collection of recipes to inspire new sandwich creations.

In conclusion, the innovative features of 120V/240V dual voltage sandwich presses are designed to enhance the cooking experience, offer convenience, and cater to a wide range of preferences. From their compact design to their versatile functionality, these appliances are a testament to the ongoing advancements in kitchen technology.

In the ever-evolving landscape of kitchen appliances, the dual voltage sandwich press sector has emerged as a fertile ground for Original Equipment Manufacturers (OEMs) to capitalize on. Here, we delve into the numerous opportunities that this niche market presents.

The adaptability of dual voltage models is a key draw for OEMs. With the ability to operate seamlessly across various regions, these presses cater to a global audience. This means OEMs can tap into multiple markets without the need for extensive modifications, saving both time and resources.

Customization is another opportunity that OEMs can leverage. As consumer preferences vary widely, offering a range of designs, functionalities, and features allows OEMs to tailor their products to different segments. This not only opens doors to new customers but also fosters brand loyalty and market differentiation.

Quality control remains a cornerstone in the success of any OEM. The dual voltage sandwich press sector demands precision engineering to ensure reliability and safety. OEMs that can demonstrate their commitment to high-quality standards will find a competitive edge in a market where consumer trust is paramount.

Innovation is a driving force in the kitchen appliances industry. OEMs that can introduce new features, such as programmable settings, non-stick surfaces, or energy-efficient designs, stand out in a crowded market. These innovations not only enhance the user experience but also contribute to the sustainability of the appliances.

Partnerships with local suppliers and manufacturers can be a game-changer for OEMs. By collaborating with regional entities, OEMs can benefit from cost-effective production, reduce lead times, and establish a strong local presence. This approach is particularly valuable in markets where distribution networks are complex.

The dual voltage sandwich press sector is also ripe for international collaborations. OEMs that can forge alliances with global brands can leverage their distribution channels and market expertise. This can lead to expanded reach and increased brand visibility on a global scale.

As the demand for healthier eating habits grows, OEMs have the chance to integrate health-conscious features into their sandwich presses. This could include features that promote healthier cooking methods or even provide nutritional information to users.

Sustainability is a hot topic in today’s market, and OEMs can capitalize on this trend by designing eco-friendly sandwich presses. This could involve using recycled materials, ensuring energy efficiency, or promoting a longer lifespan for the appliances.

The rise of e-commerce has opened new avenues for OEMs. By offering their dual voltage sandwich presses online, OEMs can tap into a global customer base without the need for physical stores. This digital marketplace provides a platform for direct-to-consumer sales, reducing overhead costs and increasing profit margins.

Lastly, the opportunity for continuous improvement is vast in the dual voltage sandwich press sector. OEMs that stay abreast of consumer feedback and technological advancements can make iterative updates to their products, ensuring they remain relevant and competitive.

From adaptability and customization to quality control and innovation, the dual voltage sandwich press sector is a treasure trove of opportunities for OEMs. By navigating these chances with strategic planning and a customer-centric approach, OEMs can carve out a niche for themselves in this dynamic market.

In recent years, the kitchen appliances market has witnessed a surge in innovation and consumer demand. Understanding the current market trends and consumer preferences is crucial for players in the industry, especially when it comes to products like the 120V/240V dual voltage sandwich presses. Here’s a breakdown of the key trends and preferences shaping this sector:

The rise of health-conscious consumers has led to a growing interest in home cooking and baking. People are looking for ways to prepare nutritious meals without compromising on taste or convenience. This shift has created a demand for kitchen appliances that offer both functionality and health benefits.

Modern lifestyles are fast-paced, and convenience is king. Consumers are increasingly seeking appliances that can help them save time while still delivering high-quality results. The dual voltage sandwich presses cater to this need by allowing users to quickly and easily make a variety of sandwiches, burgers, and other food items.

Eco-consciousness is another driving force in the kitchen appliances market. Consumers are more likely to purchase products that are energy-efficient and sustainable. Dual voltage sandwich presses that are designed with energy-saving features and environmentally friendly materials are likely to appeal to this segment of the market.

Smart technology integration has become a norm in many industries, and the kitchen appliances sector is no exception. Users are looking for appliances that can be controlled remotely, have programmable settings, or offer connectivity with other smart home devices. These features not only enhance convenience but also provide users with the ability to customize their cooking experience.

Portability is a significant factor for many consumers. They seek appliances that are compact, lightweight, and easy to store. Dual voltage sandwich presses that are designed to be portable, perhaps with foldable components or compact designs, are more likely to find a place in consumers’ kitchens.

Customization and personalization are becoming more important as consumers look for products that reflect their individual tastes and needs. Features like adjustable heating elements, non-stick surfaces, and various press patterns allow users to create a wide range of sandwich styles, from classic ham and cheese to gourmet creations.

Safety is a paramount concern for any appliance, and dual voltage sandwich presses are no different. Modern presses come with features like automatic shut-off, temperature control, and safety guards to prevent accidents. Consumers are drawn to products that prioritize their well-being and provide peace of mind.

The market for dual voltage sandwich presses is also influenced by the rise of influencer culture and social media. As influencers share their cooking experiences and favorite kitchen gadgets, they can significantly impact consumer purchasing decisions. Brands that leverage this trend by partnering with influencers or creating engaging content can see a boost in sales.

As the global kitchen appliances industry continues to evolve, there’s a growing preference for products that offer a blend of traditional cooking methods with modern technology. Dual voltage sandwich presses that combine the nostalgic appeal of classic appliances with the latest technological advancements are poised to capture the interest of consumers who appreciate a touch of nostalgia with their modern convenience.

In conclusion, the market trends and consumer preferences in the dual voltage sandwich press sector are diverse and multifaceted. By staying attuned to these trends and preferences, manufacturers and OEMs can develop products that not only meet the needs of today’s consumers but also anticipate future demands. This approach is key to maintaining a competitive edge and ensuring long-term success in the dynamic kitchen appliances market.

In the realm of OEM partnerships, the dual voltage sandwich press sector has seen some remarkable collaborations that have not only shaped the market but also driven innovation and growth. Let’s delve into a few case studies that highlight successful OEM relationships:

The collaboration between TechGrill and Global Sandwich Solutions began with a shared vision of creating a versatile and efficient dual voltage sandwich press. TechGrill, known for its state-of-the-art kitchen appliances, brought advanced technology and design expertise to the table, while Global Sandwich Solutions provided in-depth knowledge of the market and customer needs. The result was a line of sandwich presses that could seamlessly switch between 120V and 240V, catering to both domestic and international markets.

One of the standout features of this partnership was the integration of smart technology. The sandwich press featured a user-friendly interface that allowed for precise temperature control and time settings, ensuring consistent results every time. This innovation was a direct response to consumer demand for convenience and quality, and it paid off in spades. The product line quickly gained traction, with customers praising the ease of use and the delicious outcomes.

Another successful OEM partnership is that between Elite Appliances and World Sandwich Co. Elite Appliances, a leader in commercial kitchen equipment, paired their engineering prowess with World Sandwich Co.’s understanding of the foodservice industry. The outcome was a commercial-grade dual voltage sandwich press that could withstand heavy use while still delivering a perfect sandwich every time.

What made this partnership unique was the focus on sustainability. Both companies recognized the importance of reducing energy consumption and minimizing the environmental footprint. The resulting sandwich press was not only energy-efficient but also featured a durable, eco-friendly design. This approach resonated with both consumers and businesses looking to align their operations with global sustainability goals.

A third case study involves FreshBake and KitchenCraft. FreshBake, a boutique manufacturer of home kitchen appliances, sought to expand its product line with a dual voltage sandwich press that could appeal to a broader market. They turned to KitchenCraft, a company known for its custom OEM solutions. Together, they developed a compact, stylish sandwich press that could be easily integrated into any kitchen setting.

The key to this partnership was the emphasis on versatility. The sandwich press was designed to cater to both casual home cooks and serious sandwich enthusiasts. It featured a non-stick cooking surface, a sleek design, and easy-to-clean components, making it a practical choice for those who value convenience. The success of this partnership was evident in the positive feedback from customers who appreciated the balance between functionality and aesthetics.

In yet another instance, SmartGrill and LocalBites joined forces to create a dual voltage sandwich press that could be customized to local tastes. SmartGrill, with its focus on smart kitchen technology, brought cutting-edge features such as Bluetooth connectivity and mobile app integration. LocalBites, a company specializing in regional food markets, ensured that the press could accommodate various bread types and filling options.

The partnership resulted in a product that was not only technologically advanced but also culturally sensitive. Consumers were delighted to find a sandwich press that could deliver both their favorite local flavors and the latest in smart kitchen technology. This case study underscores the importance of understanding local markets and consumer preferences when developing OEM products.

Each of these case studies demonstrates the power of successful OEM partnerships in the dual voltage sandwich press sector. By combining technical expertise, market knowledge, and a commitment to innovation, these collaborations have led to products that not only meet but exceed consumer expectations. As the industry continues to evolve, it’s clear that these strategic alliances will play a crucial role in shaping the future of kitchen appliances.

In the ever-evolving landscape of the kitchen appliances industry, regulatory considerations and compliance have become paramount for both manufacturers and consumers. Ensuring that products meet the necessary standards is not just about safety; it’s about trust and credibility. Here’s a closer look at the key aspects of regulatory compliance in the dual voltage sandwich press sector.

The Importance of Safety StandardsSafety is the cornerstone of regulatory compliance. For dual voltage sandwich presses, adherence to international safety standards such as UL (Underwriters Laboratories) or CE (Conformité Européenne) is crucial. These standards ensure that the appliances are designed and manufactured to prevent electrical hazards, overheating, and fire risks.

Certification and TestingCertification processes involve rigorous testing to verify that products meet specific regulatory requirements. For dual voltage sandwich presses, this includes electrical safety testing, material integrity checks, and user interface evaluations. The certification process can be lengthy and costly, but it’s a necessary step to gain market access and consumer trust.

Global Harmonization of StandardsThe global kitchen appliances market is becoming increasingly interconnected. As such, harmonizing regulations across different regions is essential. This harmonization ensures that products can be sold in multiple markets without the need for significant modifications. For dual voltage sandwich presses, this means meeting both North American (NEMA, UL) and European (EN, CE) standards.

Energy Efficiency RegulationsEnergy efficiency is a growing concern worldwide. Many countries have implemented energy efficiency regulations that require appliances to meet certain energy consumption criteria. Dual voltage sandwich presses must be designed to optimize energy use, not only to comply with these regulations but also to appeal to environmentally conscious consumers.

Environmental RegulationsEnvironmental regulations are becoming stricter, with a focus on reducing the environmental impact of products throughout their lifecycle. This includes considerations for the materials used in manufacturing, the energy consumed during use, and the disposal of the product at the end of its life. Dual voltage sandwich press manufacturers must ensure that their products are recyclable and environmentally friendly.

Labeling and InformationClear and accurate labeling is essential for consumer protection. Dual voltage sandwich presses must include information on voltage compatibility, safety warnings, and usage instructions. This ensures that consumers understand how to safely operate the appliance and what to expect in terms of performance and safety.

Compliance with Local LawsEach country has its own set of laws and regulations that must be adhered to. This includes import/export restrictions, customs duties, and local business practices. For dual voltage sandwich presses, understanding and complying with these local laws is critical for successful market entry and ongoing operations.

Consumer Trust and Brand ReputationCompliance with regulations is not just about meeting legal requirements; it’s about building trust with consumers. When a product is certified and meets all necessary standards, it signals to consumers that the manufacturer is committed to quality and safety. This can significantly enhance brand reputation and customer loyalty.

Continuous Monitoring and ImprovementRegulatory compliance is an ongoing process. New standards are introduced, and existing ones are updated regularly. Manufacturers of dual voltage sandwich presses must stay informed about these changes and continuously monitor their products to ensure ongoing compliance. This might involve product redesigns, component upgrades, or changes in manufacturing processes.

In conclusion, regulatory considerations and compliance in the dual voltage sandwich press sector are multifaceted. They encompass safety, energy efficiency, environmental impact, and consumer protection. By navigating these complexities with diligence and foresight, manufacturers can not only meet legal obligations but also foster a positive relationship with their customers and the broader market.

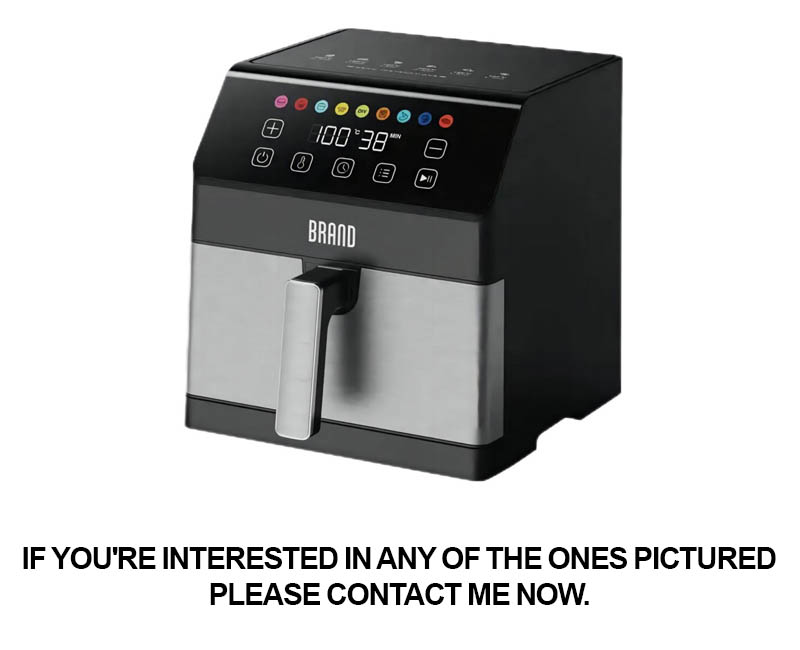

The dual voltage sandwich press market is on the rise, and with it comes a wave of innovation and technological advancements. These presses, designed to operate on both 120V and 240V electrical systems, offer a versatile solution for global consumers. Let’s delve into the innovative features that make these sandwich presses stand out.

Universal Compatibility: One of the most significant features of the 120V/240V dual voltage sandwich press is its universal compatibility. This means that regardless of whether you’re in the United States, Europe, or Asia, you can use the same appliance without worrying about voltage compatibility issues. This feature alone has opened up a vast global market for these presses.

Advanced Heat Distribution: Modern dual voltage sandwich presses are equipped with advanced heat distribution systems. These systems ensure that the heat is evenly distributed across the cooking surface, resulting in perfectly cooked sandwiches every time. The precise temperature control allows users to achieve the desired level of crispiness on the outside and tenderness on the inside.

Non-Stick Coating: The cooking plates of these sandwich presses are often coated with a high-quality non-stick material. This not only makes cleaning easier but also ensures that the sandwiches don’t stick to the plates, preserving their shape and texture.

Safety Features: Safety is a top priority in the design of dual voltage sandwich presses. Many models come with features like automatic shut-off after a certain period of non-use, preventing overheating and reducing the risk of accidents. Additionally, some presses have cool-touch handles and a locking mechanism to prevent accidental opening while in use.

Versatility: While originally designed for making sandwiches, these presses have evolved to offer versatility. Many models can be used to cook a variety of foods, including paninis, wraps, and even pizzas. Some even come with additional attachments for grilling vegetables or making omelets.

Design and Aesthetics: The design of dual voltage sandwich presses has also seen significant advancements. Modern presses come in various sizes, shapes, and colors, catering to different kitchen aesthetics. Some models even feature sleek, modern designs that complement contemporary kitchen decor.

Ease of Use: These presses are designed with the user in mind. The controls are straightforward, and many models come with digital displays for precise temperature settings. The compact size and easy-to-clean surfaces make these appliances a breeze to use and maintain.

Portability: For those who love to cook but lack space, the dual voltage sandwich press offers a portable solution. Some models are lightweight and can be easily stored away when not in use, making them a great addition to small kitchens or dorm rooms.

Innovative Materials: The materials used in the construction of these presses have also improved. Many are made from durable, heat-resistant materials that can withstand high temperatures without warping or deforming.

Energy Efficiency: With the growing emphasis on sustainability, energy-efficient appliances are becoming more popular. Dual voltage sandwich presses often consume less energy than their single-voltage counterparts, contributing to a greener kitchen environment.

In conclusion, the innovative features of 120V/240V dual voltage sandwich presses have made them a favorite among cooks worldwide. From universal compatibility and advanced heat distribution to safety features and design aesthetics, these appliances offer a comprehensive solution for sandwich enthusiasts and culinary adventurers alike.

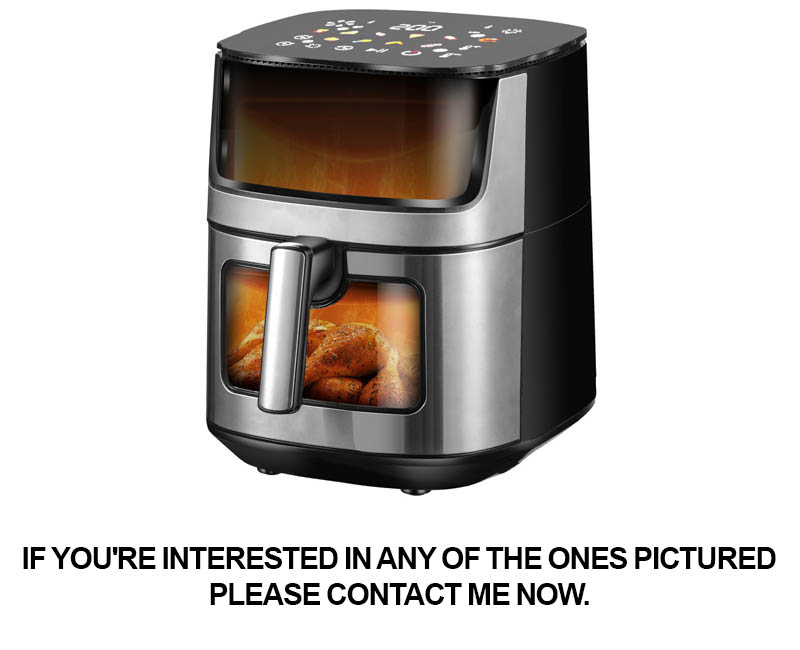

The dual voltage sandwich press market is a burgeoning sector that has seen a significant surge in demand. As consumers seek convenience and efficiency in their kitchen appliances, these versatile presses have become a staple in many homes. The market’s growth is not just driven by the increasing popularity of sandwiches but also by the innovation and customization that OEMs are bringing to the table. Here’s a closer look at the potential that this market holds.

In the realm of dual voltage sandwich presses, the ability to function on both 120V and 240V systems is a game-changer. It means that these appliances can cater to a wider global audience, as they are not confined to specific regions with a single voltage standard. This adaptability is crucial for OEMs looking to expand their reach and market share.

The dual voltage feature itself is just one aspect of the innovative features found in modern sandwich presses. Many models now come with non-stick surfaces that make cleanup a breeze, adjustable heat settings for perfect browning, and even built-in timers to ensure that your sandwiches are cooked to perfection. These features not only enhance the user experience but also set the stage for OEMs to offer unique selling points that differentiate their products from the competition.

When it comes to OEM opportunities, the dual voltage sandwich press sector is ripe with potential. Original Equipment Manufacturers (OEMs) can collaborate with brands to create customized solutions that cater to niche markets or specific consumer needs. For instance, a brand might seek an OEM to develop a compact model for small kitchens or a high-end model with advanced features for gourmet sandwich enthusiasts. The possibilities are vast, and OEMs that can adapt and innovate will find a fertile ground for growth.

Market trends and consumer preferences continue to evolve, and understanding these shifts is key to staying ahead in the dual voltage sandwich press market. Consumers are increasingly looking for smart appliances that not only simplify cooking but also integrate with their lifestyles. This means that OEMs need to focus on features like connectivity, allowing users to control their sandwich presses remotely via smartphones or other devices.

Case studies of successful OEM partnerships in the sandwich press sector often highlight the importance of collaboration and shared vision. For example, one such partnership involved an OEM working closely with a brand to develop a sandwich press that could also serve as a compact toaster oven. The result was a versatile appliance that appealed to both sandwich lovers and those who enjoy a variety of toasty treats. This kind of synergy can lead to groundbreaking products that resonate with consumers.

Regulatory considerations and compliance are non-negotiable in the global kitchen appliances industry. OEMs must ensure that their products meet the safety standards and regulations of the markets they intend to serve. This includes certifications for electrical safety, fire resistance, and user safety. Navigating these regulations can be complex, but it is essential for maintaining a good reputation and ensuring customer trust.

Looking ahead, the future of dual voltage sandwich presses appears to be bright. As technology advances, we can expect to see even more innovative features that enhance user experience. Smart appliances that can predict cooking times based on the type of bread or ingredients used are not far-fetched. Additionally, with the rise of eco-friendly products, we may see sandwich presses that are more energy-efficient and sustainable.

Conclusion: Seizing the Potential of the 120V/240V Sandwich Press Market

In conclusion, the dual voltage sandwich press market presents a world of opportunities for OEMs. By focusing on innovation, understanding market trends, forming successful partnerships, and ensuring compliance with regulations, OEMs can tap into a market that is growing and evolving. The key is to remain adaptable and responsive to consumer needs, while also pushing the boundaries of what a sandwich press can offer. With the right approach, OEMs can not only capture the market’s potential but also shape its future.